Fireproof combined gas flue

A combined, flue gas technology, applied in the direction of vertical pipes, building components, buildings, etc., can solve the problems that affect the quality of the project, easy to crack, separate, low strength, etc., to improve the quality of the project, good structural integrity, and connection firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

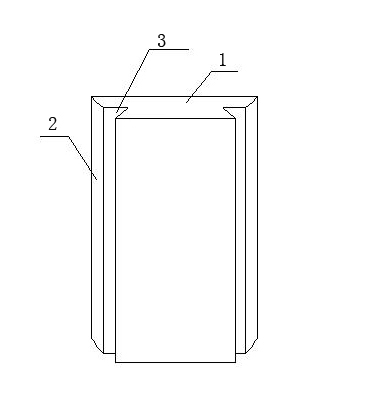

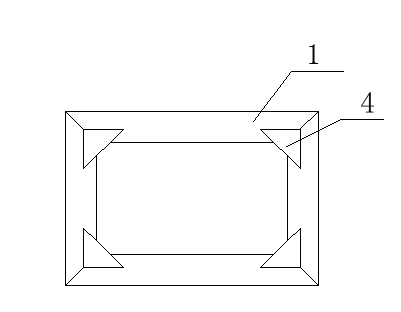

[0033] Embodiment one, with reference to the attached figure 1 , 2 , 3. The fire-proof combined flue gas channel adopts more than two flue gas channel plates 1, which are matched and combined with each other to form a complete flue gas channel. The sides of the two contacting flue gas channel plates are slopes that match each other. 2 shape, and there is a longitudinally penetrating groove on the slope 3, the two grooves contacting the flue gas channel plate are combined to form a columnar space, and the columnar space is filled with reinforcements, through which the flue gas channel plate connected together to form an integral structure. In this embodiment, the cross-sectional shape of the columnar space formed by the combination of two contacting flue gas channels is triangular; It is also triangular, directly inserted into the columnar space, and two adjacent flue gas duct panels are hooked together structurally and locked. In order to further improve the connection stre...

Embodiment 2

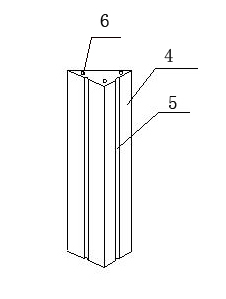

[0034] Embodiment two, referring to the attached Figure 4 , 5 6. In this embodiment, the cross-sectional shape of the columnar space formed by the combination of two contacting flue gas ducts is a combination of two geometric shapes, a combination of triangle and trapezoid, which further strengthens the integrity of the structure; the columnar space is filled with The reinforced body is a prefabricated reinforced cylinder 4, whose shape matches the columnar space, and is also a combination of triangle and trapezoid. It is directly inserted into the columnar space and connects the two adjacent flue gas duct panels structurally. , and lock it.

Embodiment 3

[0035] Embodiment three, with reference to the attached Figure 7 , in this embodiment, the four flue gas channel plates 1 are matched with each other to form a complete rectangular flue gas channel. There are longitudinal through grooves, and the grooves of two contacting flue gas duct plates are combined to form a columnar space, and cement mixture is poured into the columnar space as a reinforcement, and two adjacent flue gas duct plates are fixed on the Together, they become a whole; in order to improve the strength, the steel bar 7 is first set in the columnar space, and then the cement mixture is poured. Traditional methods such as bonding and rivet connection are also used between the flue gas duct plates to increase the strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com