Mobile pulse jetting deashing device

A technology of pulse injection and dust cleaning device, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. It can solve the problems of equipment maintenance, inconvenient maintenance, expensive pulse valve, and increased equipment cost. Effects of detection, reduction in the number of use, and reduction in equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

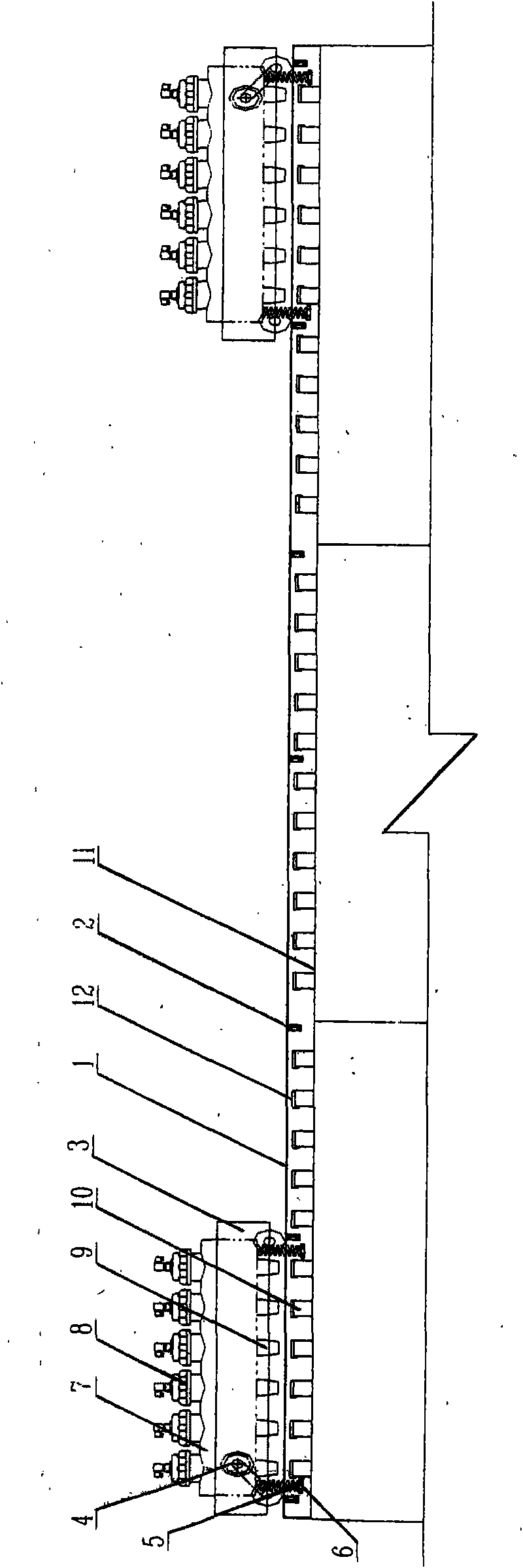

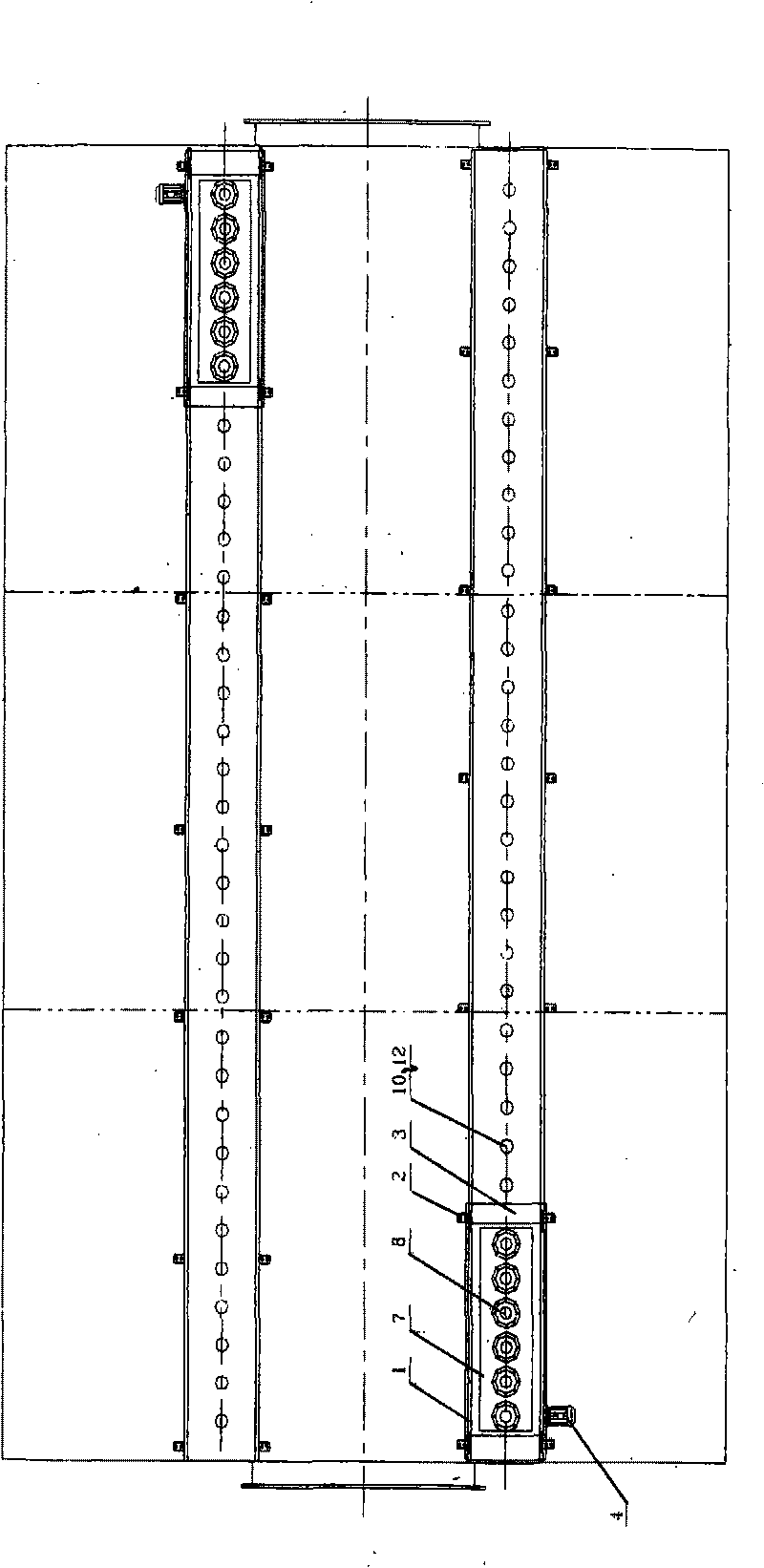

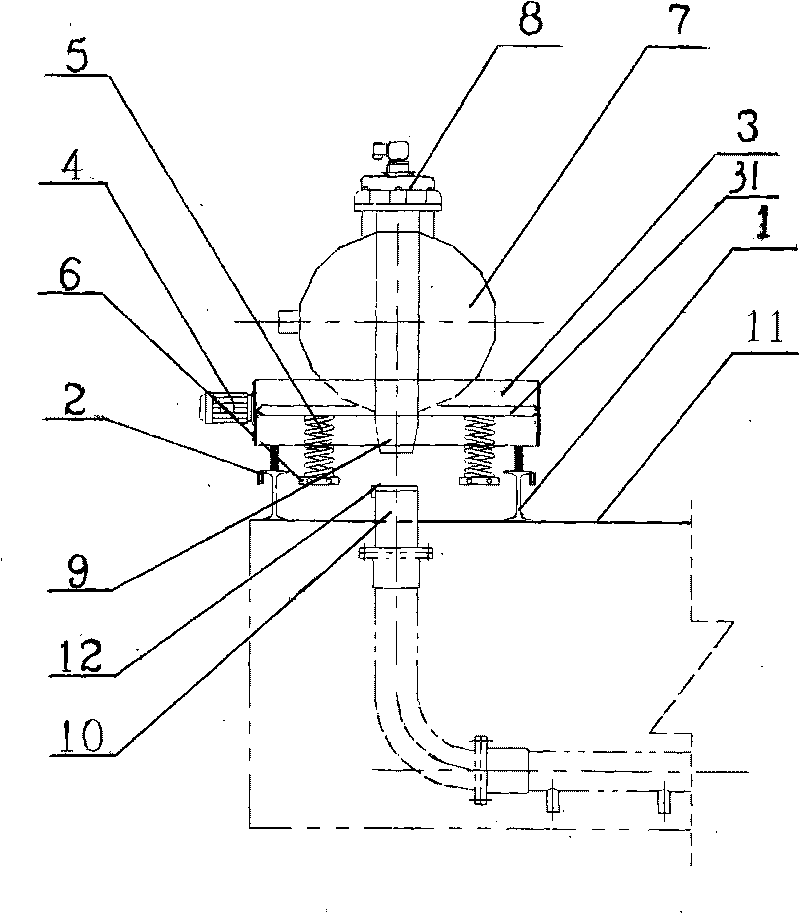

[0013] like figure 1 , 2 , As shown in 3, a mobile pulse jet dust removal device includes an air bag, a pulse valve and a short jet pipe. Two pairs of guide rails 1 are respectively fixed on the top cover 11 of the bag filter above the blowing pipe 10 of the bag house on both sides of the centerline of the air inlet and outlet of the bag filter, and each pair of guide rails is provided with a motor 4 driven Mobile trolley 3. The inside of the mobile trolley is provided with a vertical slide rail, and a support frame 31 is provided on the vertical slide rail, and an air bag 7 is fixed on the support frame, and the air bag is connected with two to six pulse valves 8 as a group. The blowing short pipe 9 passes through the bottom of the air bag, corresponding to the bag chamber blowing pipe extending on the top cover of the bag filter. A spring 5 is respectively fixed in the four corners of the bottom of the air bag support frame, and the lower end of the spring is fixed with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap