Polishing composition

A composition, amino acid technology, applied in polishing compositions containing abrasives, electrical components, other chemical processes, etc., can solve the problems of reduced grinding speed and abrasive particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

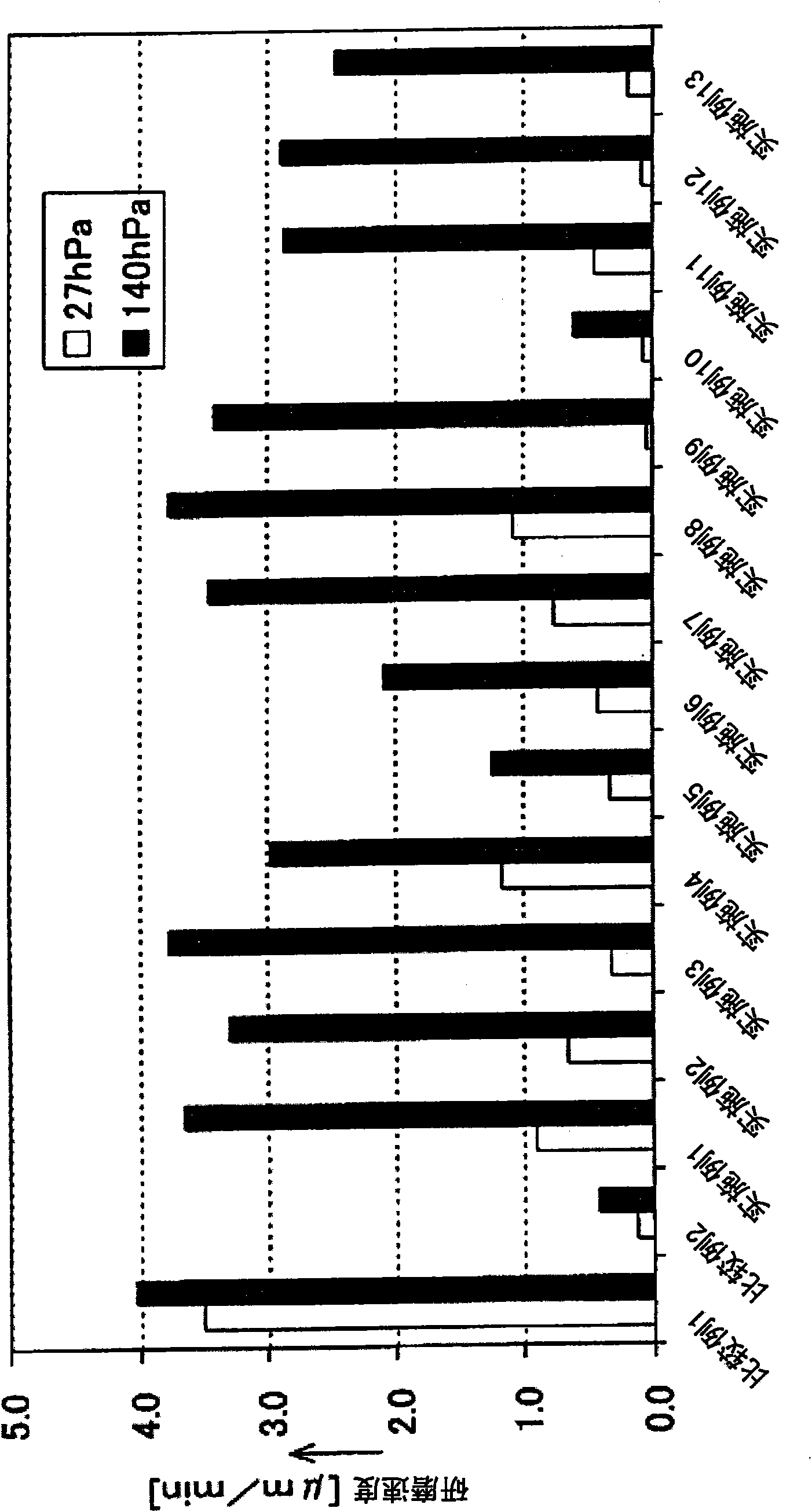

Embodiment 1

[0068] Ammonia 2% by weight

[0069] Hydrogen peroxide 0.5% by weight

[0070] Amino acid: Glycine 1% by weight

[0071] Dodecylbenzenesulfonic acid 0.5% by weight

[0072] Abrasive grains: Colloidal silica 2% by weight

[0073] water remainder

Embodiment 2

[0075] Ammonia 2% by weight

[0076] Hydrogen peroxide 0.5% by weight

[0077] Amino acid: alanine 1% by weight

[0078] Dodecylbenzenesulfonic acid 0.5% by weight

[0079] Abrasive grains: Colloidal silica 2% by weight

[0080] water remainder

Embodiment 3

[0082] Ammonia 2% by weight

[0083] Hydrogen peroxide 0.5% by weight

[0084] Amino acid: Serine 1% by weight

[0085] Dodecylbenzenesulfonic acid 0.5% by weight

[0086] Abrasive grains: Colloidal silica 2% by weight

[0087] water remainder

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com