Light-redirecting article

A light redirection and product technology, which is applied in the direction of light guide, optics, optical components, etc., can solve the problem of difficult to obtain the overall manufacturing of small hemispherical lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] The following example shows that in one embodiment Figure 4A and 4B How each step is implemented given in:

[0113] 1. Substrate treatment. A thermal sensitive adhesive (TSA) material (Estane 5703; softening point 85° C.) was coated on a polyethylene terephthalate (PET) substrate to give a dry thickness of 7 μm. This was done by preparing an 8.3 wt% solution of Estane 5703 containing 1 wt% of fluorocarbon surfactant FC431 (based on the weight of Estane) from 3M Company in tetrahydrofuran (THF) and dissolving it at 101.6 cm 3 / m 2 The wet coverage is achieved by coating it on a 0.1mm thick polyethylene terephthalate (PET) sheet.

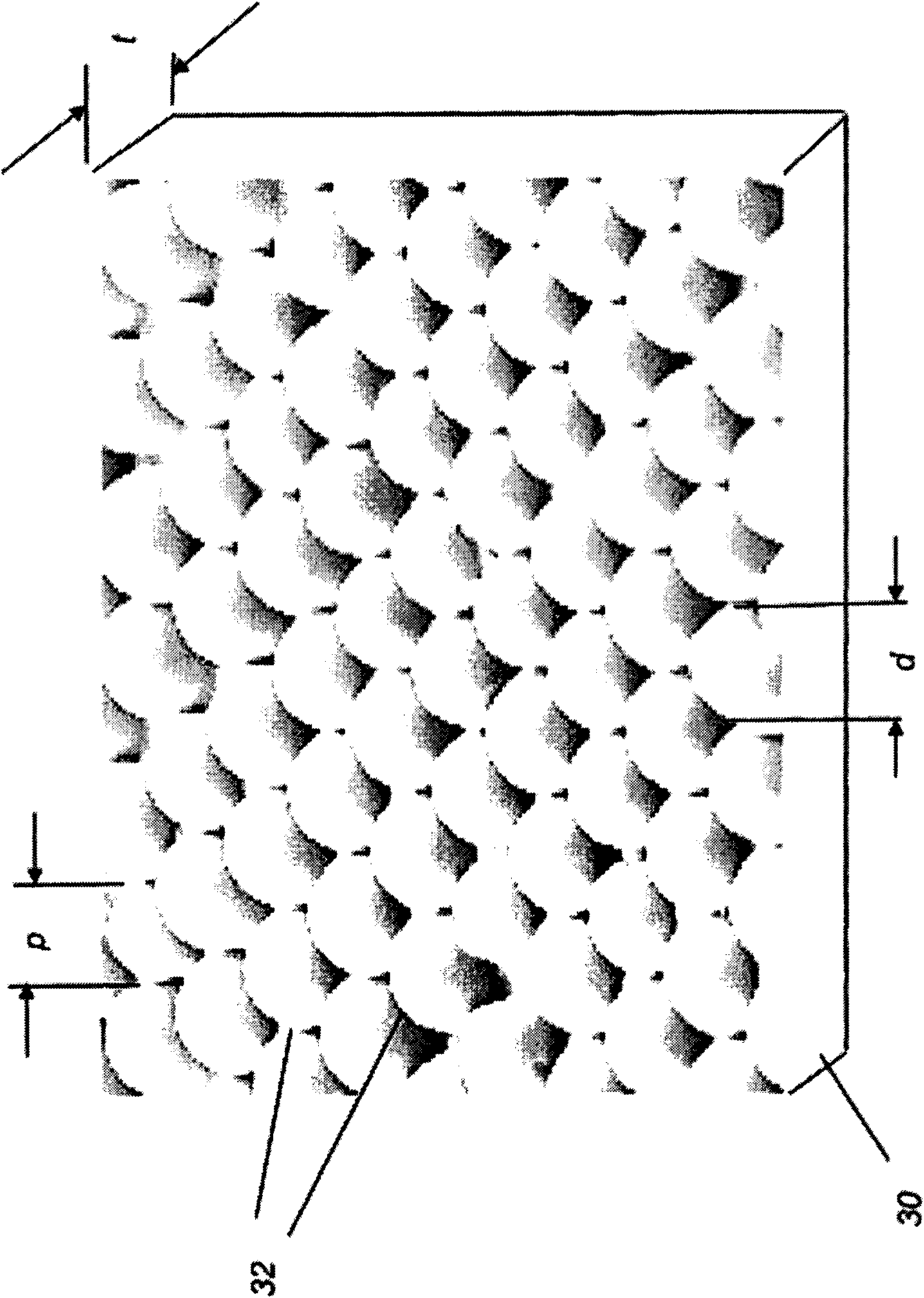

[0114] 2. Microsphere deposition and DASA self-accumulation. The water suspension containing 9.8wt% polystyrene microspheres (average diameter 3.4 μm, coefficient of variation (cv) 0.3), fish skin glue and Olin 10G surfactant was separated in 21.5cm 3 / m 2 of wet coverage applied to the TSA layer. The coating was then dried at 30°C to ...

Embodiment 2

[0121] The following are examples of steps in an alternative embodiment of the invention.

[0122] 1. Substrate treatment. A 20 μm thick TSA film containing low density polyethylene (LDPE) was extrusion coated onto a 100 μm thick PET substrate.

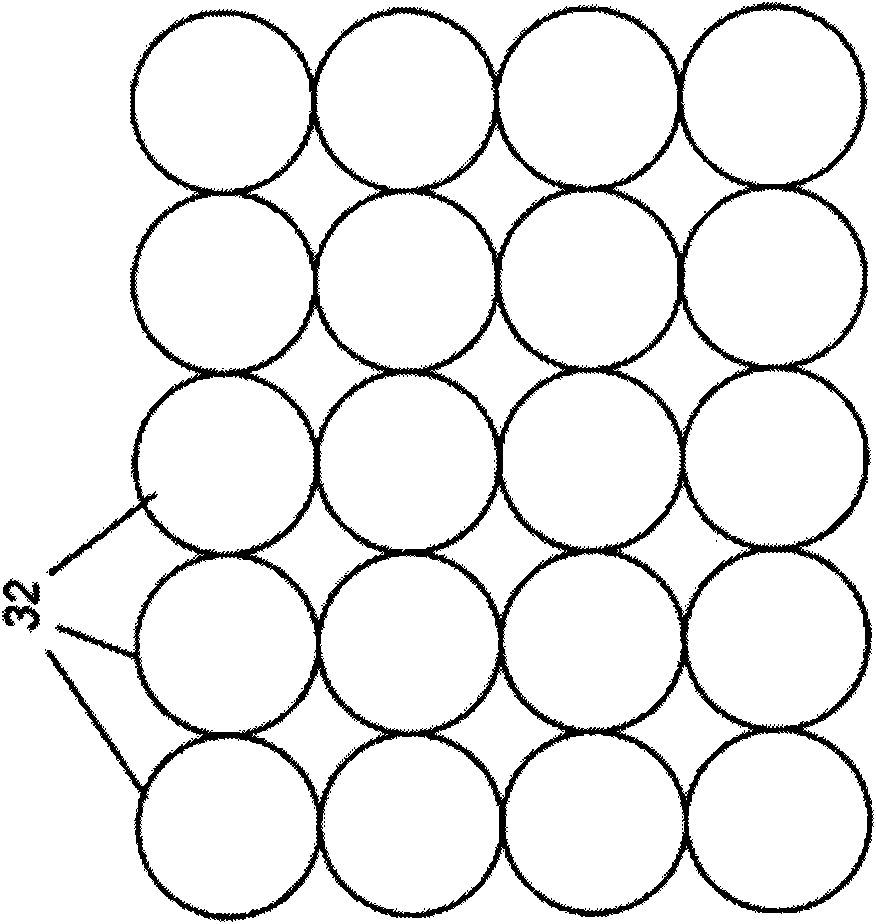

[0123] 2. Microsphere deposition and DASA self-accumulation. An aqueous suspension of poly(methyl methacrylate) (PMMA) microspheres (30 wt %) with an average size close to 10 μm and cv 2 The dry coverage of microspheres in an aqueous suspension containing 3% by weight of a polyalkylene oxide modified polydimethylsiloxane surfactant from Dow Corning. Examination of the coating by light microscopy revealed a mosaic monolayer containing 2D HCP domains.

[0124] 3. Embedding. To generate the close-packed micro-hemisphere arrays, the embedding of the microsphere close-packed arrays was accomplished by simply heating the assemblage in an oven set at 125°C for 2 minutes.

[0125] 4. Molding and curing. The coating with embedded microsph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com