Improved method of fresh kelp high-efficiency pretreatment and algin extraction processes for chemical engineering

An extraction process and a technology for alginate, applied in the field of alginate extraction process improvement, can solve the problems of difficulty in complete digestion, shorten the production time of alginate, kelp cell wall swelling and damage, etc., so as to reduce input cost, save input, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Examples:

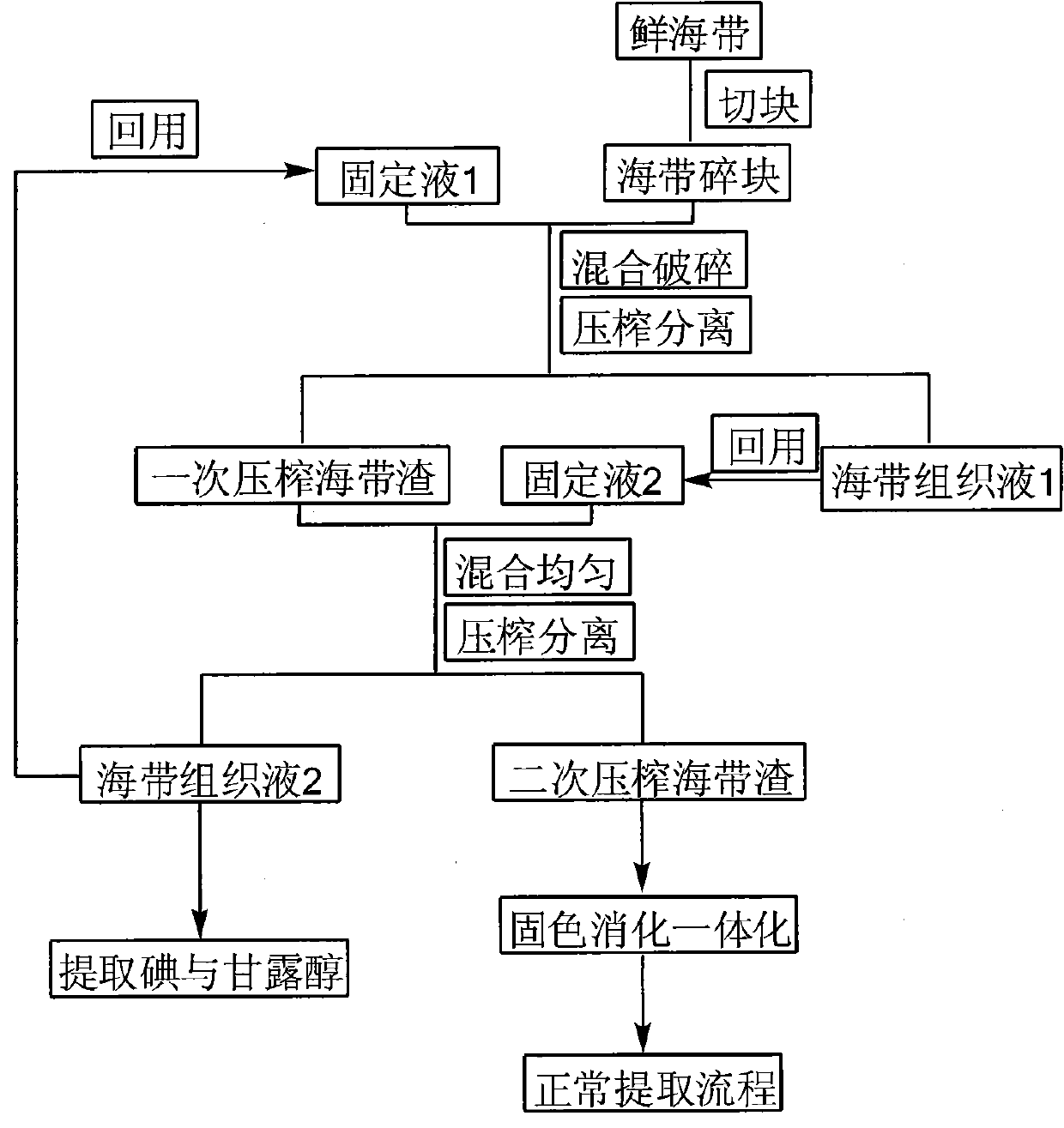

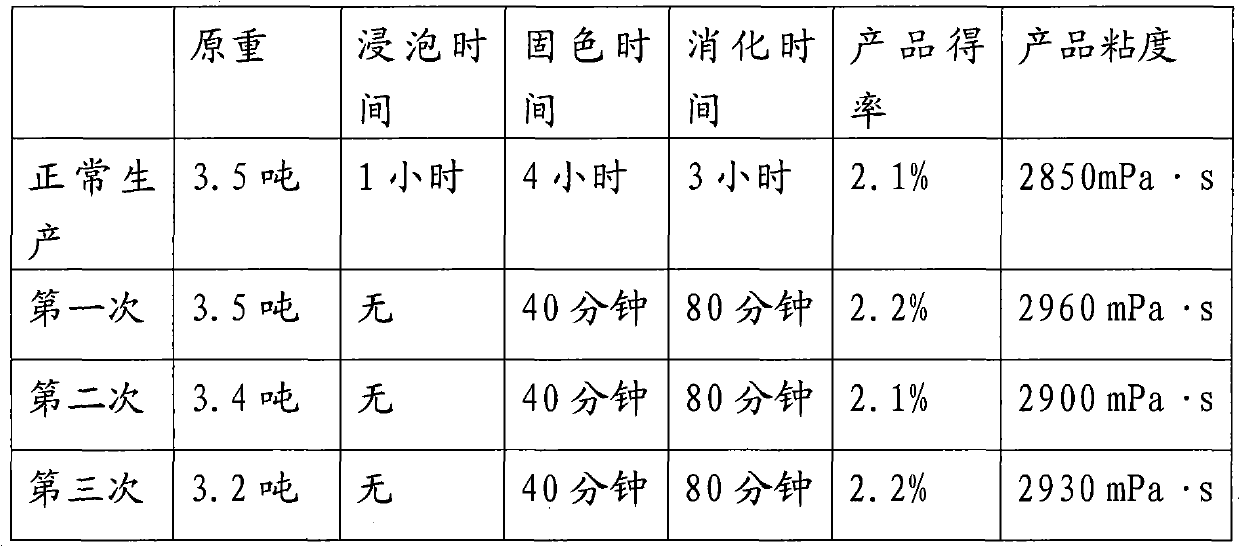

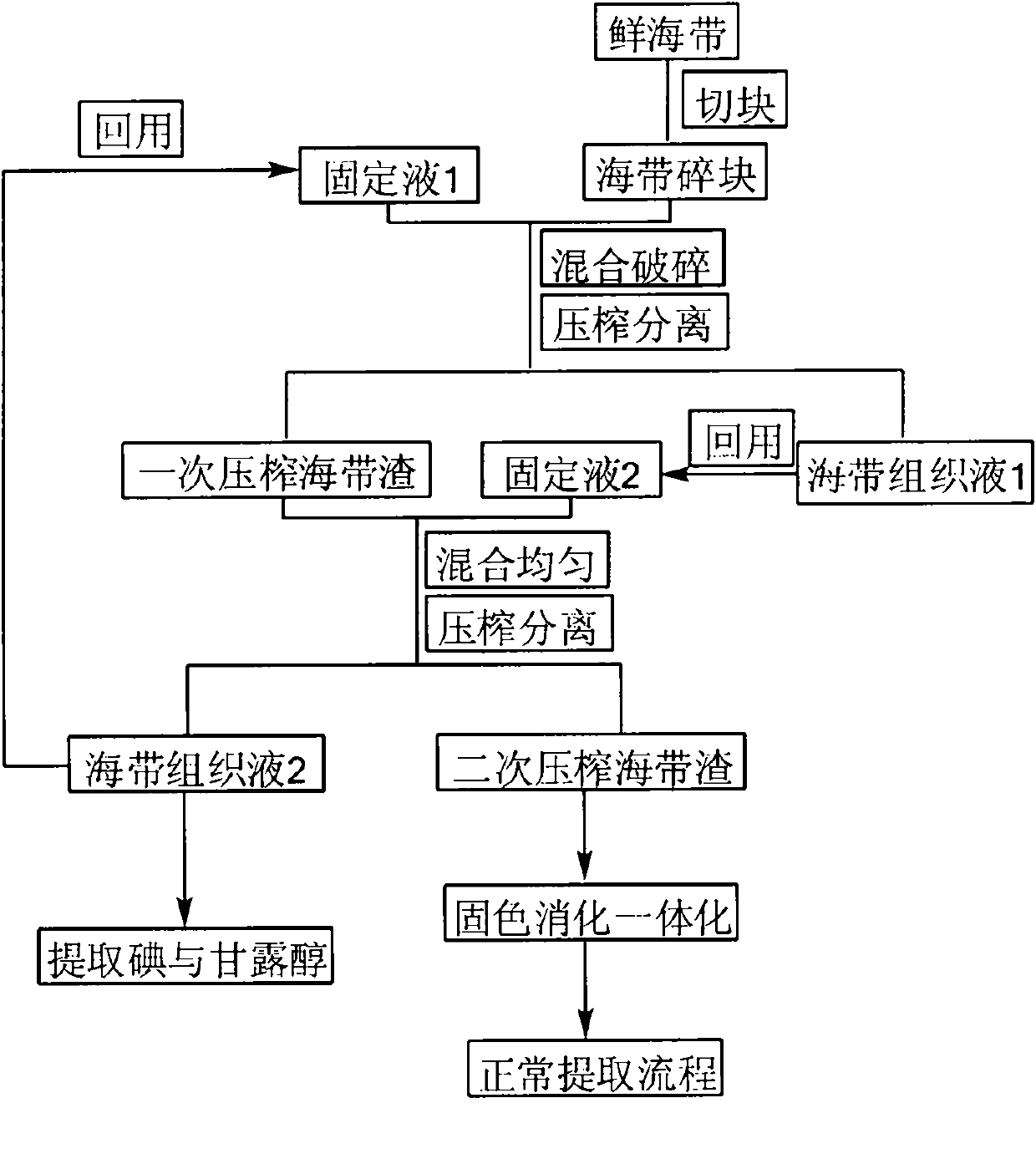

[0027] Choose about 3.5 tons of fresh kelp in the maturity period in July, cut it into 10-20cm kelp pieces through a vegetable cutting device, dissolve 25kg of calcium chloride in 0.7 tons of water, make up fixed liquid 1, and fix it according to the ratio of kelp pieces Liquid 1 is put into a large-scale tissue crushing equipment at a feed ratio of 5 to 1, and the tissue is crushed. After the kelp pieces are crushed into a slurry, they are sent to the pressing equipment for slag-liquid separation, and the kelp slag is about 1.4 tons after being crushed. Kelp tissue liquid 1 is about 2.7 tons, supplemented with 0.2 tons of water, 25kg calcium chloride is added, and fixed liquid 2 is prepared. After mixing with the primary pressed kelp residue, it is subjected to secondary pressing and separation to obtain 0.7 tons of kelp tissue fluid. 2 About 3.4 tons, of which 2.7 tons are used to extract iodine and mannitol, and 0.7 tons of kelp tissue fluid 2 is reserved.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap