Aluminium titanate nanofiber and preparation method thereof

A technology of nanofibers and aluminum titanate, which is applied in the field of aluminum titanate nanofibers and its preparation, can solve the problems of high equipment requirements, high doping costs, and high production costs, and achieve good thermal shock resistance, low thermal expansion coefficient, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

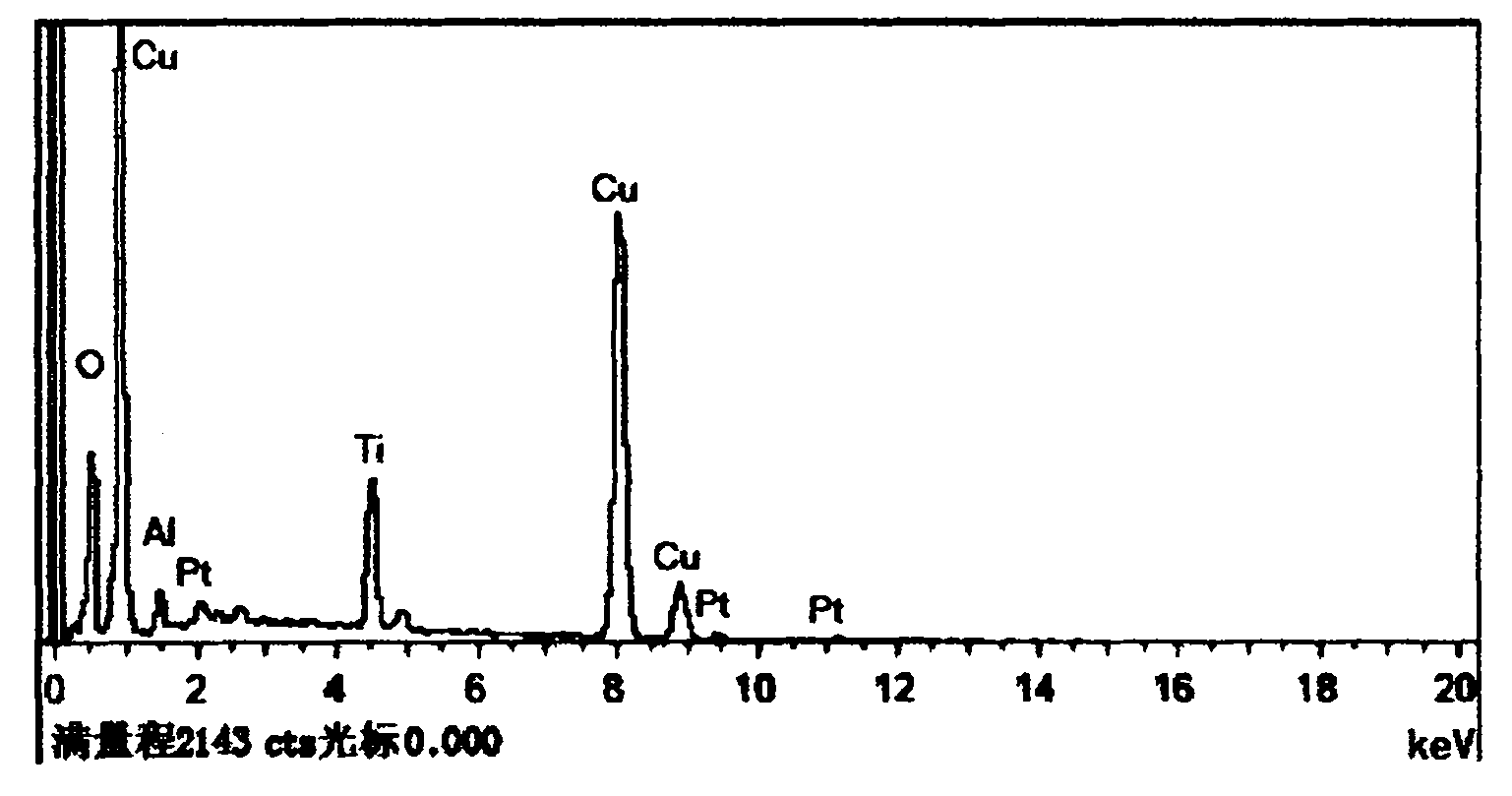

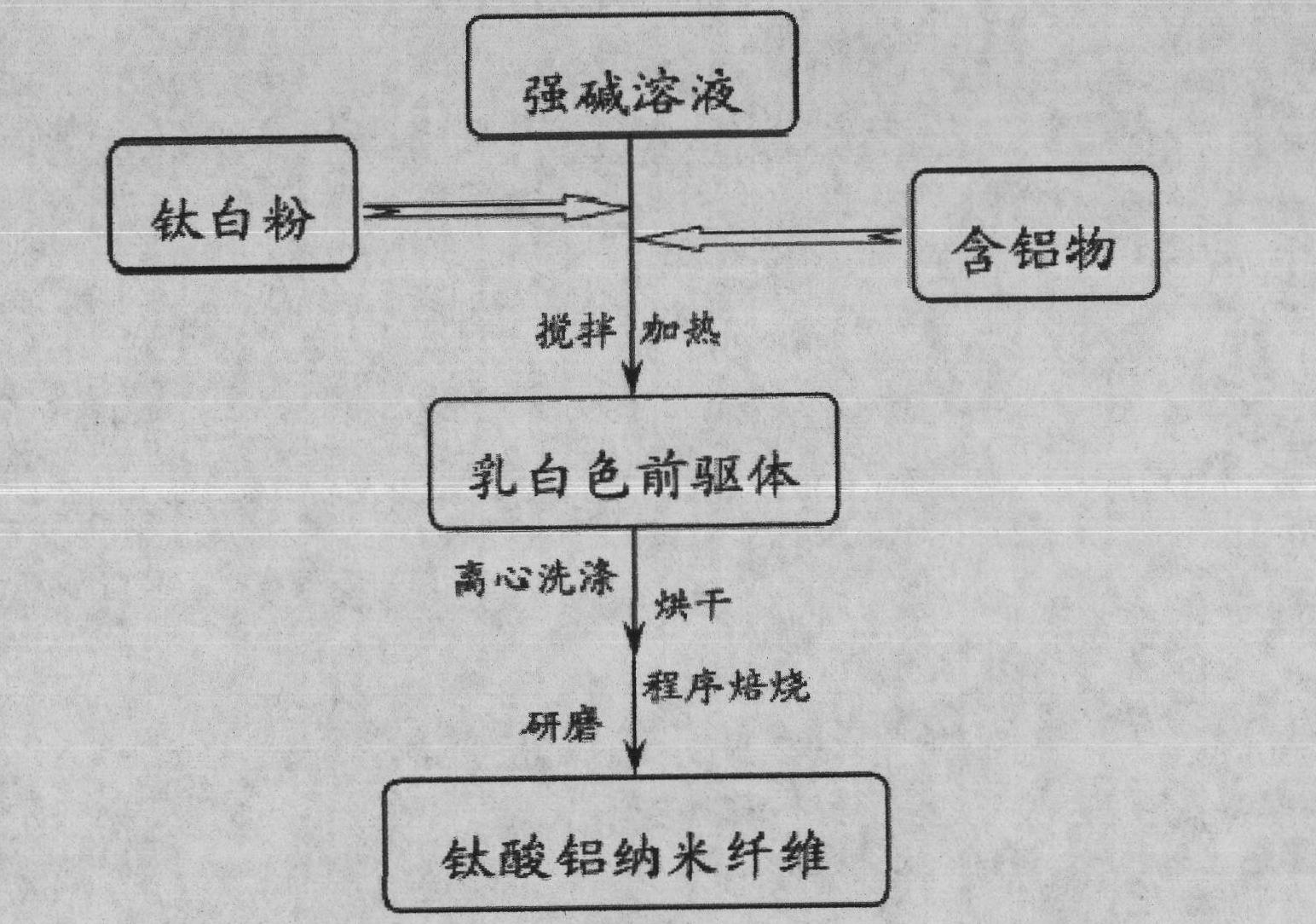

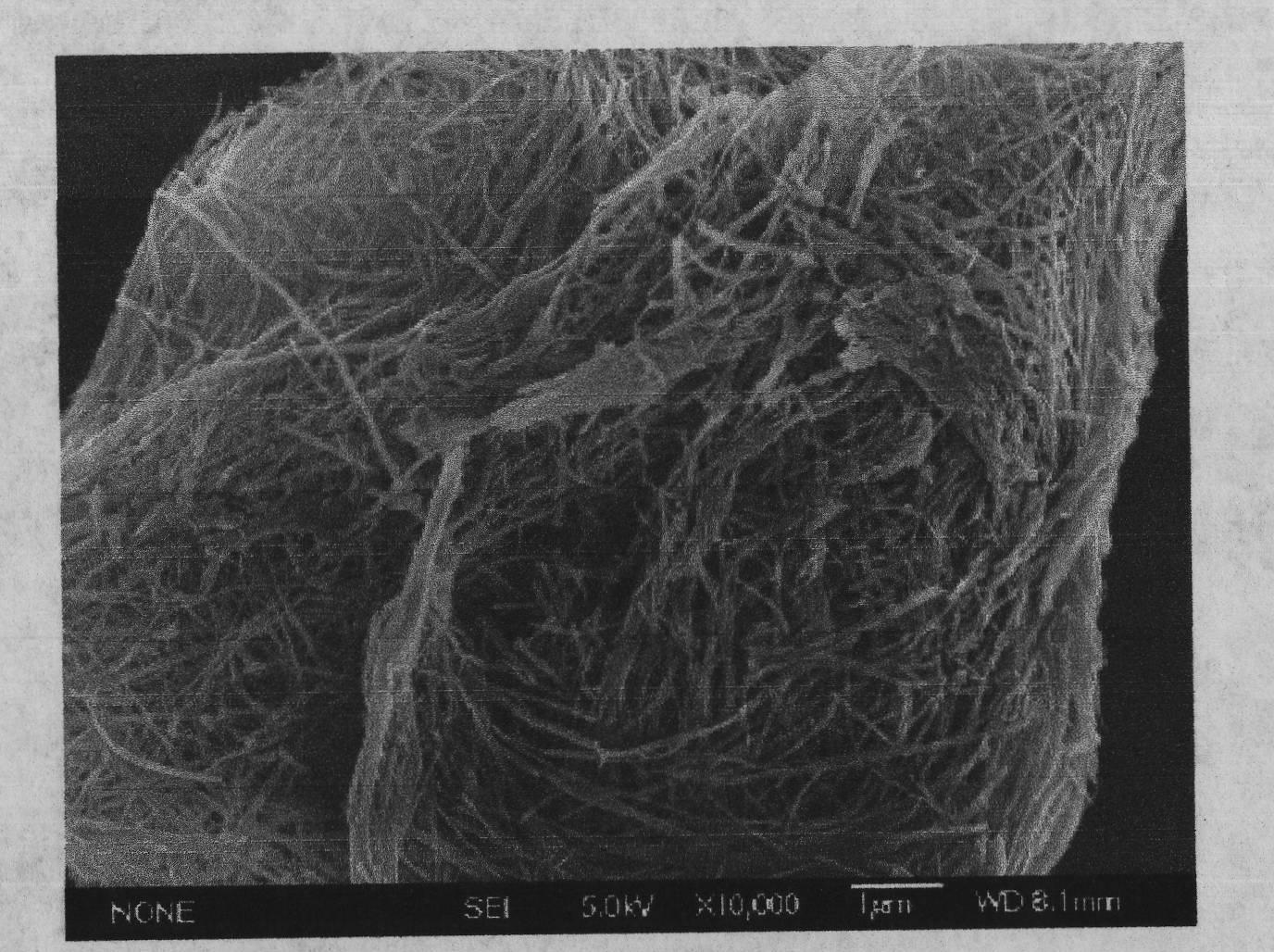

[0023] Weigh 5 grams of titanium dioxide and 16.7 grams of aluminum chloride, add 100 milliliters of 5mol L successively under mechanical stirring -1 The sodium hydroxide solution was transferred to a threaded sealed tank lined with polytetrafluoroethylene, and reacted at 100°C for 30 hours under airtight stirring. After the reaction tank was naturally cooled, a milky white precursor was obtained; The prepared milky white precursor is repeatedly centrifuged and washed until it does not contain sodium ions and chloride ions, and then the deionized