Method for preparing powder oxygen-containing graphene and powder of oxygen-containing grapheme/tetrapolyaniline

A technology of graphene powder and graphene, applied in the field of preparation of supercapacitor electrode materials, can solve the problem of low capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of Tetraaniline: Add 80 gram of sodium chloride and 0.8 gram of N-phenyl-1,4-phenylenediamine to 400 milliliters of 1 mole per liter of hydrochloric acid, add 12 milliliters of hydrogen peroxide (mass fraction 30% ) After the reaction, tetrapolyaniline powder is obtained.

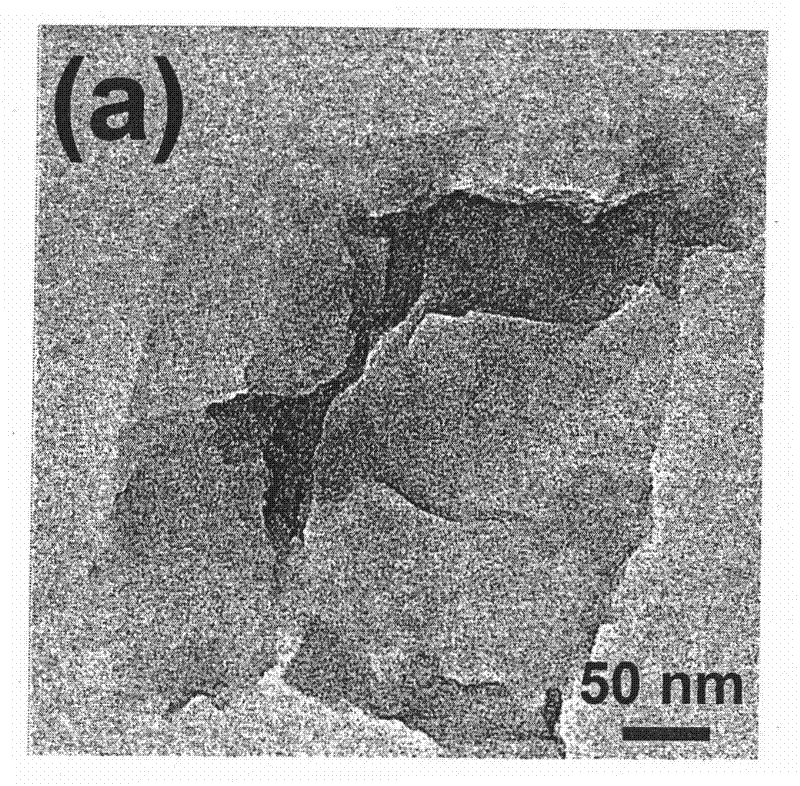

[0017] Add 0.1 gram of graphite oxide into 100 milliliters of water, and ultrasonically disperse it for 2 hours to form a graphene oxide colloid whose mass concentration is 1 mg / ml uniformly dispersed in a monolithic layer; 3 milliliters of hydrobromic acid is added to the resulting graphene oxide colloid, Pour into a three-neck round-bottomed flask equipped with a condenser tube, an electric stirrer and a glass stopper, boil and reflux at an oil bath temperature of 110° C. and stir for 24 hours to obtain a black oxygen-containing graphene colloid. Filter the obtained black oxygen-containing graphene colloid, wash with ethanol and water, and dry to obtain the oxygen-containing graphene po...

