Micro mirror layer, liquid crystal on silicon (LCOS) display device and manufacturing method thereof

A technology of micro-mirror and backing layer, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of decreased reflectivity of aluminum reflective surface, difficulty of aluminum reflective surface, etc., and achieve the effect of high process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

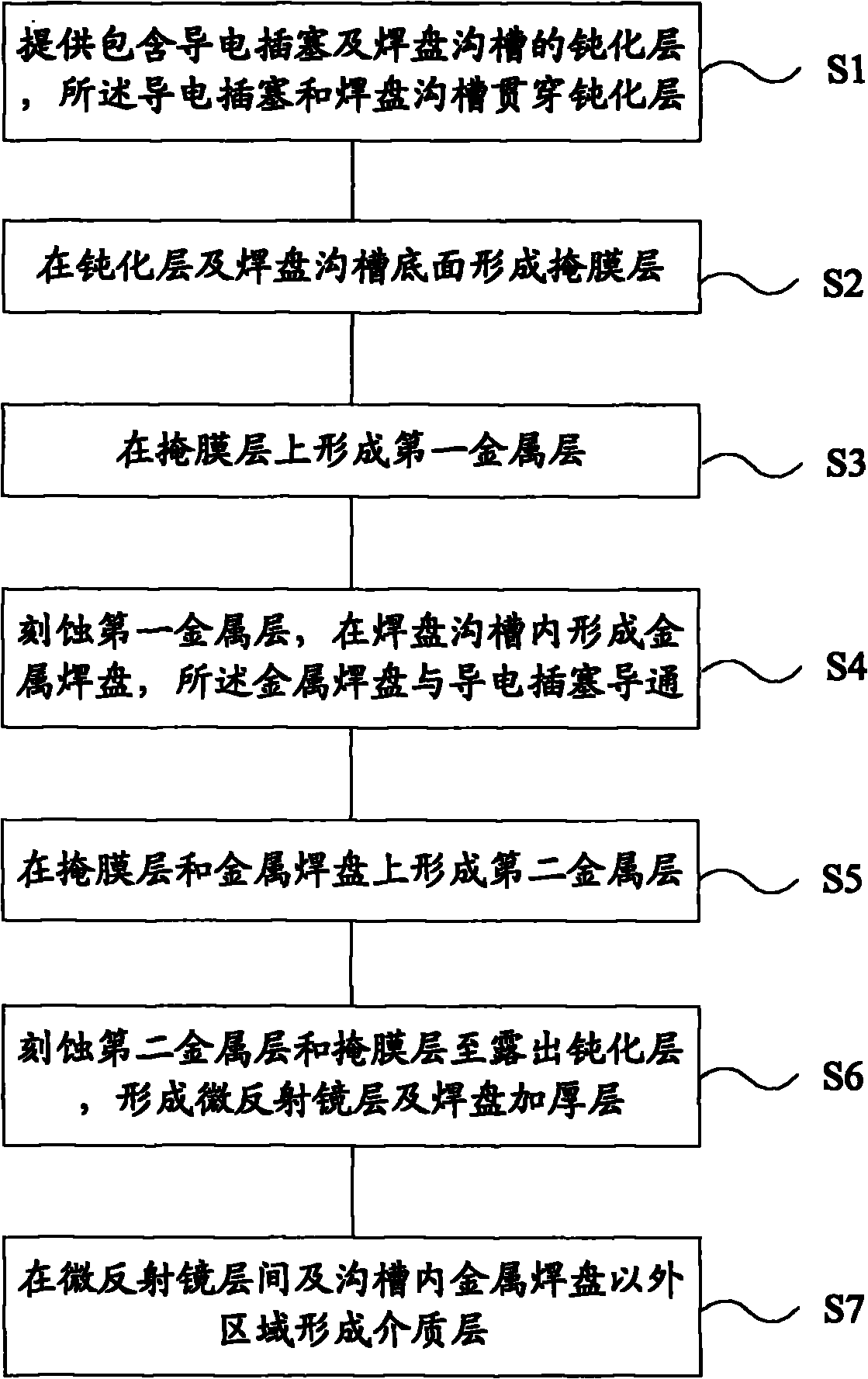

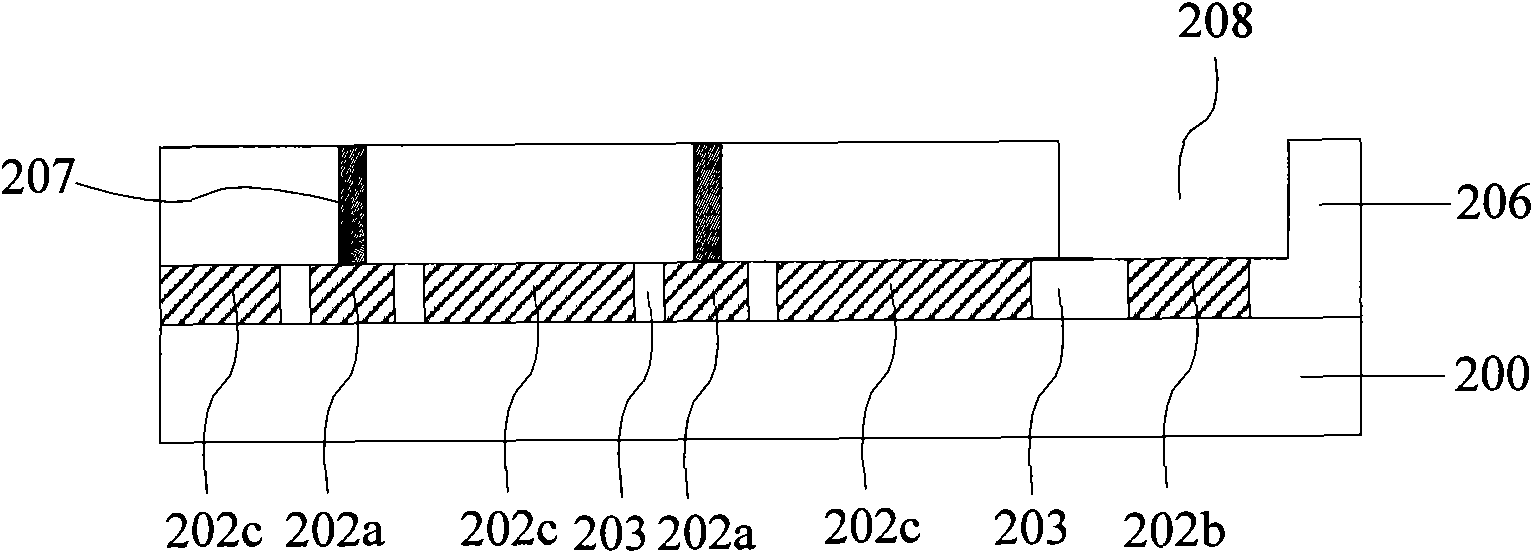

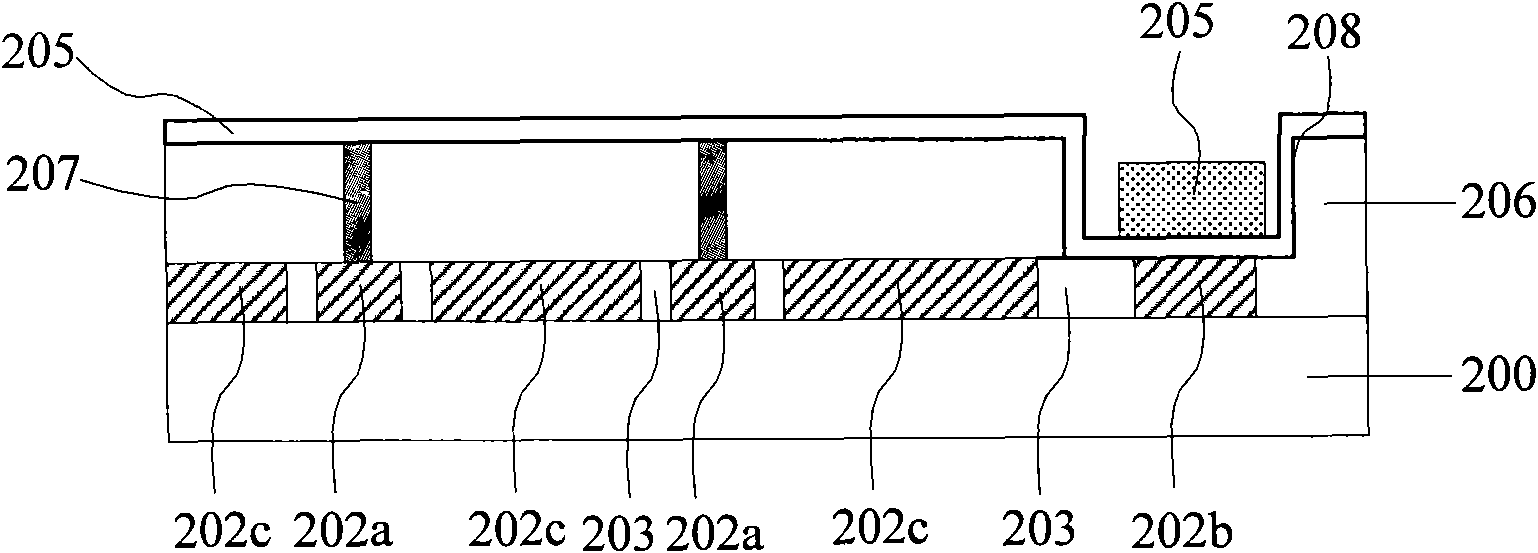

[0014] figure 1 It is a flow chart of a specific embodiment of the present invention for fabricating the micro-mirror surface in a silicon-based liquid crystal display device. Such as figure 1 As shown, step S1 is executed to provide a passivation layer including conductive plugs and pad grooves, and the conductive plugs and pad grooves penetrate the passivation layer; step S2 is executed to provide a passivation layer on the passivation layer and pad grooves. A mask layer is formed on the bottom surface; step S3 is performed to form a first metal layer on the mask layer; step S4 is performed to etch the first metal layer to form a metal pad in the pad groove, and the metal pad is connected to the conductive The plug is turned on; step S5 is performed to form a second metal layer on the mask layer and the metal pad; step S6 is performed to etch the second metal layer and the mask layer to expose the passivation layer to form a micromirror layer and Retaining the second metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com