Labyrinth seal type bearing cap of enamelling machine

A labyrinth seal and bearing cap technology, applied in the mechanical field, can solve problems such as easy water ingress, poor bearing sealing, and water cannot be discharged, and achieve good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0009] The present invention will be further described below with reference to the specific drawings and embodiments.

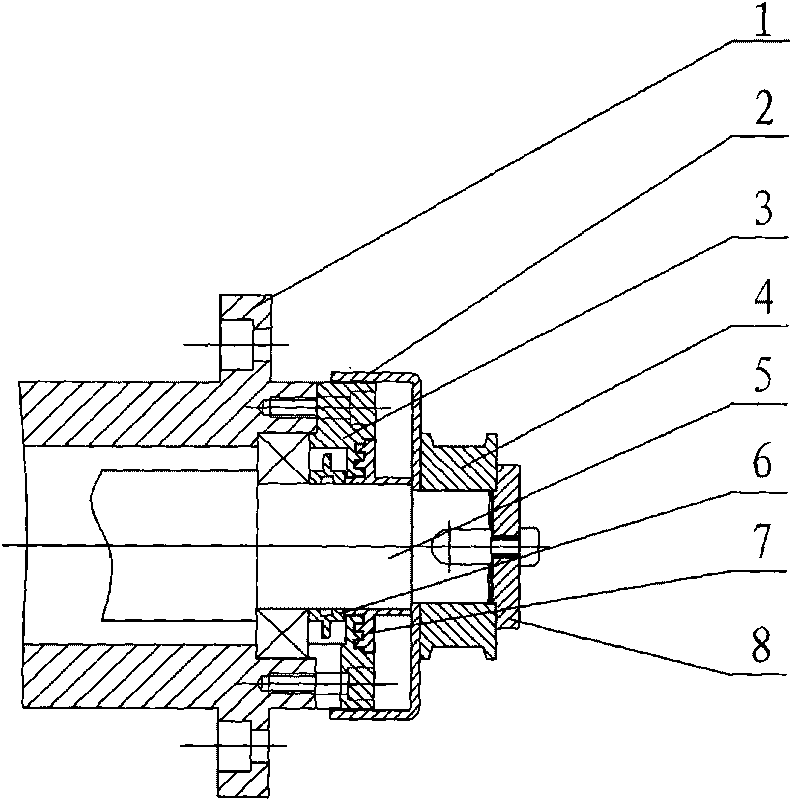

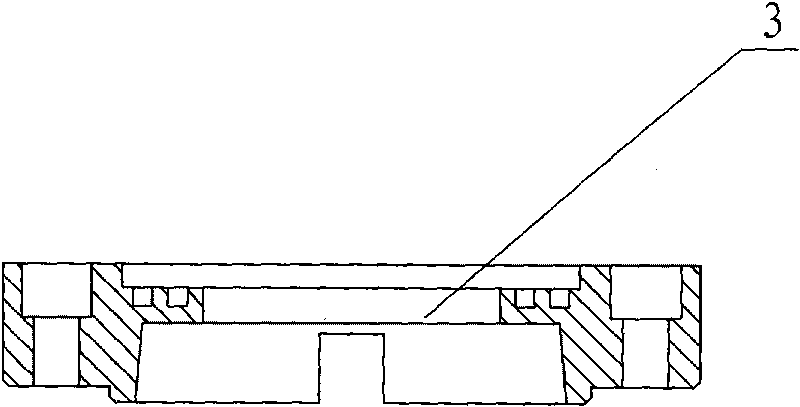

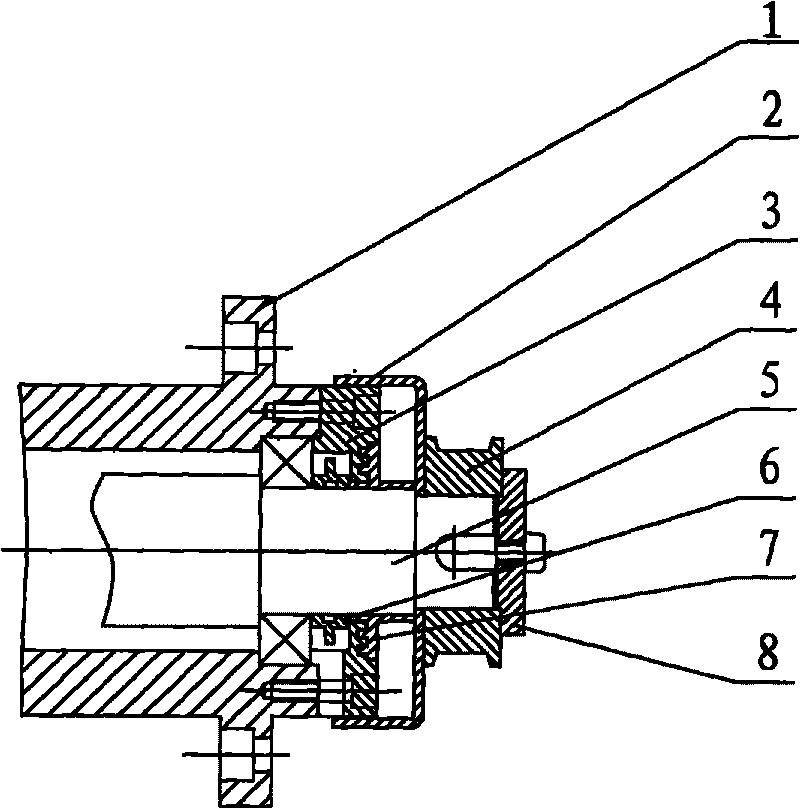

[0010] like Figures 1 to 2 Shown: the bearing cover includes a bearing seat 1, a waterproof cover 2, a bearing end cover 3, a drawing hub wheel 4, a drawing shaft 5, a water throwing disc 6, a labyrinth bearing 7, an end cover 8, etc.

[0011] In the present invention, a bearing seat 1 is arranged on the outer surface of the wire drawing shaft 5, and a bearing end cover 3 is arranged at one end of the bearing seat 1. The bearing end cover 3 is sealed by a labyrinth bearing 7, and a groove is opened on the lower side of the bearing end cover 3 , a water throwing disc 6 is sleeved around the wire drawing shaft 5 inside the bearing end cover 3, and a waterproof cover 2 is provided on the outer cover of the bearing end cover 3, and the edge of the waterproof cover 2 is provided with a waterproof enclosure. A wire drawing hub 4 is arranged on the wire drawing sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap