New component insertion technology applied to rapid rotary braiding machine

A technology of components and technology, which is applied in the field of insertion and sealing devices, can solve problems that affect the working efficiency of the braiding machine, braiding errors, equipment downtime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

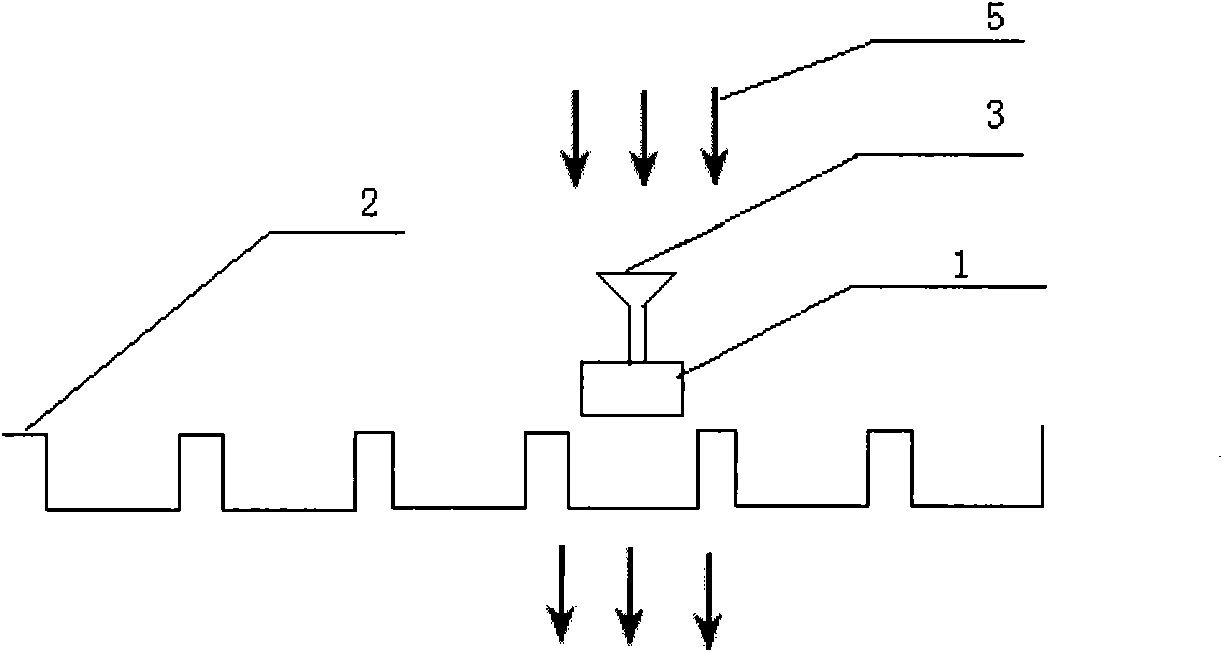

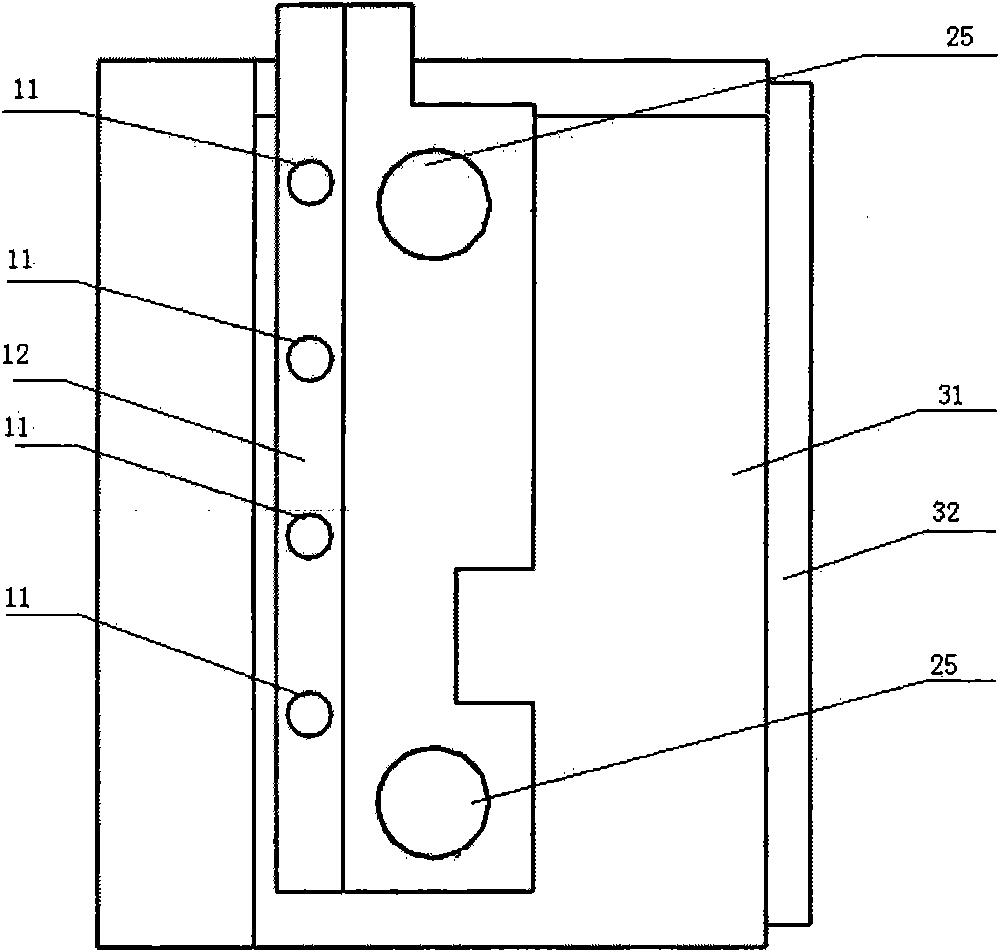

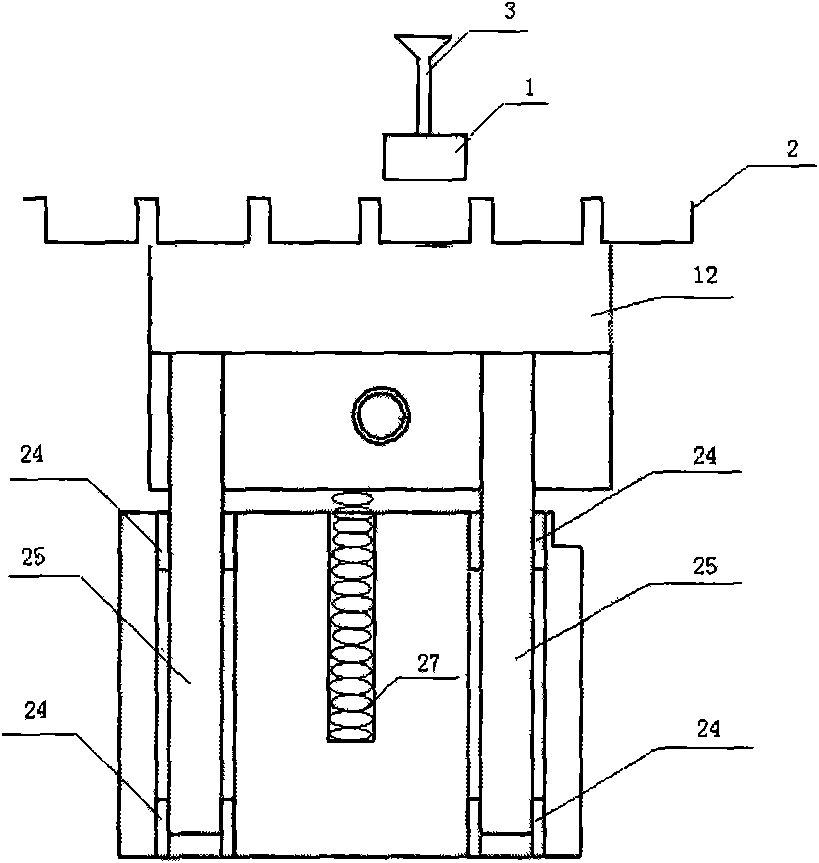

[0007] Figure 2 to Figure 6 It is the suction device of the present invention, and the base 32 installs the suction device on the braiding machine platform of the braiding machine. The sliding sleeve 24 that plays a supporting role is loaded into the abutment 31 to support the guide rod 25, and this device is easy to disassemble. The vacuum negative pressure is connected through the vacuum inlet 13, so that the entire vacuum cavity 12 is in a negative pressure state. The base 31 is equipped with a spring 27 with a certain elastic force, so that the vacuum cavity 12 is closely combined with the carrier tape 2, and the adsorption hole 11 is aligned with the small hole on the bottom surface of the carrier tape. After the suction nozzle 3 moves above the braiding station, it moves downward to insert the component 1 into the carrier tape 2. At this time, the suction nozzle 3 closes the vacuum and blows air to release the component 1. At the same time, the adsorption hole 11. Fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com