Using method of liquid flame retardant

A liquid flame retardant and flame retardant technology, which is applied in the field of liquid flame retardants, can solve the problems of high cost, high viscosity, and low environmental protection level of solid flame retardants, so as to improve production efficiency, save costs, and achieve environmental protection and fire resistance effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

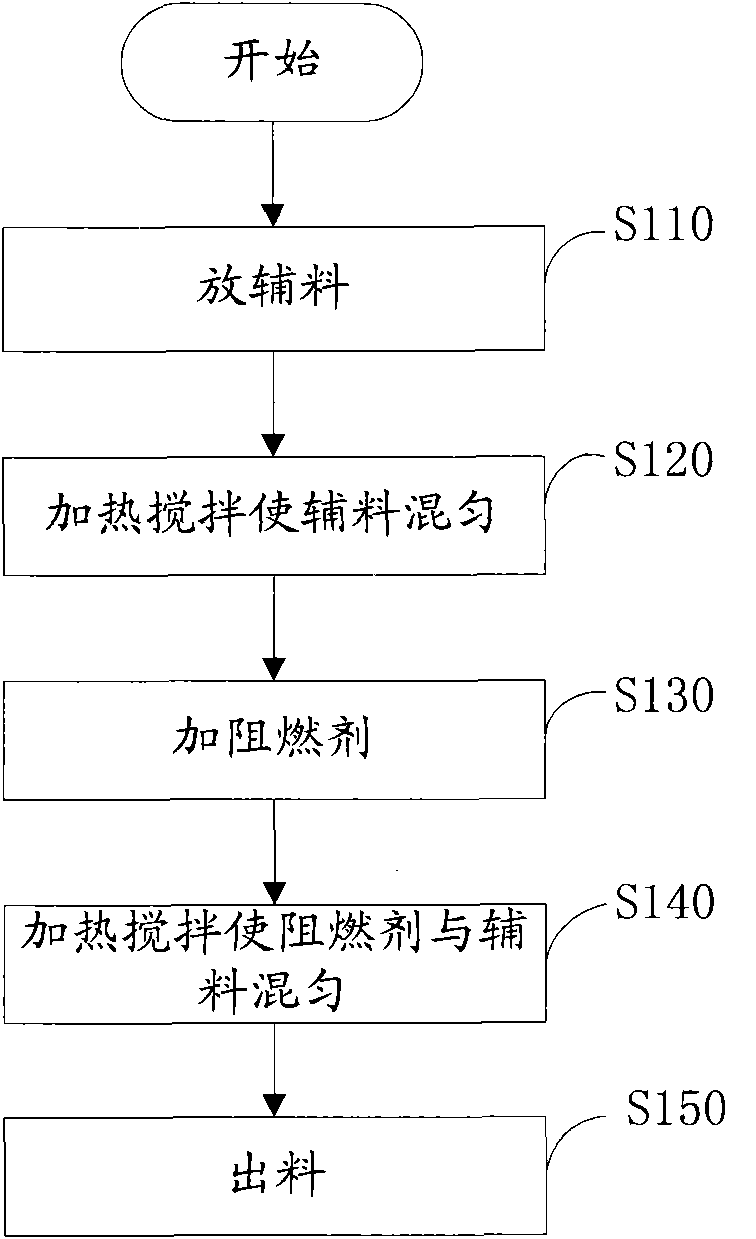

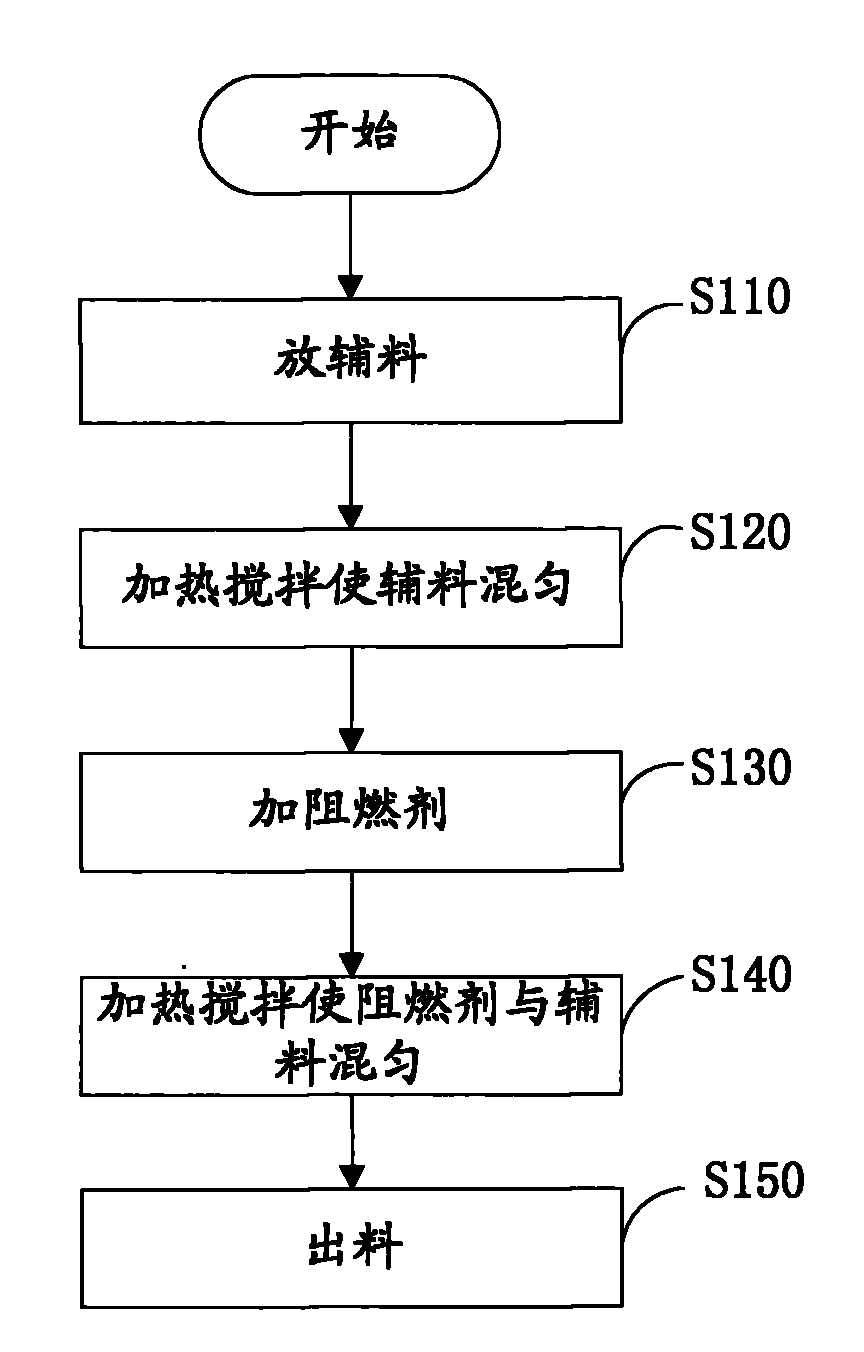

[0012] Such as figure 1 Shown is the flow chart of the method of using the liquid flame retardant, and the specific steps are as follows:

[0013] S110: put auxiliary materials.

[0014] S120: heating and stirring to mix the auxiliary materials evenly.

[0015] Put a certain volume of PC (Polycarbonate, polycarbonate), ABS (Acrylonitrile Butadiene Styrene, acrylonitrile-butadiene-propylene copolymer) and other auxiliary materials into the heating stirrer, and stir and heat, if the temperature is too high , PC and ABS will volatilize and decompose, and waste electric energy at the same time; the temperature is too low, the mixing efficiency is not high, and the mixing time is long. Generally, the heating and stirring temperature is within 50-100 ° C. At this time, PC, ABS, etc. can be well mixed.

[0016] S130: add liquid flame retardant.

[0017] The liquid flame retardants used here are halogen-free liquid flame retardants, mainly condensed non-halogen organic phosphorus f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com