Miniature heating pressurizer for experiments

A supercharging device and technology for testing, which is applied in the field of small-scale heated supercharging devices for testing, can solve the problems of being unable to be widely used in laboratories, inconvenient preparation of small samples, and bulky equipment, and achieves simple structure, easy assembly, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

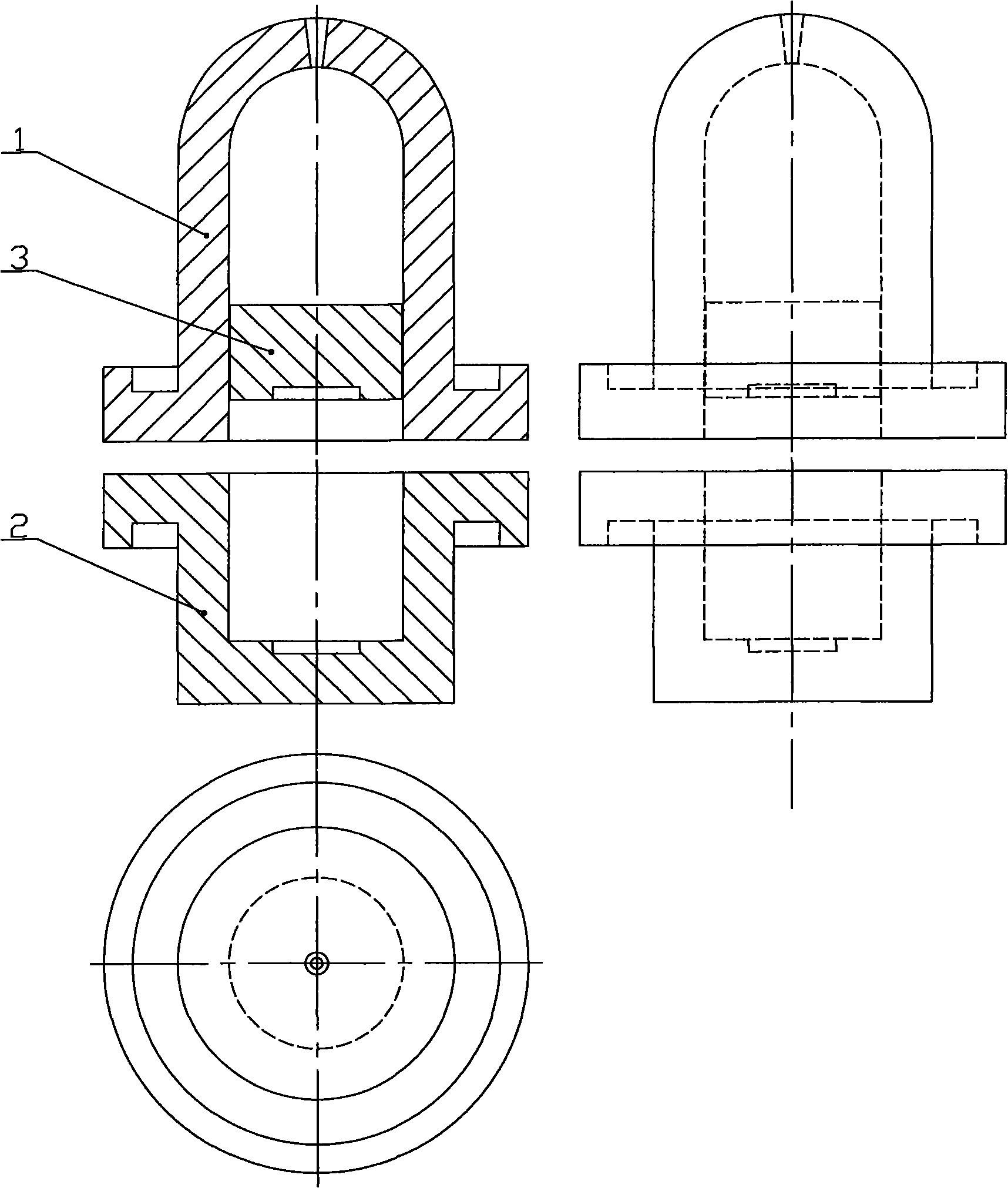

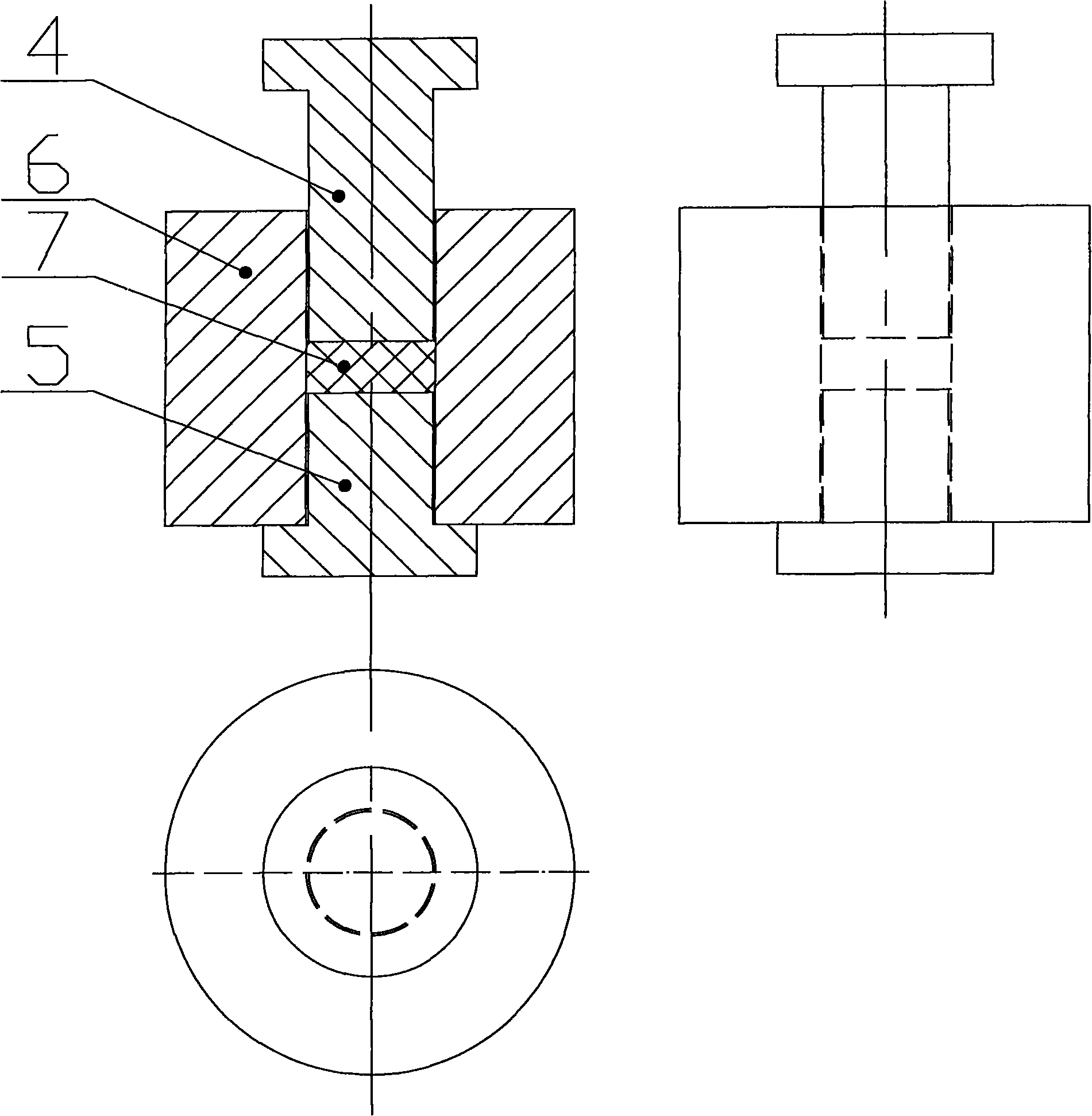

[0029] A kind of test of the present invention is used small-scale heated supercharging device, see figure 1 , figure 2 and Figure 4

[0030] figure 1 The radial cross-sections of the upper part 1 of the outer mold and the lower part 2 of the outer mold shown are all annular; wherein there is a vent hole on the top of the upper part 1 of the outer mold, and a vent valve with an overpressure protection function is installed; the outer mold The inside of the upper part 1 contains a closely fitting slider 3, which can reciprocate along the axial direction of the outer mold; after the upper part 1 of the outer mold and the lower part 2 of the outer mold are closed, they can be clamped firmly along the grooves on the outer periphery of the outer mold .

[0031] During implementation, the small sample raw material is first processed into a small disc whose size matches the inner mold, and placed between the inner mold upper pressing rod 4 and the inner mold lower pressing rod ...

Embodiment 2

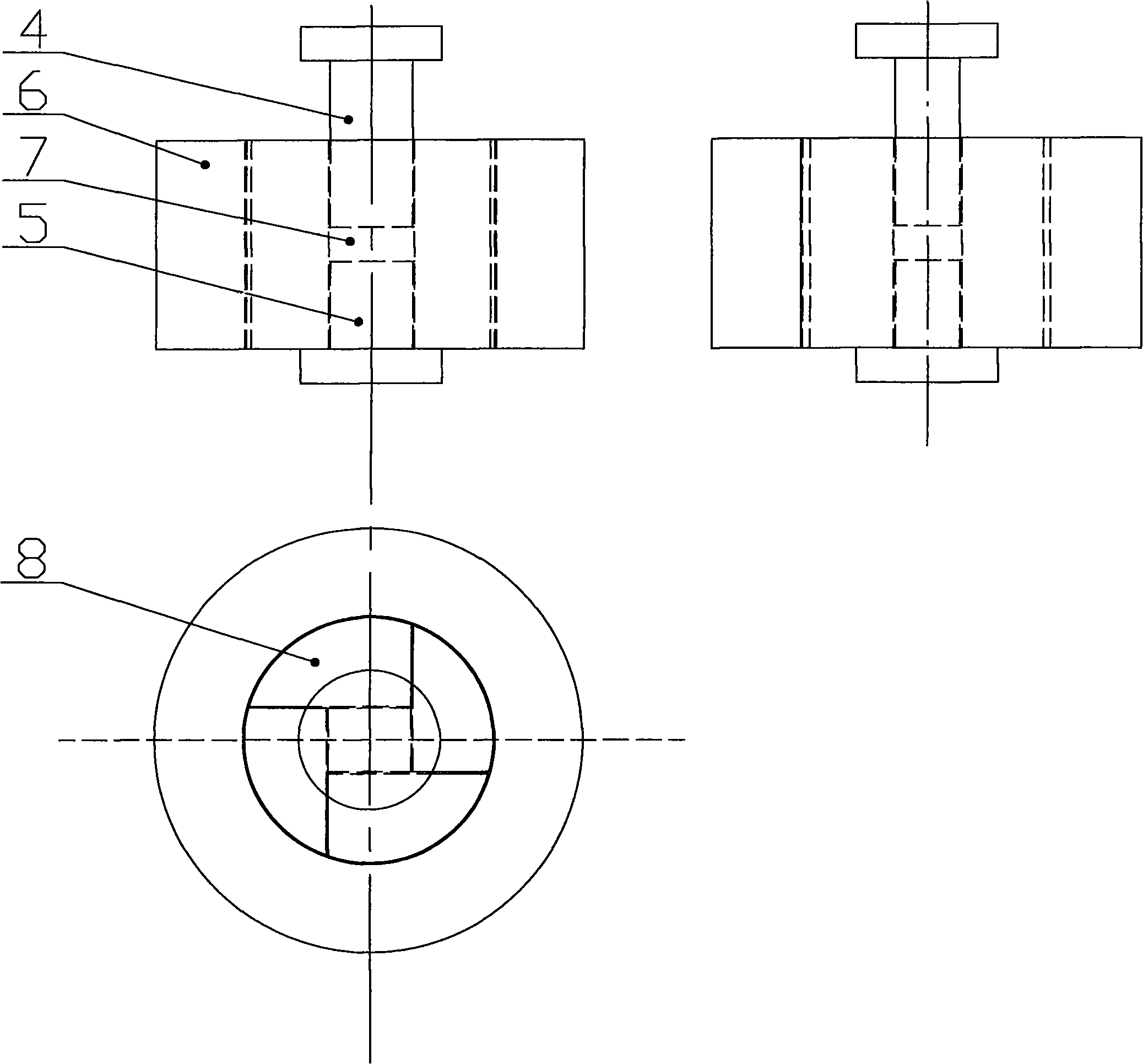

[0034] If the small sample raw material is processed into a small square 7, it can be used image 3 In the method shown, the small-scale sample raw material is placed between the two square-shaped pressure rods of the upper pressure rod 4 and the lower pressure rod 5 of the inner mold, tightly filled into the transformation module 8, and then placed in the round hole mold sleeve 6, form a whole, see image 3 . Other with embodiment 1, get final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com