precursor is dried at 120°C; finally, the precursor is kept at 300°C for 300 minutes in a crucible electric furnace, and 1300°C After heat preservation for 60 minutes and programmed firing, the aluminum titanate nanofibers with a diameter of about 45-65 nm and a length of about 3-8 μm were obtained by manual grinding in a porcelain crucible.

Embodiment 2

[0025] Weigh 3 grams of titanium dioxide and 16.3 grams of aluminum nitrate, add 50 milliliters of 6mol L successively under ultrasonic dispersion -1 Potassium hydroxide solution, transferred to a threaded sealed tank lined with polytetrafluoroethylene, and reacted at 210 ° C for 6 hours under airtight stirring. After the reaction tank was naturally cooled, a milky white precursor was obtained; followed by deionized water. The prepared milky white precursor was repeatedly centrifuged and washed to contain no potassium ions and nitrate ions, and then the deionized precursor was dried at 120°C; finally, the precursor was kept at 500°C for 120 minutes and 900°C in a crucible electric furnace. After 180 minutes of heat preservation at ℃ and programmed roasting, it is manually ground in a porcelain crucible to obtain aluminum titanate nanofibers with a diameter of about 35-50 nm and a length of about 5-12 μm.

Embodiment 3

[0027] Weigh 6 grams of titanium dioxide and 25.7 grams of aluminum sulfate, and add 75 milliliters of 8mol L successively under ultrasonic dispersion -1 The sodium hydroxide solution was transferred to a threaded sealed tank lined with polytetrafluoroethylene, and reacted at 110°C for 20 hours under airtight stirring. After the reaction tank was naturally cooled, a milky white precursor was obtained; The prepared milky white precursor was repeatedly centrifuged and washed until it was free of sodium ions and sulfate ions, and then the deionized precursor was dried at 120°C; finally, the precursor was kept in a crucible electric furnace at 350°C for 270 minutes, 1200°C After heat preservation at ℃ for 90 minutes and programmed calcination, low-speed ball milling can obtain aluminum titanate nanofibers with a diameter of about 20-30 nm and a length of about 10-30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com