Focus ring, plasma processing apparatus and plasma processing method

A technology of plasma and processing method, which is applied in the field of focus ring, plasma processing device and plasma processing, can solve the problems of increasing operating cost and reducing the operating rate of plasma processing device, and achieves the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

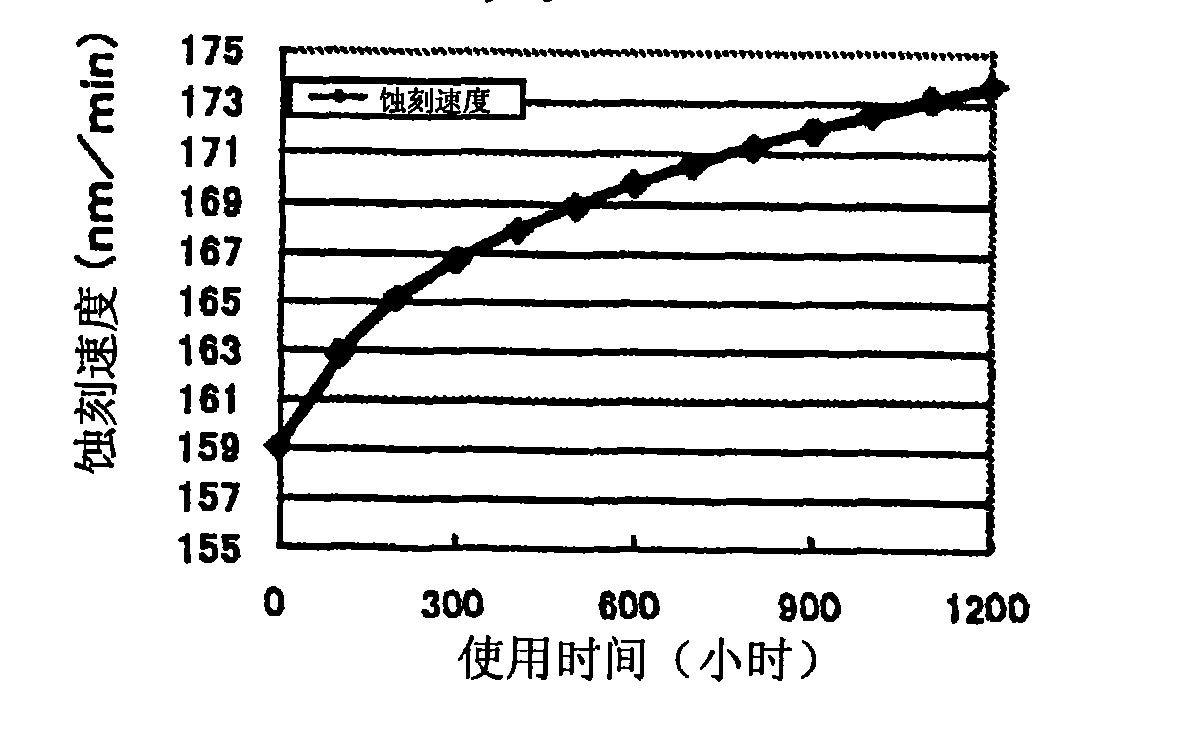

Examples

Embodiment Construction

[0029] Hereinafter, details of the focus ring, plasma processing apparatus, and plasma processing method of the present invention will be described with reference to the drawings, and embodiments thereof will be described.

