Machining method of rotating blade spacer of axial compressor/turbine

A processing method and a technology of a partition block, which are applied to the components of a pumping device for elastic fluids, machines/engines, mechanical equipment, etc. Waste of chuck materials and other problems, to achieve the effect of improving material utilization, reducing processing procedures, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1:

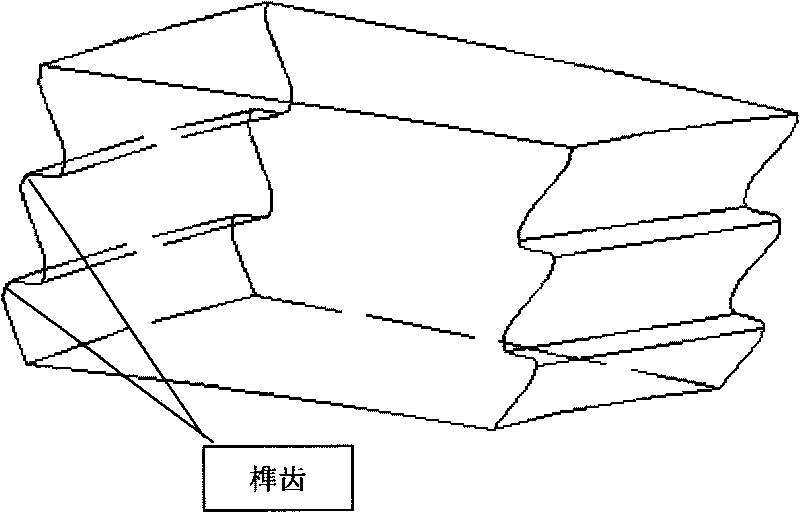

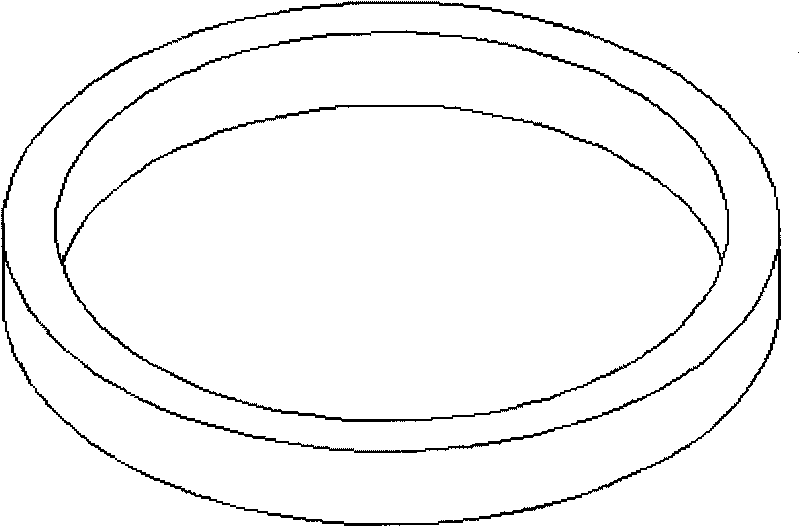

[0034] The outer circle of the moving vane partitions of the axial flow compressor AV80 series product 4xxx is the same as the outer diameter of the main shaft of the product, and the radius is 400mm. , the maximum thickness is 43.65mm, and it is installed in the tongue and groove with a width of 130mm on the main shaft. The baffle block is suitable for the locking structure of the moving blade with the shaft diameter of the axial compressor being 800mm and the moving blade specification being 125K. For the structure of the moving blade partition block, see figure 1 a, figure 1 b.

[0035] The conventional processing flow is single or multiple one-piece blanking → forging → heat treatment → milling → sawing → processing shape → CNC milling machine processing tenon teeth → vertical turning processing of outer arc → inspection and storage.

[0036] The concrete implementation steps of adopting the partition block processed by the present invention are as ...

Example Embodiment

[0047] Example 2:

[0048] The outer circle of the moving vane blocks used in the axial flow compressor AV56 series product 4xxx is the same as the outer diameter of the main shaft of the product, and the radius is 280mm. , the maximum thickness is 33.39mm, and it is installed in the tongue and groove with a width of 83mm on the main shaft. The baffle block is suitable for the locking structure of the moving blade with the diameter of the main shaft of the axial compressor being 560mm and the specification of the moving blade being 80K. For the structure of the moving blade partition block, see figure 1 a, figure 1 b

[0049] The conventional processing flow is single or multiple one-piece blanking → forging → heat treatment → milling → sawing → processing shape → CNC milling machine processing tenon teeth → vertical turning processing of outer arc → inspection and storage.

[0050] The concrete implementation steps of adopting the partition block processed by the present ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap