Optical element, manufacturing method thereof and backlight module

A technology of optical components and manufacturing methods, applied in optical components, optics, nonlinear optics, etc., can solve problems such as spacing and thickness specifications, and inability to optimize designs, so as to achieve the effect of eliminating moiré patterns and optimizing designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

In the following embodiments, the x-axis direction will represent the second direction, and the y-axis direction will represent the first direction. However, those of ordinary skill in the art can understand that this is only for the convenience of presentation, not the first direction and the first direction. Limitations made by the two directions.

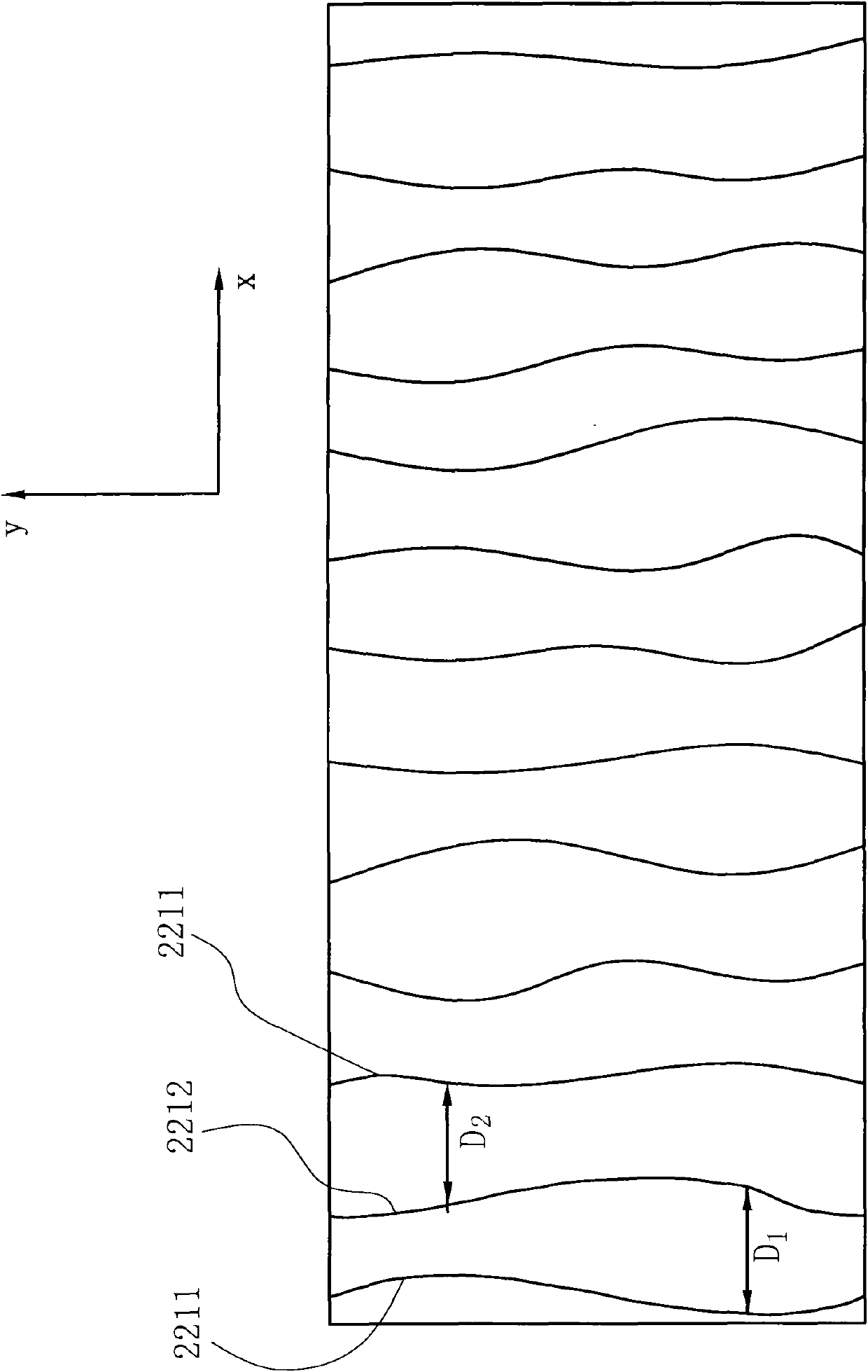

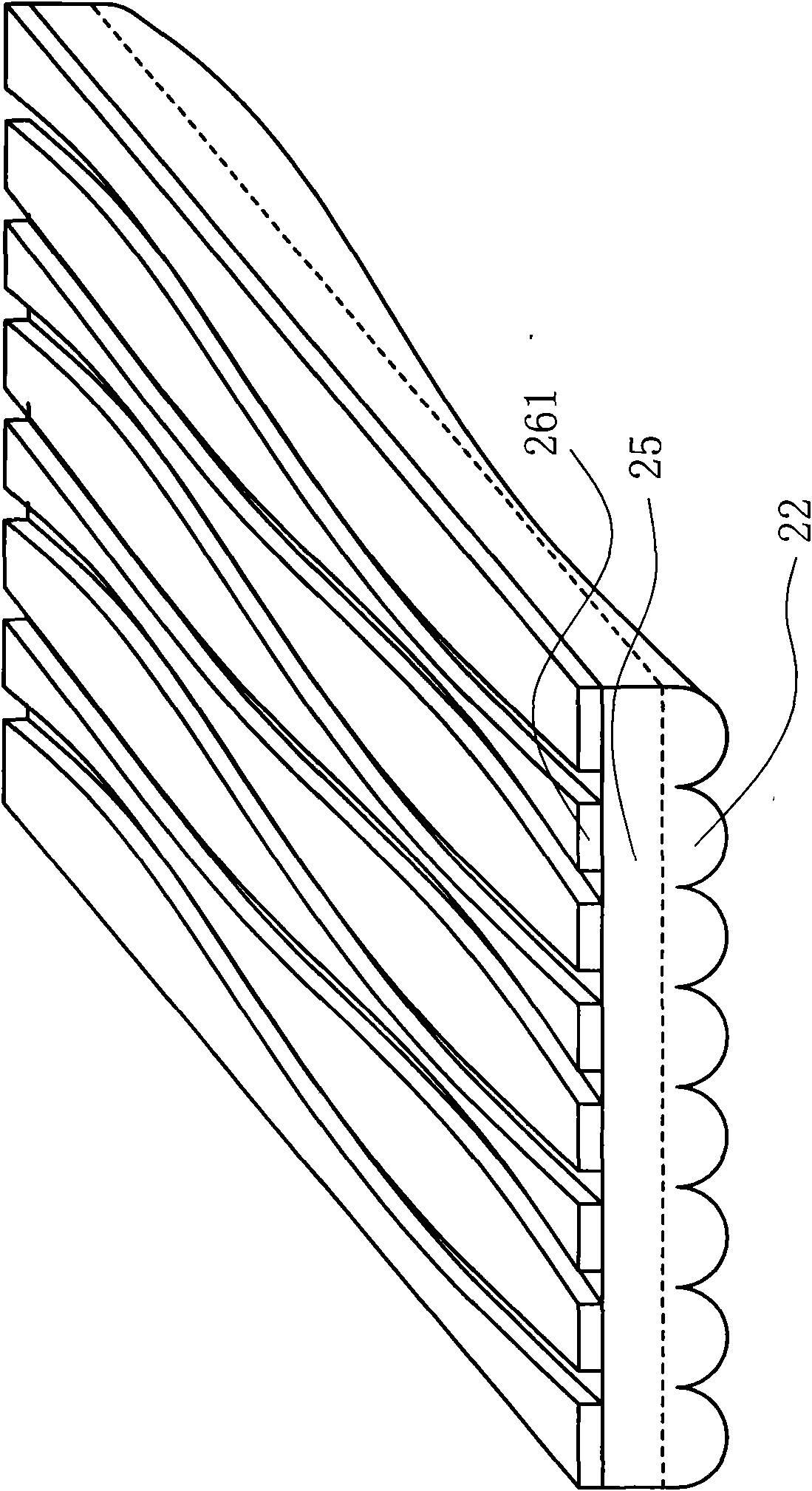

Please refer to FIG. 2. FIG. 2 is a perspective view of the optical element according to the first embodiment of the present invention. The optical element 2 is substantially in the shape of a thin plate, which is, for example, arranged above the diffuser in the direct-lit backlight module, that is, on the light-emitting surface side of the diffuser. The light-emitting surface 21 of the optical element 2 has a plurality of microstructures 22, and the microstructures 22 are arranged on the light-emitting surface 21 along the X direction, and each microstructure 22 has a top edge 221. The function of these microstructures 22 is to co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap