Fly ash silicate cement prepared by using CFBC desulphurized ash

A Portland cement and desulfurization ash technology, applied in cement production, etc., can solve the problems of low utilization rate of CFBC desulfurization ash, sulfur dioxide re-pollution, etc., and achieve the effects of easy promotion and use, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

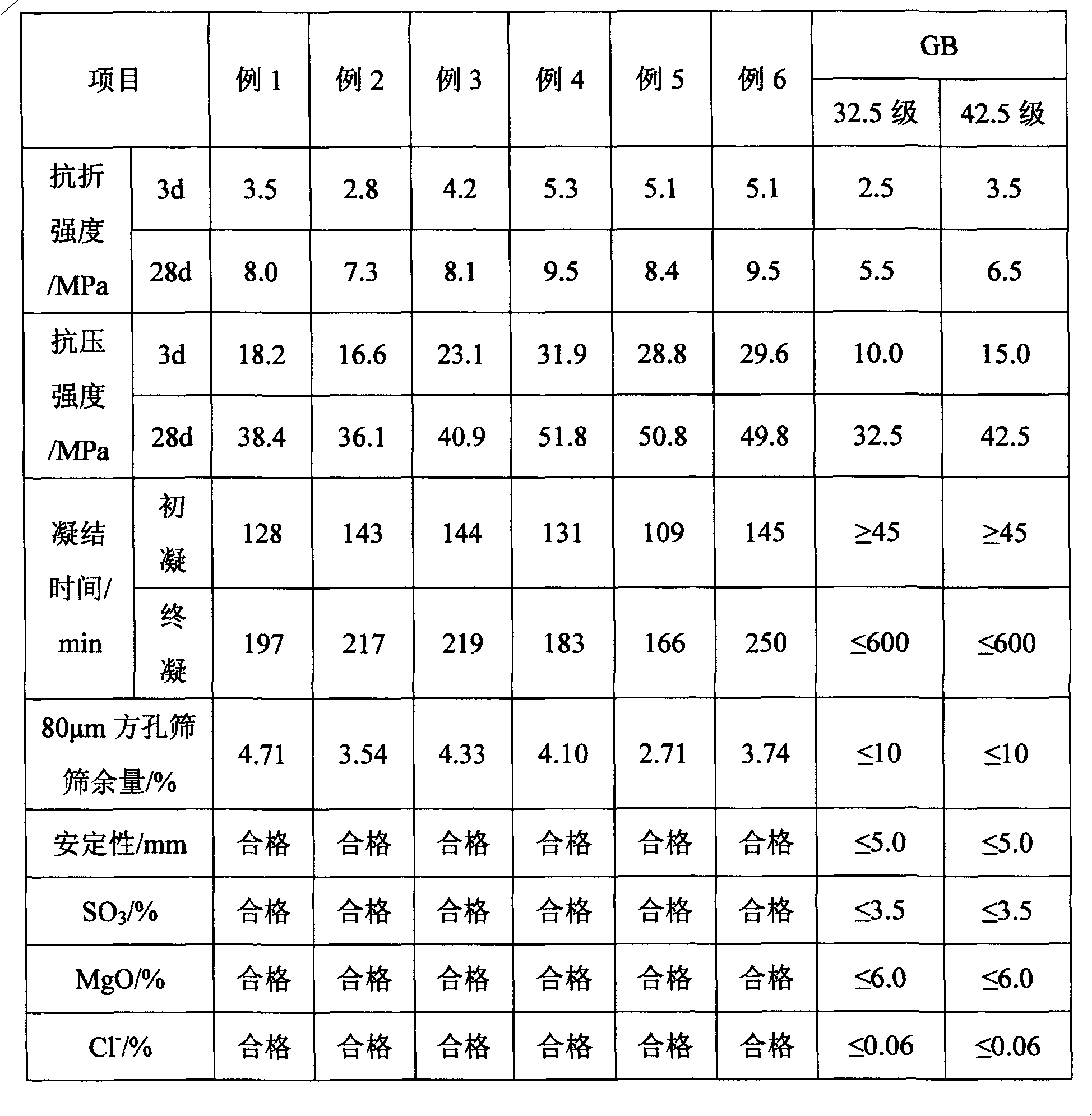

[0011] Components and proportions: CFBC desulfurization ash 40%, Portland cement clinker 56%, gypsum 4%.

[0012] Process: After mixing the components, grind them until the sieve residue of 80 μm is 4.71%, and then the 32.5 grade fly ash Portland cement is obtained.

[0013] Effect: See Table 1.

Embodiment 2

[0015] Components and proportions: CFBC desulfurization ash 50%, Portland cement clinker 45%, gypsum 5%.

[0016] Process: After mixing the components, grind them until the sieve residue of 80 μm is 3.54%, and then the 32.5 grade fly ash Portland cement is obtained.

[0017] Effect: See Table 1.

Embodiment 3

[0019] Components and proportions: CFBC desulfurization ash 30%, Portland cement clinker 65%, gypsum 5%.

[0020] Process: After mixing the components, grind them until the sieve residue of 80 μm is 4.33%, and then the 32.5 grade fly ash Portland cement is obtained.

[0021] Effect: See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com