Embodiment 2

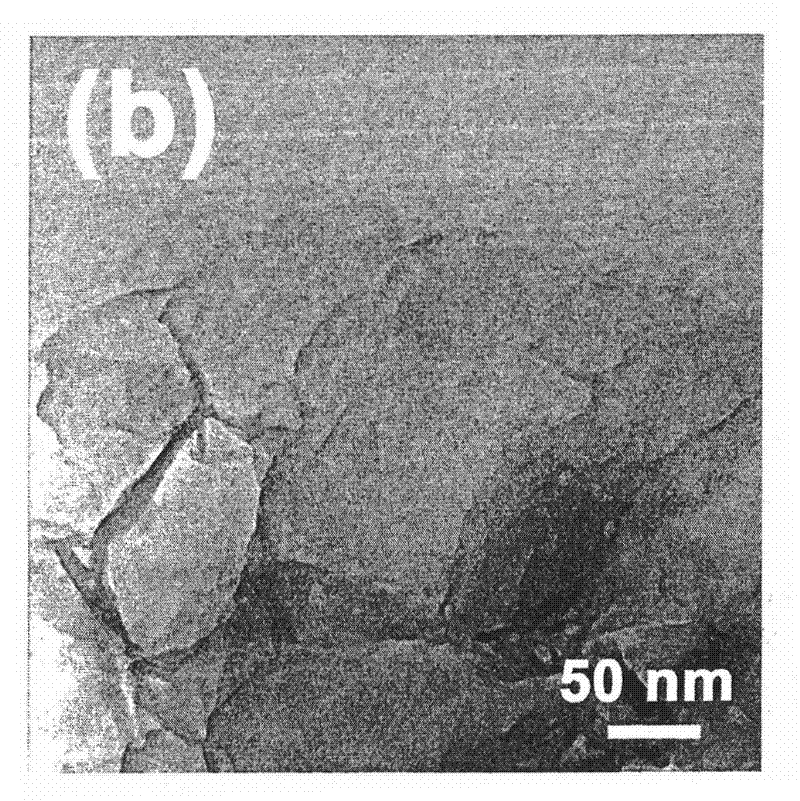

[0021] Add 0.1 gram of graphite oxide into 200 milliliters of water, and ultrasonically disperse for 2 hours to form a uniformly dispersed graphene oxide colloid with a mass concentration of 0.5 mg / ml; add 3 milliliters of hydrobromic acid to the resulting graphene oxide colloid , poured into a three-neck round-bottomed flask equipped with a condenser, an electric stirrer and a glass stopper, boiled and refluxed at an oil bath temperature of 110°C and stirred for 24 hours to obtain a black oxygen-containing graphene colloid. Filter the obtained black oxygen-containing graphene colloid, wash with ethanol and water, and dry to obtain the oxygen-containing graphene powder;

[0022] Add 0.1 gram of graphite oxide into 200 milliliters of water, and ultrasonically disperse for 2 hours to form a graphene oxide colloid with a mass concentration of 0.5 mg / ml uniformly dispersed in a single layer; dissolve 0.1 gram of tetraaniline in 100 milliliters of N, N- Methylformamide, made into t...

Embodiment 3

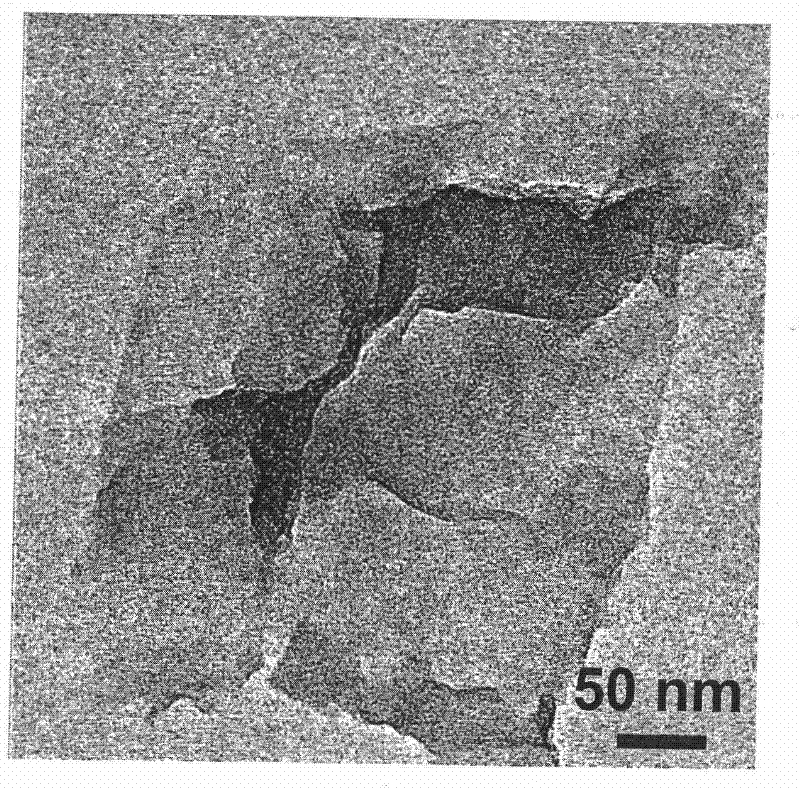

[0024] Add 0.1 gram of graphite oxide into 150 milliliters of water, and ultrasonically disperse for 2 hours to form a uniformly dispersed graphene oxide colloid with a mass concentration of 0.67 mg / ml; add 3 milliliters of hydrobromic acid to the resulting graphene oxide colloid , poured into a three-neck round-bottomed flask equipped with a condenser, an electric stirrer and a glass stopper, boiled and refluxed at an oil bath temperature of 110°C and stirred for 24 hours to obtain a black oxygen-containing graphene colloid. Filter the obtained black oxygen-containing graphene colloid, wash with ethanol and water, and dry to obtain the oxygen-containing graphene powder;

[0025] Add 0.1 gram of graphite oxide into 150 milliliters of water, and ultrasonically disperse for 2 hours to form a single-layer uniformly dispersed graphene oxide colloid with a mass concentration of 0.67 mg / ml; dissolve 0.1 gram of tetraaniline in 100 milliliters of N, N-di Methylformamide, made into te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com