Pre-heating device and pre-heating method of sulfate slag pellet ore

A technology of sulfuric acid slag pellets and preheating devices, which is applied in the direction of improving process efficiency, etc., and can solve problems such as corrosion of tail gas treatment equipment and easy formation of acid mist in flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

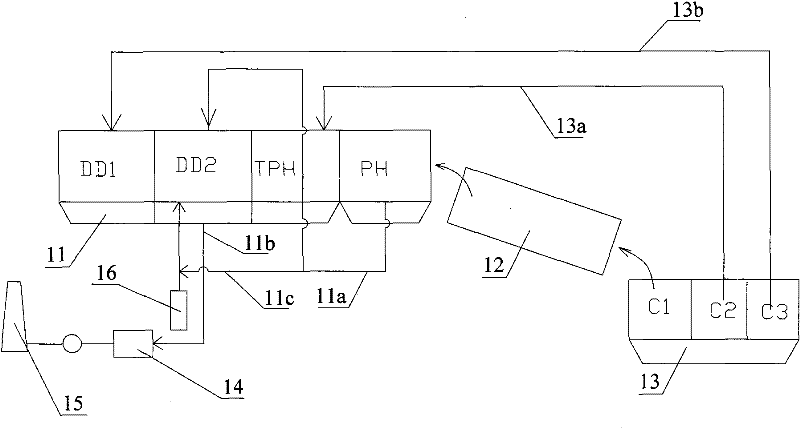

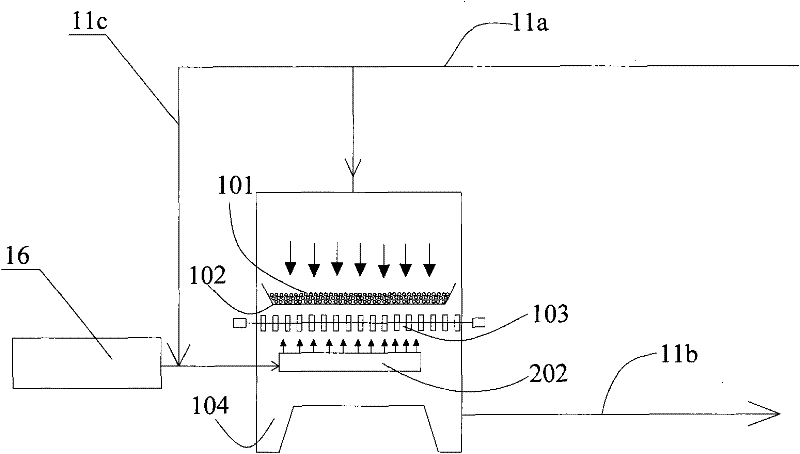

[0036] See figure 2 , is a schematic diagram of a specific embodiment of the pellet preheating device provided by the present invention. The pellet preheating device includes a grate machine 11, and the grate machine is divided into a first drying section DD1, a second drying section DD2, a first preheating section TPH, and a second preheating section from the feed end side. Section PH; between the second preheating section PH and the second drying section DD2, an eleventh air supply duct 11a is arranged, and the flue gas discharged from the second preheating section enters the second air supply duct 11a through the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com