Manual multi-knife lens cutter

A cutting machine and lens technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of many scratches on the glass surface, low output accuracy, and low production efficiency, and achieve high blank size accuracy, The effect of high cutting efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0010] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

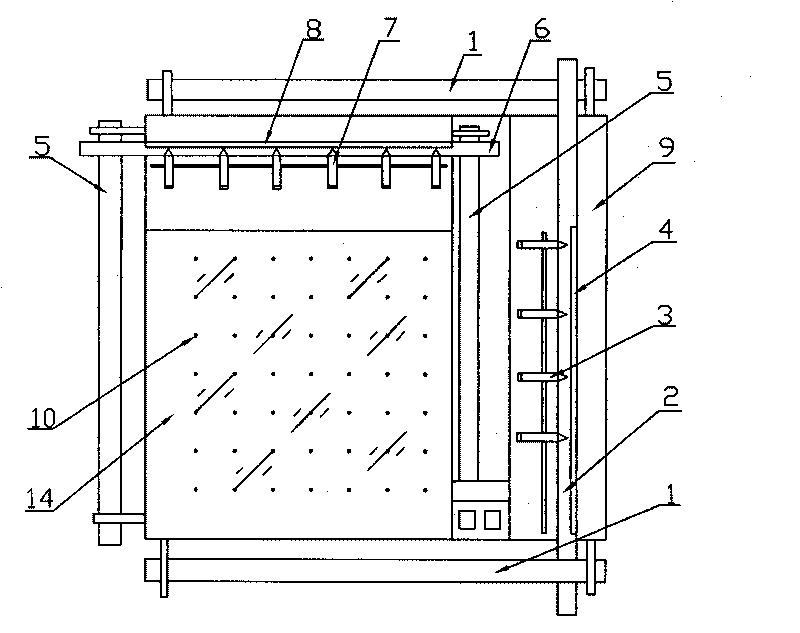

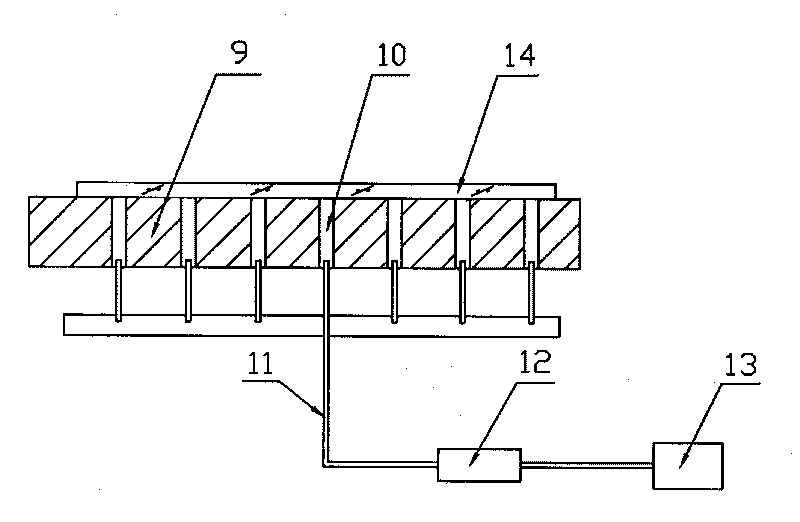

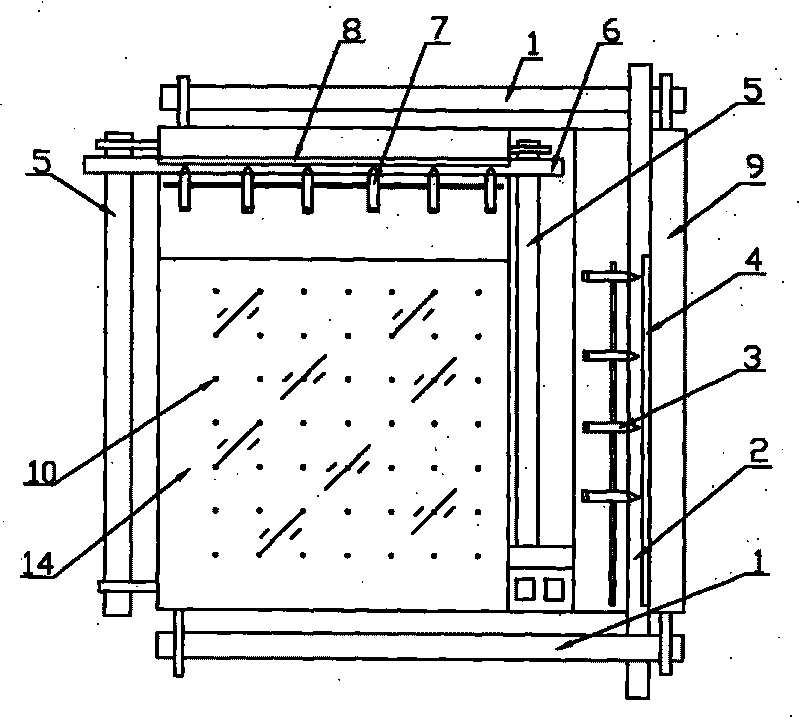

[0011] A manual multi-knife lens cutting machine, such as figure 1 , figure 2 As shown, it includes a transverse guide rail 1, a transverse knife rest 2, a transverse cutting knife 3, a transverse scale 4, a longitudinal guide rail 5, a longitudinal knife rest 6, a longitudinal cutting knife 7, a longitudinal scale 8, a workbench 9, an air suction hole 10, Suction pipe 11, foot-operated air valve 12 and frame, workbench 9 are fixed on the frame, two transverse guide rails 1 are fixedly installed on the top and bottom of workbench 9 respectively, and are distributed in parallel, and transverse tool rest 2 Set on two transverse guide rails 1, the transverse knife rest 2 is perpendicular to the transverse guide rail 1, the transverse cutting knives 3 are installed on the transverse knife rest 2 at equal intervals, and the transverse scale 4 is fixed on the tran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap