Functional group grafted porous membrane compound perfluorinated ion exchange membrane

A perfluorinated ion and ion exchange technology, applied in the direction of semi-permeable membrane separation, membrane technology, fuel cell parts, etc., can solve the problems of membrane strength reduction, fuel cell impact, gas permeability increase, etc., and achieve high mechanical strength Effects of properties and airtightness, excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

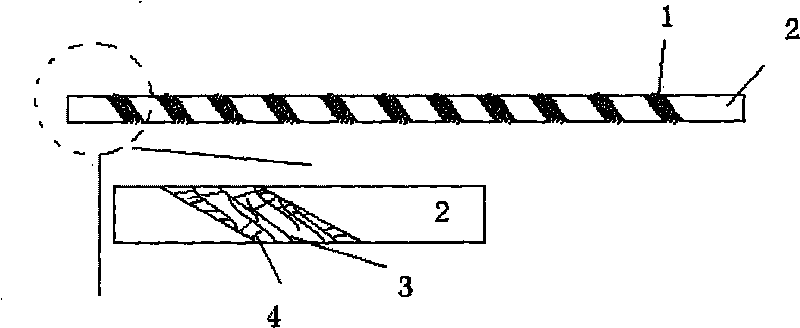

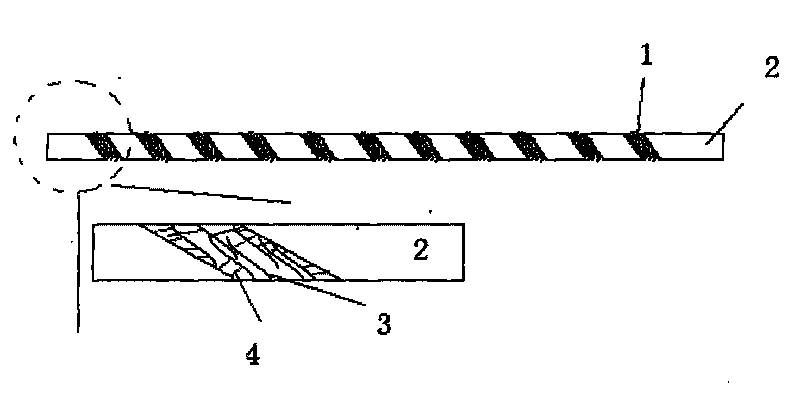

[0052] Example 1

[0053] Take 15 micron quilt

[0054]

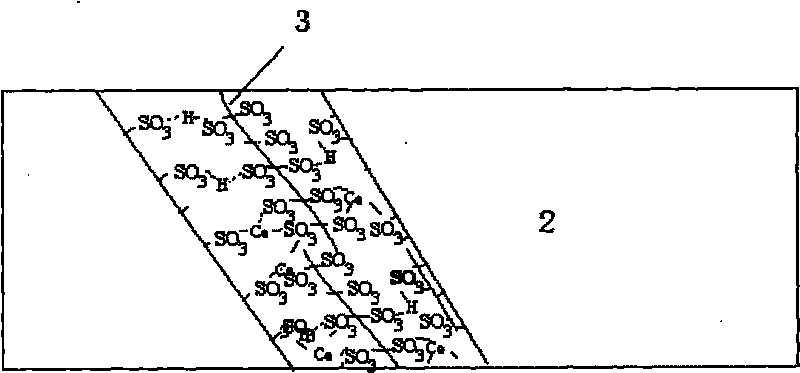

[0055] Where h=0, i=2 A=OH

[0056] The grafted polytetrafluoroethylene membrane (porosity 80%, pore diameter 1 micron), first immersed in a solution of cerium (III) nitrate, and then immersed in 25% perfluorosulfonic acid resin ethanol-water solution, perfluorinated The structural formula of the sulfonic acid resin is (IV), n=1, p=2, the ion exchange capacity is 0.97 mmol / g, and the molecular weight is 200,000.

[0057] Then, the wet film was treated at 190°C for 20 minutes to obtain a composite film with a thickness of 16 microns.

Example Embodiment

[0058] Example 2

[0059] The molecular formula of perfluorosulfonic acid resin is (IV), n=0, p=2, ion exchange capacity is 1.35mmol / g, molecular weight is 210,000, 15% perfluorosulfonic acid resin in propanol-water solution is sprayed on a 10 micron blanket

[0060]

[0061] Where h=0, i=4 A=ONa

[0062] The grafted polytetrafluoroethylene-hexafluoropropylene membrane (porosity 85%, pore size 0.5 micron), the grafted polytetrafluoroethylene-hexafluoropropylene membrane is first immersed in a solution of manganese (II) nitrate. . Then, the wet film sample was dried in an oven at 140°C for 30 seconds. In order to completely occlude the pores in the membrane, this process step can be repeated more than 2 times. Finally, the composite membrane was treated at 1500°C for 30 minutes to obtain a composite membrane with a thickness of 20 microns.

Example Embodiment

[0063] Example 3

[0064] The structural formula of perfluorosulfonic acid resin is (IV), n=0, p=4, ion exchange capacity is 1.25mmol / g, molecular weight is 190000, and 10% isopropanol-propanol-water solution of perfluorosulfonic acid resin is prepared.

[0065] 10 micron quilt

[0066]

[0067] Where h=1, i=2 A=F

[0068] The grafted polytetrafluoroethylene membrane (porosity 90%, pore size 2-3 microns), hydrolyzed with 10% NaOH, 100°C, and soaked in the La(III)-DMF complex solution. The grafted polytetrafluoroethylene film modified with a high-valent metal and a 10% perfluorosulfonic acid resin isopropanol-propanol-water solution were screen-printed to obtain a composite film with a thickness of 11 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap