Fixed component

A technology for fixing components and fixing frames, which is applied in the directions of printing, printing devices, etc., can solve the problems of inconvenient installation of the box structure, and achieve the effects of good consistency, avoidance of damage, and moderate strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

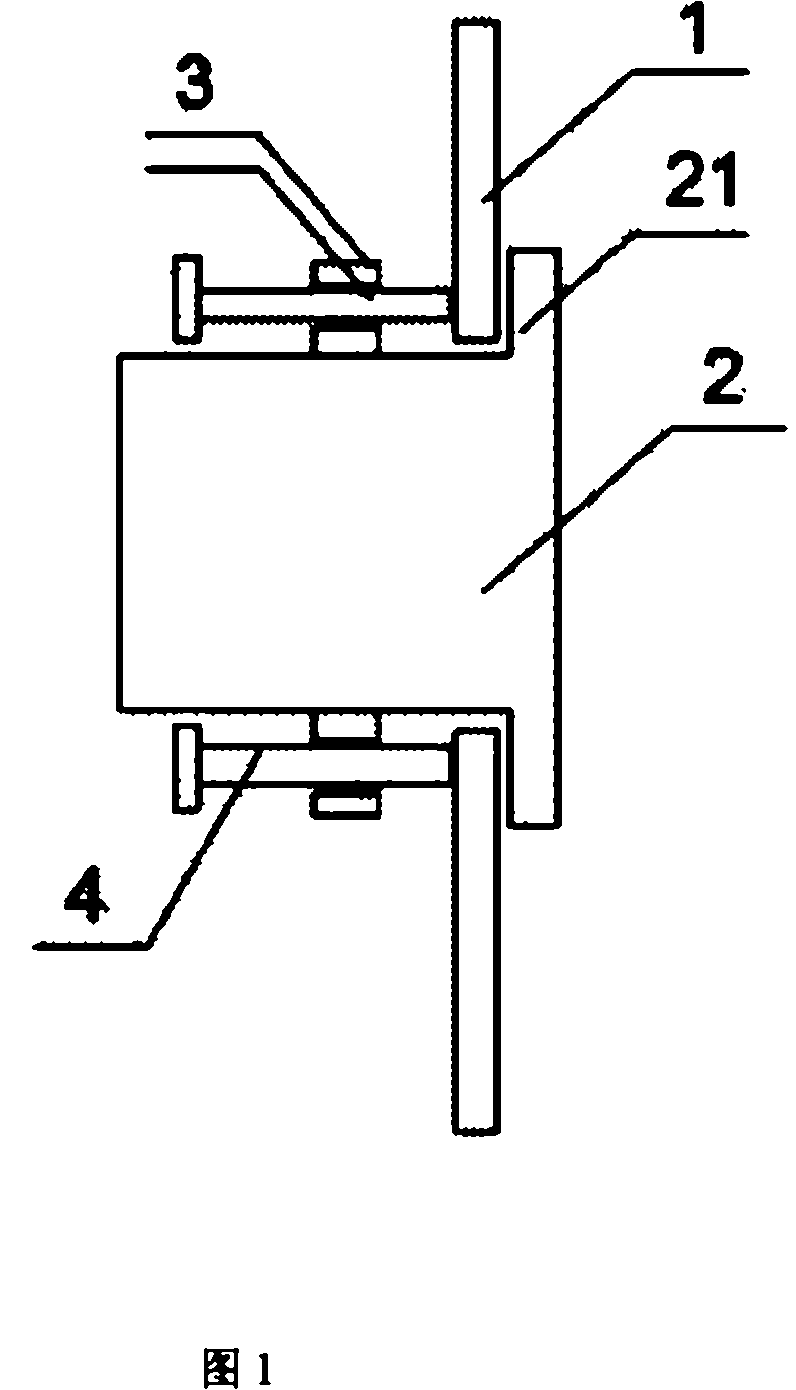

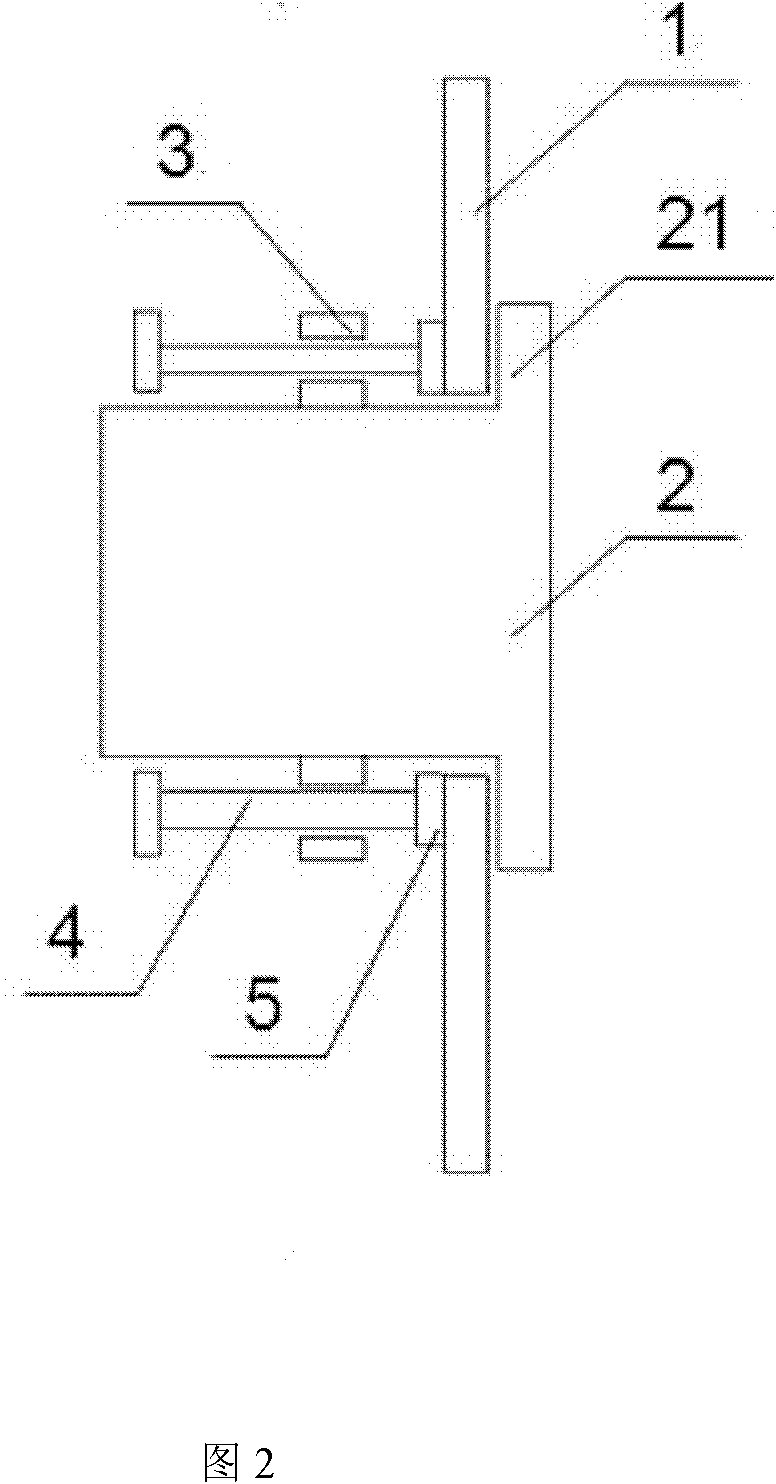

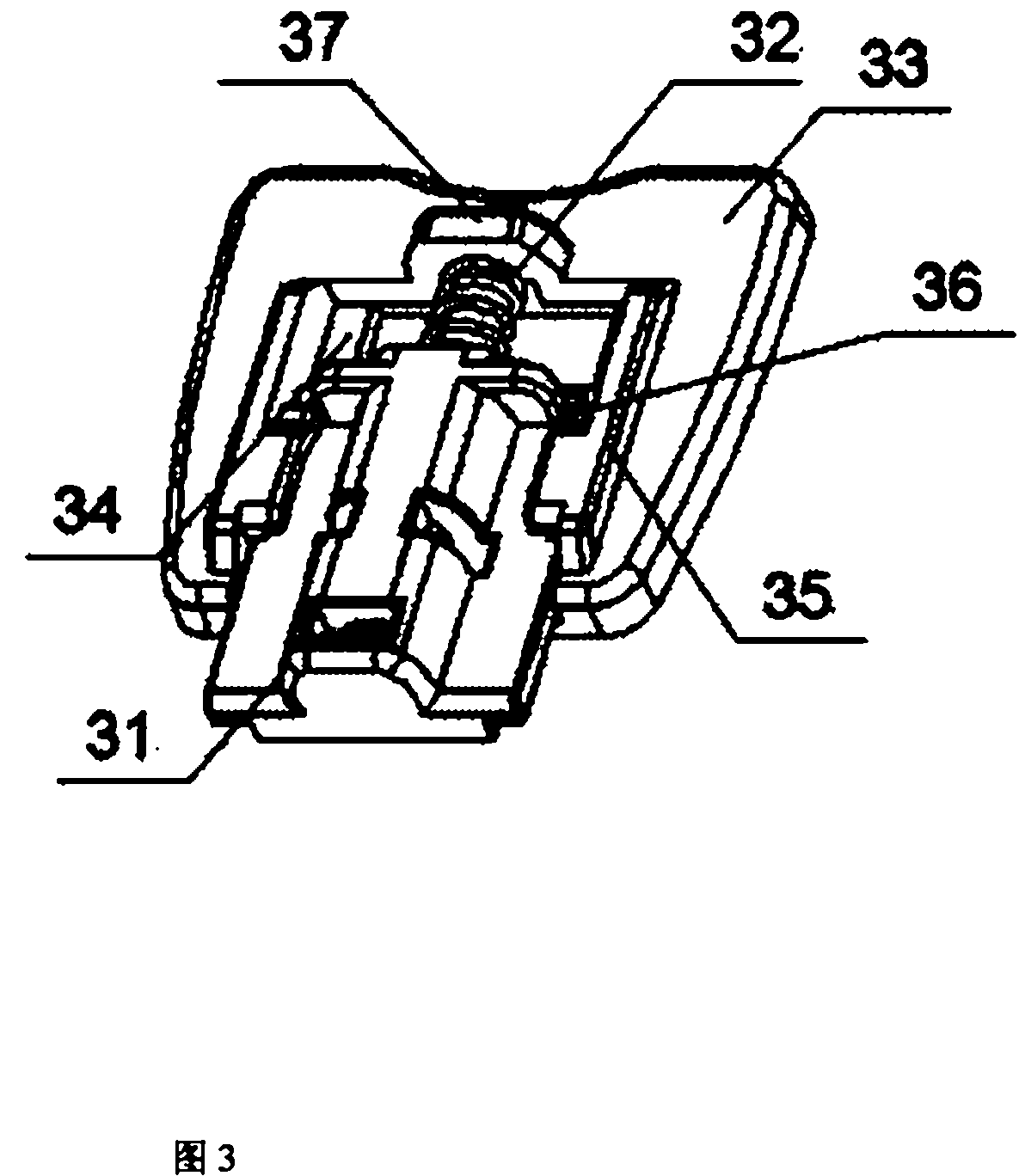

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] Such as Figure 3 to Figure 6 As shown, the fixing assembly provided by the embodiment of the present invention is mainly composed of three parts, which are a fixing frame 31 , a spring 32 and a supporting member 33 . The main body of the support 33 is a flat plate structure, and a strip slideway 34 is formed in the middle of the upper surface of the support piece 33. One end of the strip slideway 34 extends to the top of the support piece 31, and a baffle plate 37 is provided on the top of the other end. Limiting points 35 are symmetrically arranged on the edge of the strip slideway 34 and higher than the slideway position. A spring limiting column 39 is arranged at the center of the slideway 34 for limiting the movement path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com