Wet etching stripping method of SiC-substrate GaN-based LED

A wet etching and substrate technology, which is applied in the field of optoelectronics, can solve the problems of low reliability and low power, and achieve the effect of improving light extraction efficiency, significant effect and brightness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

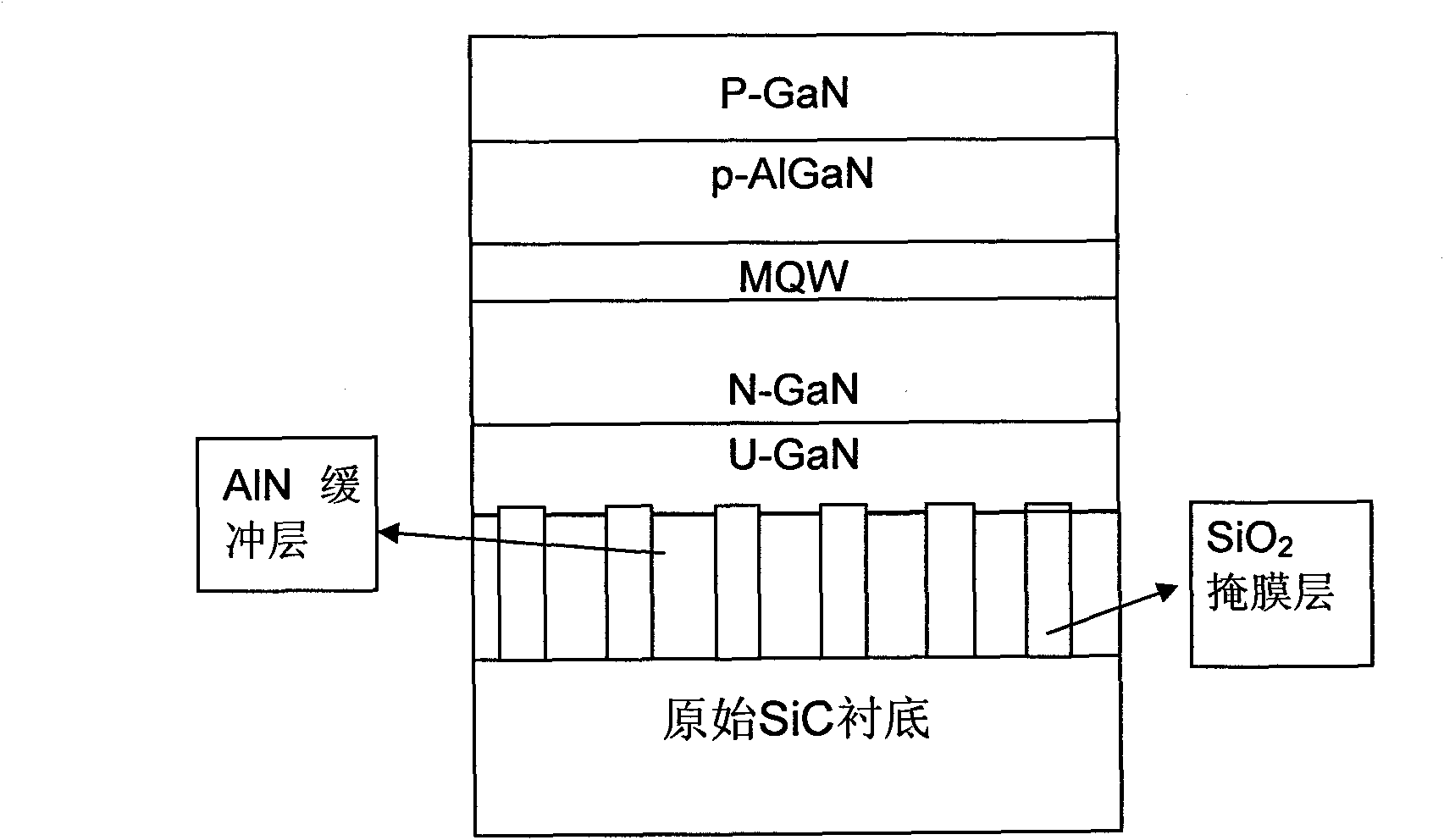

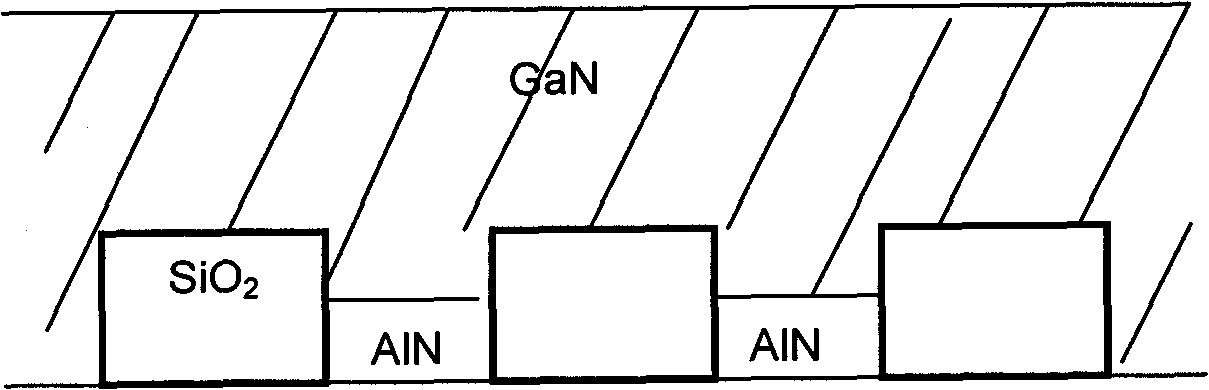

[0024]The wet etching and stripping manufacturing method of SiC substrate GaN-based LED of the present invention comprises the following three parts of the manufacturing process:

[0025] 1. Make the original SiC substrate pattern

[0026] (1) Put the original SiC substrate (different from ordinary sapphire substrate) into PECVD (plasma enhanced chemical vapor deposition) equipment, and evaporate a layer thickness of 1000 -3000 SiO 2 mask;

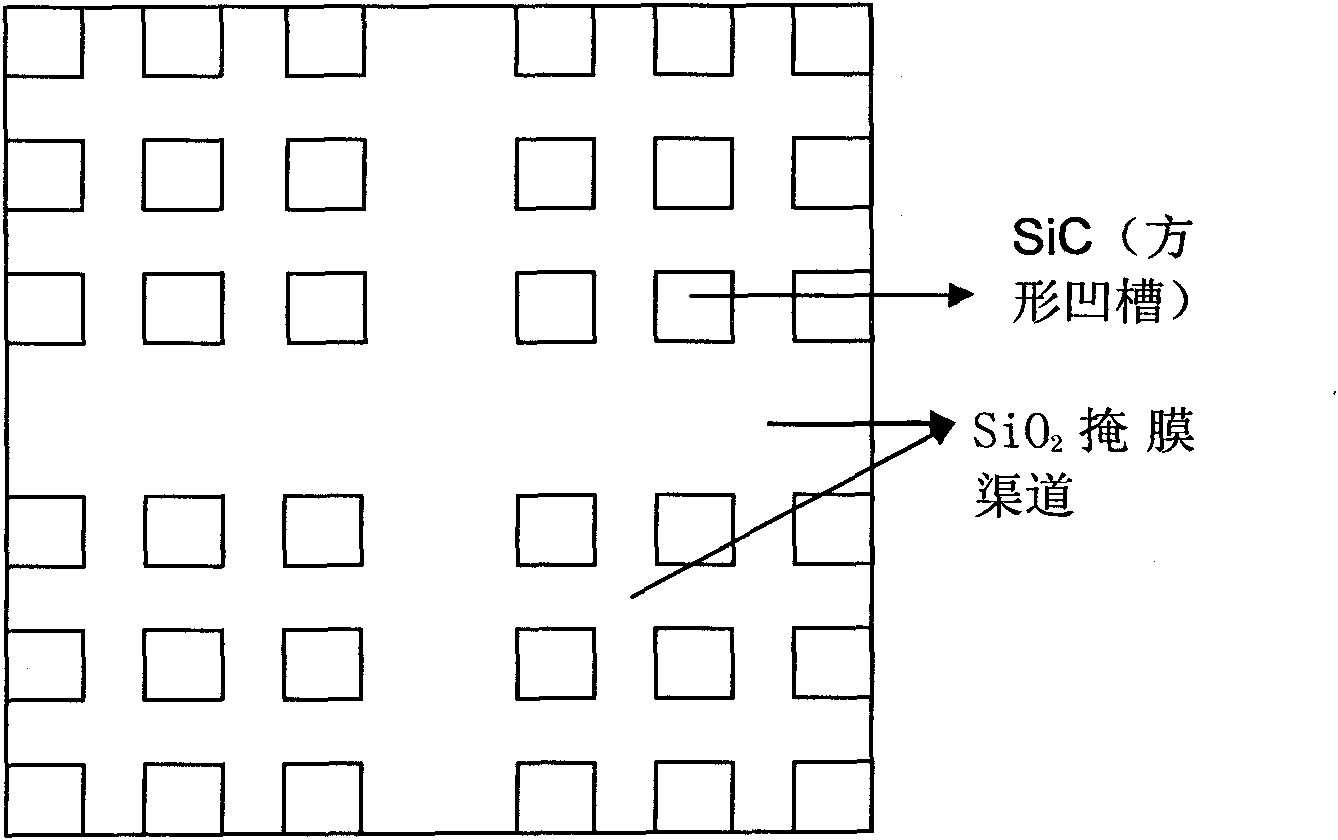

[0027] (2) Take out the evaporated SiO 2 After masking the original SiC substrate, the SiO 2 Coat photoresist on the mask, use the pre-engraved pattern mask on the SiO 2 On the mask, use a photolithography machine to carve the designed SiO that can form criss-cross patterns. 2 Graphics of the mask channel;

[0028] (3) developing;

[0029] (4) After development, use HF acid to etch away the SiO without photoresist 2 Mask, so that these parts expose the original SiC substrate surface, get figure 1 The square grooves shown are on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap