LPG heating back blowing regenerative diesel engine particulate trap device

A particle capture, diesel engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of limitation, trouble, excessive diesel sulfur content, etc., and achieve the effect of improving toughness and capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

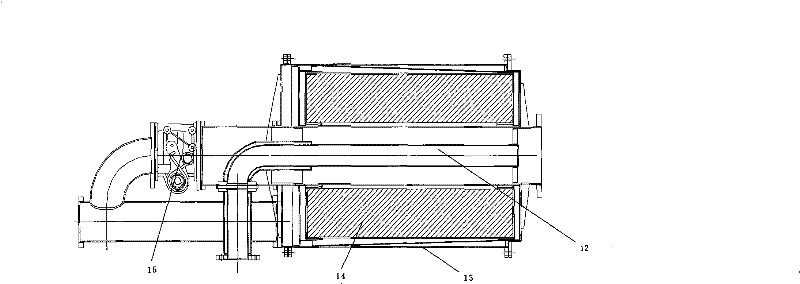

[0011] In order to verify the feasibility of the invention, the engine bench test and the actual bus operation test have been carried out successively. figure 2 For the Particle Precipitation Device (DPF), the device is installed at the rear of the bus in place of the original muffler. Close the 15 bypass valve and the heating interface. At this time, the exhaust gas discharged from the engine reaches the inside of the DPF device and then flows through 13 high-density cylindrical wire meshes and then flows out. The wire mesh traps the black smoke in the exhaust gas. 13. The mesh number of the cylindrical wire mesh gradually increases from the inside to the outside. When a certain amount is trapped, the pressure sensor measures the increase in the exhaust back pressure. Regeneration occurs when a predetermined value is reached.

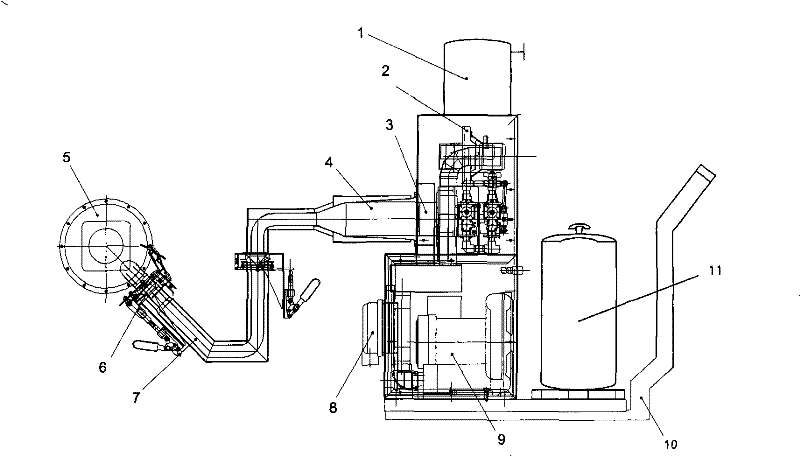

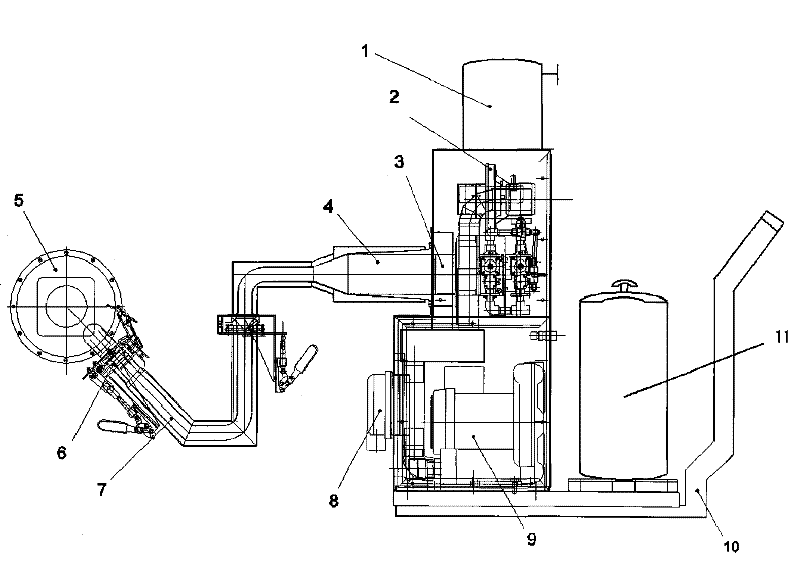

[0012] When regenerating, the figure 1 The regeneration unit shown is connected to the DPF unit. Open the heating interface, and use 6 clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com