Method for producing feedstocks of high quality lube base oil from coking gas oil

A technology for coking gas oil and lubricating base oil, applied in lubricating compositions, hydrocarbon oil treatment products, hydrocarbon oil treatment, etc., can solve problems that have not yet been considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

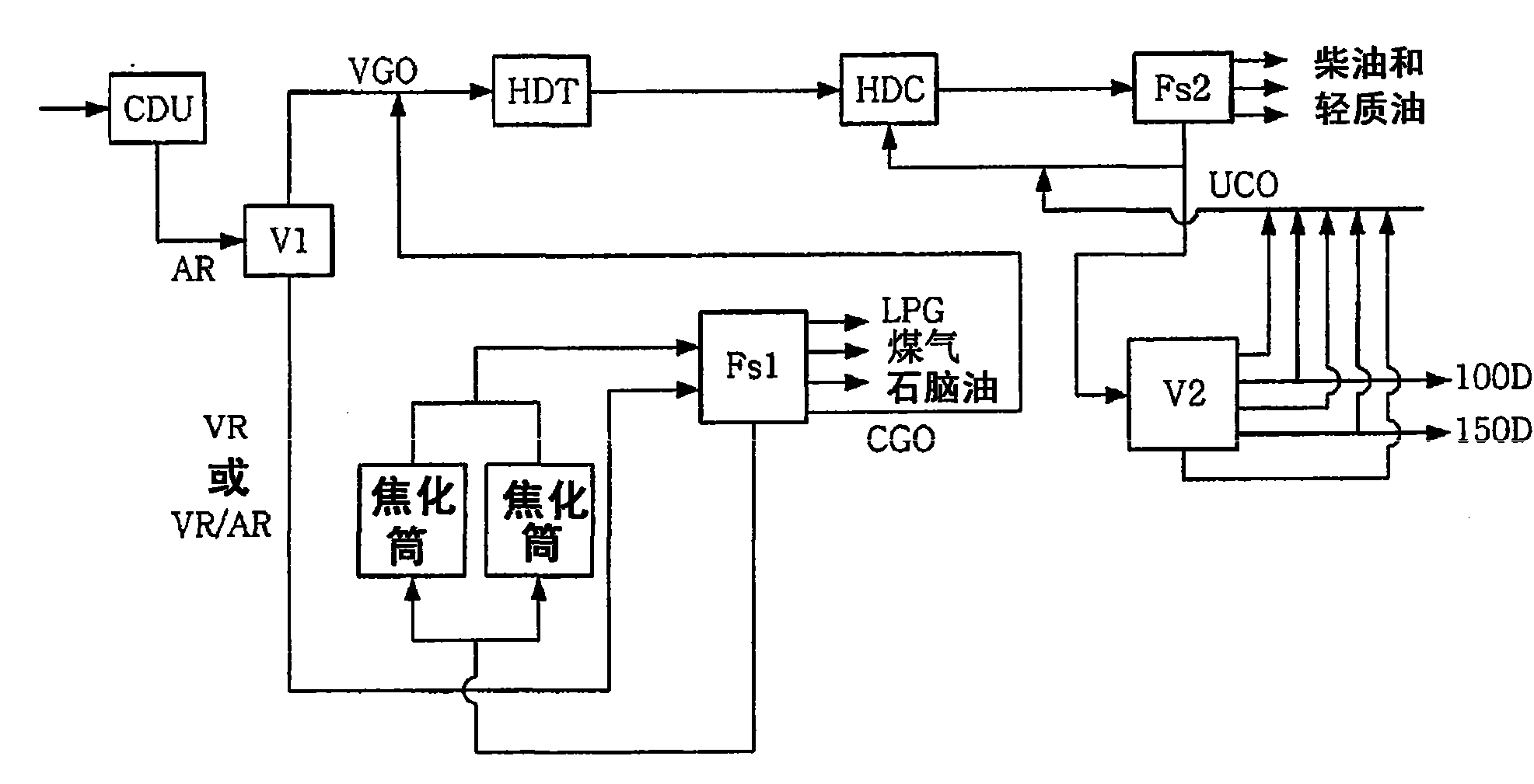

Method used

Image

Examples

Embodiment 1

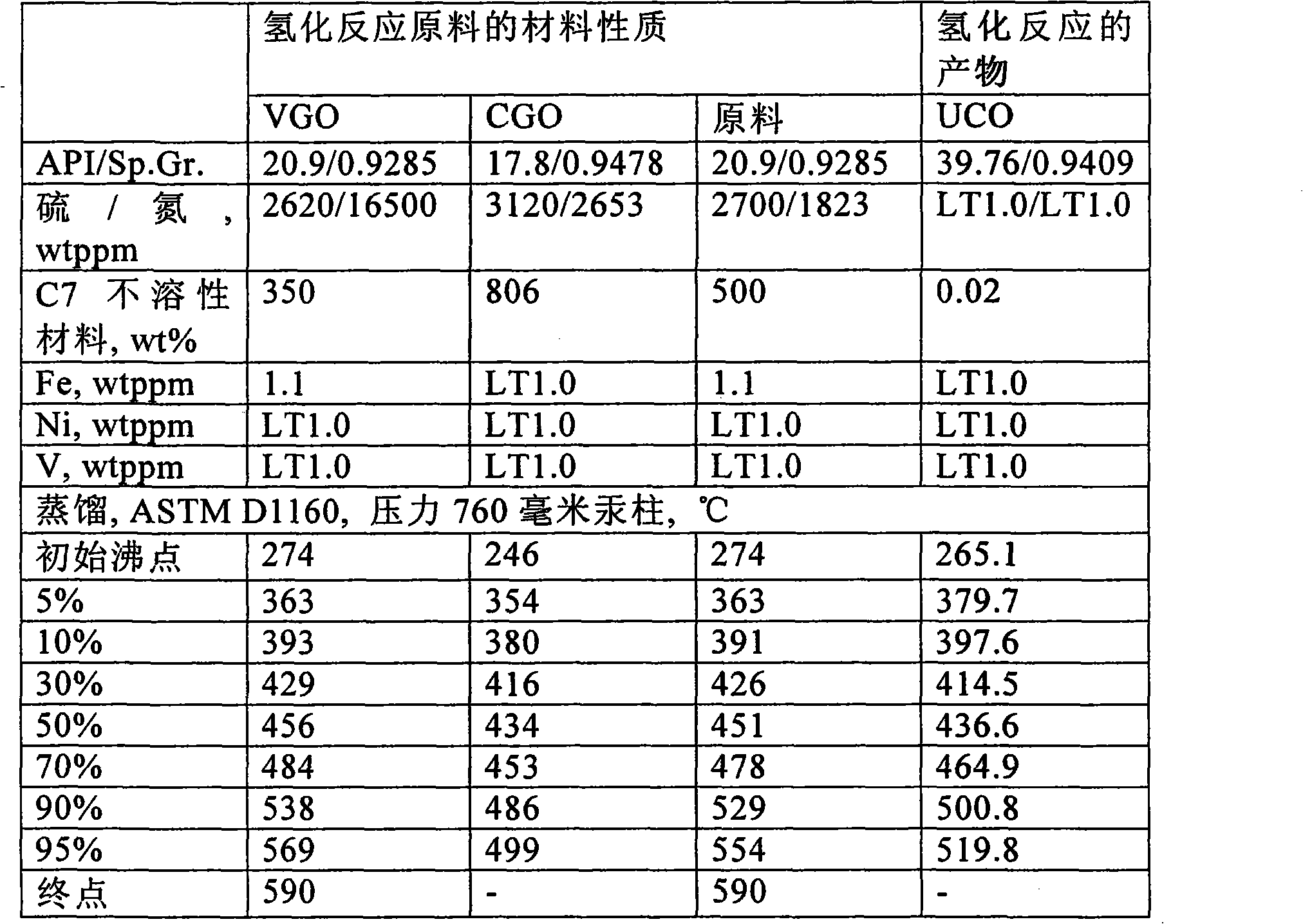

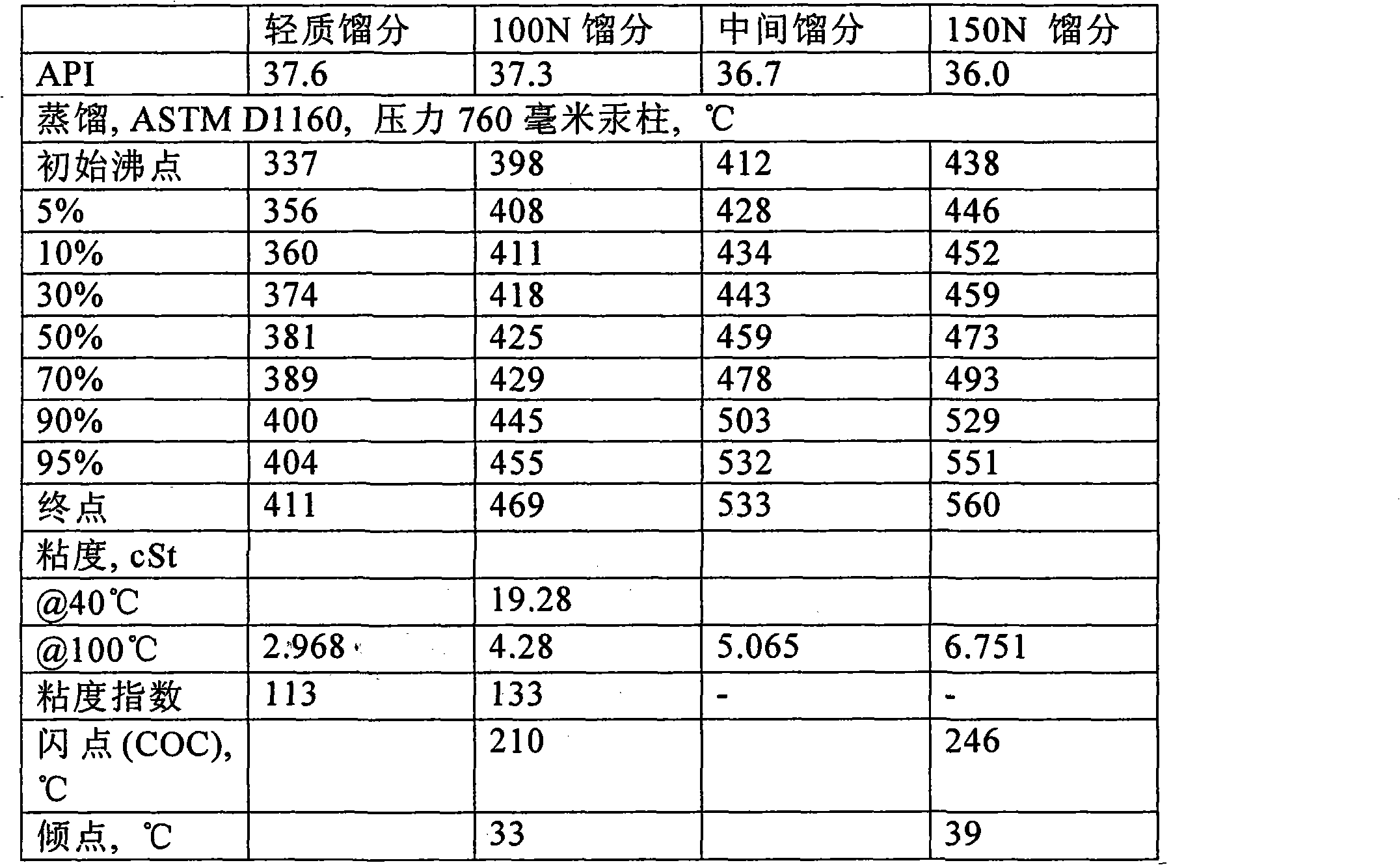

[0043] The low boiling point components are separated from the vacuum residue (VR), which is separated from the atmospheric residue (Ar) by the first vacuum distillation unit (V1), the first fractionation unit (Fs1), and then the vacuum residue (VR) heated to 500°C and then introduced into the coking drum. Then the vacuum residue (VR) is heated to 550°C in the coking drum, and the pressure at the upper end of the coking drum is 25Psig, so that the remaining liquid in the coking drum is converted into coke and light hydrocarbon gas, which is separated by the first fractionation device (Fs1) The light hydrocarbon gases are separated into LPG, coal gas, naphtha, and coker gas oil (CGO). Coker gas oil (CGO) and vacuum diesel oil (VGO) having the material properties shown in Table 2 were processed in a hydrotreater (HDT) using a catalyst (UF-210STARS, produced by UOP Corporation) under the following conditions: LHSV (liquid hourly space velocity) is 3.429 hours -1 , the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com