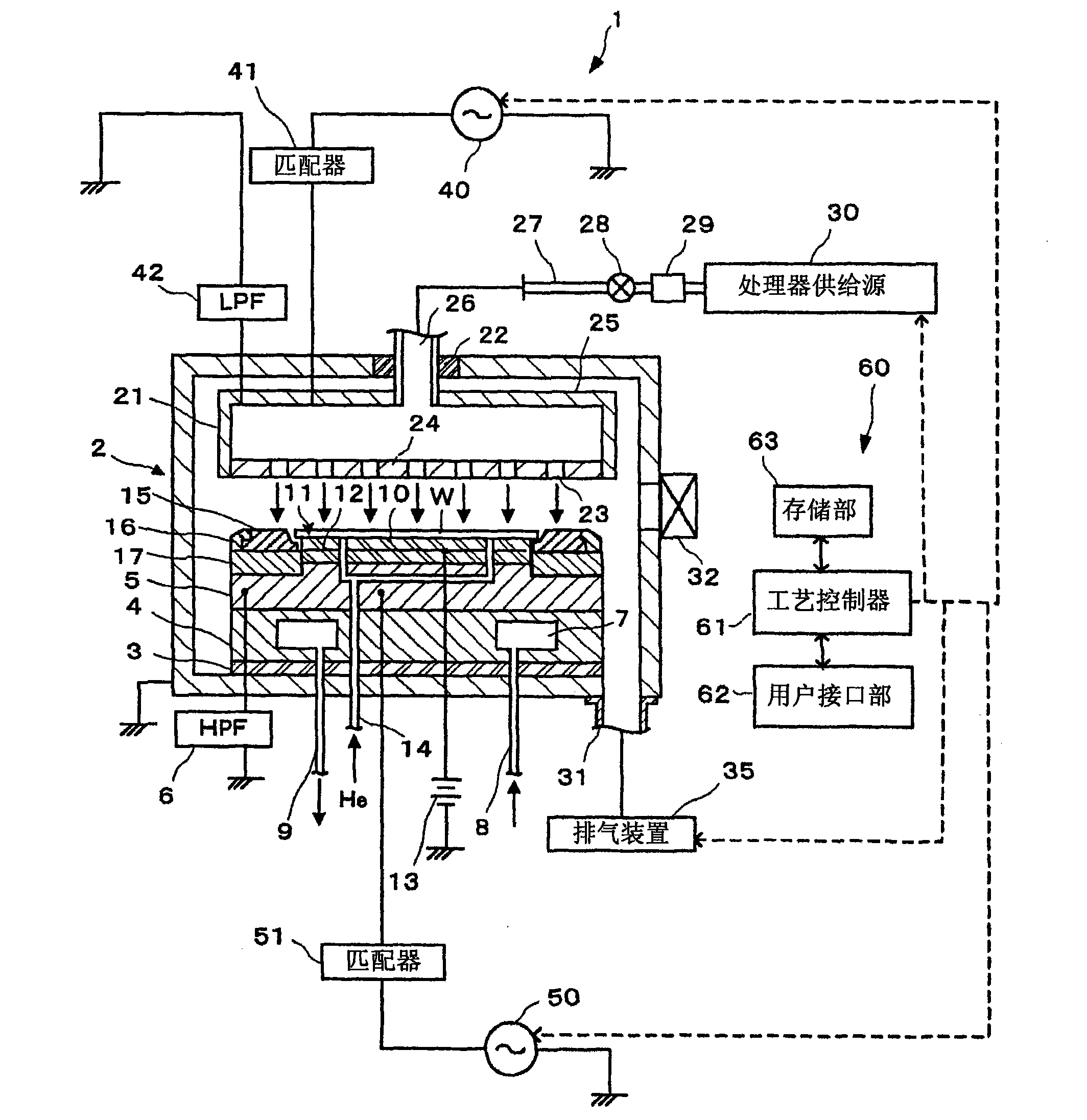

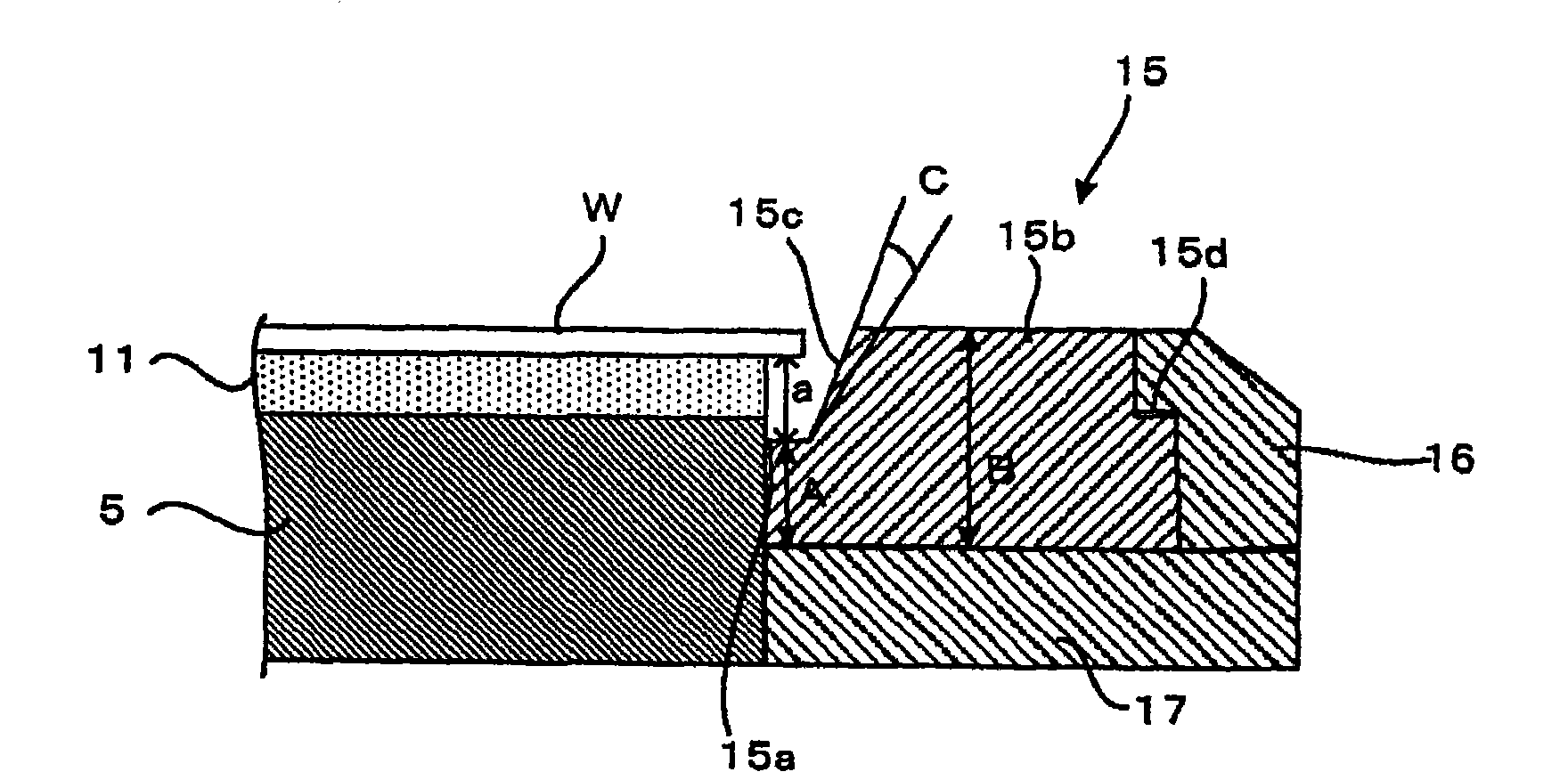

[0030] figure 1 It is a figure which shows the whole structure of the plasma etching apparatus 1 which is a real-time plasma processing apparatus of this invention, figure 2 It is a figure which shows the structure of the main part of the focus ring 15 and the plasma etching apparatus 1 concerning one embodiment of this invention. First, refer to figure 1 The overall structure of the plasma etching apparatus 1 will be described.

[0031] The plasma etching device 1 is configured as a capacitively coupled parallel plate etching device in which electrode plates face up and down in parallel, and a power source for plasma formation is connected.

[0032] The plasma etching apparatus 1 has a cylindrical processing chamber 2 formed of, for example, aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com