High-adsorption-capacity room-temperature nitrogen oxide adsorbent and preparation method thereof

A technology of nitrogen oxides and high adsorption, which is applied in the field of NOx adsorbent and its preparation, loaded activated carbon adsorbent and its preparation, can solve the problems of small adsorbent capacity and weak adsorption force, etc., and achieve the effect of broad application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

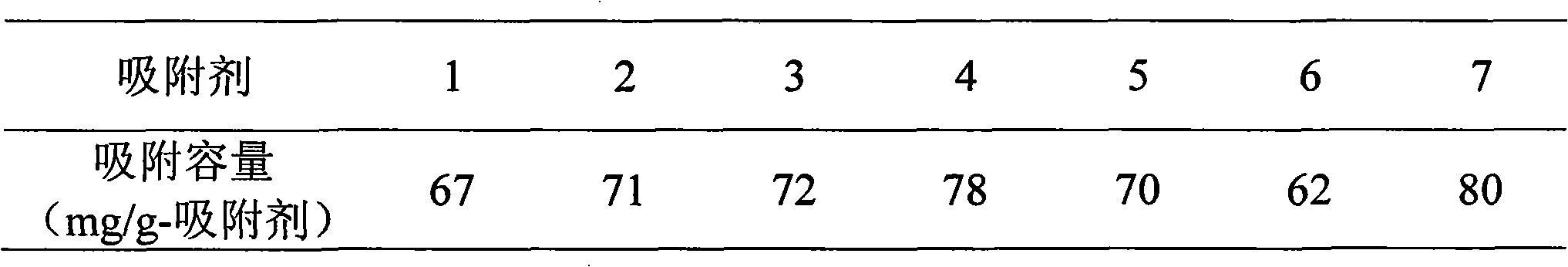

[0025] [Example 1]

[0026] Add 100g coconut shell activated carbon to 1000mL 2M nitric acid aqueous solution, shake and soak for 48h at room temperature, filter out the activated carbon after soaking, wash with deionized water several times, dry in 120℃ air and 400 in air ℃ roasting 4h; 40g zirconium oxychloride (ZrOCl 2 ·8H 2 O) and 16g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) Dissolve in deionized water and prepare 120mL solution, add the above activated carbon at room temperature, dry the activated carbon at 120℃ after immersing for 4h; dissolve 12g potassium hydroxide in 120mL deionized water, add the above activated carbon at room temperature, soak After 4 hours, the activated carbon was dried at 120°C and calcined in nitrogen at 300°C for 4 hours to obtain adsorbent 1. The adsorption capacity for NO is shown in Table 1.

Example Embodiment

[0027] [Example 2]

[0028] Add 100g of coconut shell activated carbon to 1000mL of 2M nitric acid and 20g of hydrogen peroxide in an aqueous solution, shake and immerse for 48h at room temperature, filter out the activated carbon after immersion, and wash it with deionized water for several times, in the air at 120℃ Drying and roasting in the air at 400℃ for 4h; 40g zirconium oxychloride (ZrOCl 2 ·8H 2 O), 16g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) and 7g gadolinium nitrate (Gd(NO 3 ) 3 .6H 2 O) Dissolve in deionized water and prepare 120mL solution, add the above activated carbon at room temperature, dry the activated carbon at 120℃ after immersing for 4h; dissolve 12g potassium hydroxide in 120mL deionized water, add the above activated carbon at room temperature, soak After 4 hours, the activated carbon was dried at 120°C and calcined at 300°C in nitrogen for 4 hours to obtain adsorbent 2. The adsorption capacity for NO is shown in Table 1.

Example Embodiment

[0029] [Example 3]

[0030] Use 22g manganese nitrate (50%Mn(NO 3 ) 2 Aqueous solution) instead of 16g copper nitrate in [Example 2], and other conditions are the same as [Example 2] to obtain adsorbent 3. The adsorption capacity for NO is shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap