Novel process for catalytic conversion of tetrachloromethane on non-hydrogen condition

A technology for catalyzing carbon tetrachloride and carbon tetrachloride, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve resource waste and use of tetrachloride Carbon and other issues to achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

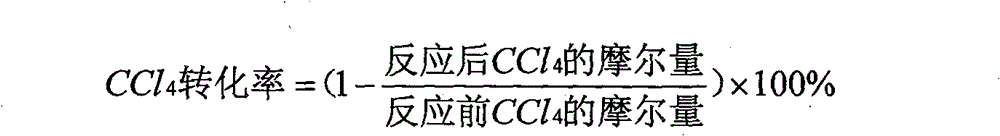

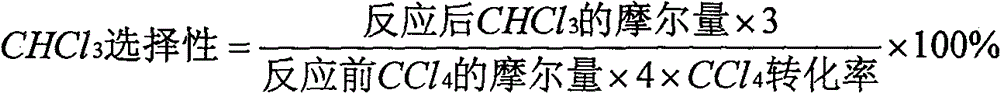

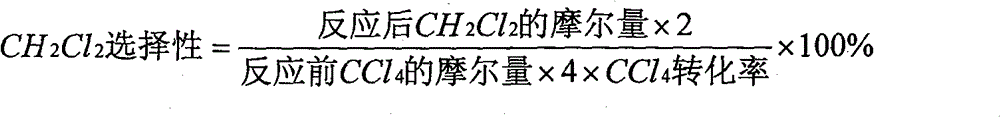

Method used

Image

Examples

Embodiment 1

[0021] Weigh the dried Al 2 o 3 3.00g, 2.63g nickel nitrate, dissolve nickel nitrate with 3.9g distilled water to make a solution, add nickel nitrate solution evenly to Al 2 o 3 In, soak for 24 hours. Then put it in air at 120°C for 5 hours, bake at 450°C for 3 hours under the protection of nitrogen, and reduce at 450°C for 3 hours in the presence of hydrogen. The prepared catalyst containing Ni mass percent is 15%, denoted as 15%Ni / Al 2 o 3 .

[0022] In a stainless steel autoclave, 0.3 g of the catalyst prepared above was added, 2 mL of carbon tetrachloride and 28 mL of methanol were added. Close the reactor, replace the air in the reactor with nitrogen for three times, then feed nitrogen and maintain the pressure in the reactor, heat up to 200°C, the reaction pressure is 4.0MPa, start stirring, react at constant temperature for 9 hours, and analyze the product with gas chromatography The results are shown in Table 1.

Embodiment 2

[0024] Weigh the dried SiO 2 4.00g, copper chloride 0.18g, fully dissolve copper chloride with 8.8g distilled water to form a solution, and add copper chloride solution evenly to SiO 2 In, soak for 24 hours. Then put it in the air to dry at 120°C for 5 hours, bake at 300°C for 2 hours under the protection of nitrogen, and reduce at 400°C for 3 hours in the presence of hydrogen. The prepared catalyst contains 2% by mass of Cu, denoted as 2%Cu / SiO 2 .

[0025] In a stainless steel autoclave, 0.8 g of the catalyst prepared above was added, 5 mL of carbon tetrachloride and 25 mL of methanol were added. Close the reactor, replace the air in the reactor with nitrogen for three times, then feed nitrogen and maintain the pressure in the reactor, raise the temperature to 150°C, the reaction pressure is 2.0MPa, start stirring, react at constant temperature for 9 hours, and analyze the product with gas chromatography The results are shown in Table 1.

Embodiment 3

[0027] Replace SiO in Example 2 with mesoporous carbon 2 , using the same catalyst preparation method as in Example 2, the prepared catalyst contains 2% by mass of Cu, which is denoted as 2%Cu / MC.

[0028] In a stainless steel autoclave, add 0.8 g of the catalyst prepared above, add 10 mL of carbon tetrachloride and 20 mL of methanol. Close the reactor, replace the air in the reactor with nitrogen for three times, then feed nitrogen and maintain the pressure in the reactor, heat up to 130°C, the reaction pressure is 2.0MPa, start stirring, react at constant temperature for 9 hours, and analyze the product with gas chromatography The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com