Method for recycling waste acid and waste residues in production of herbicide oxadiazon

A technology for oxadiazon and herbicides, which is applied in the field of recycling and utilization of waste acid residues in the production of herbicide oxadiazon, can solve problems such as the decline in the production profit of the original oxadiazone, and achieves reduction of production costs and environmental protection and energy consumption. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

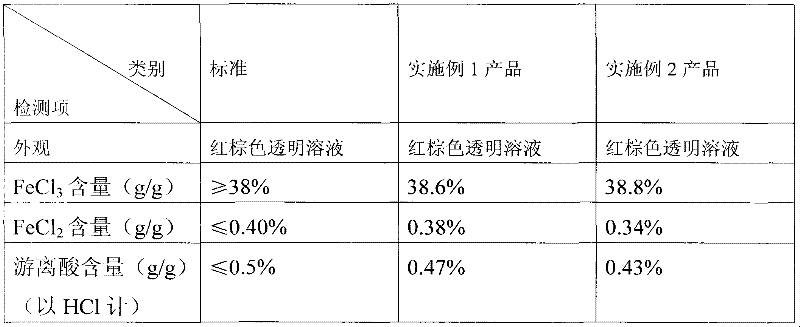

[0017] 1) Put 2 tons of waste acid with an HCl content of about 30% into a 3000L enamel reactor, and put 0.46 tons of waste residue (the iron content in the waste residue is about 60% to 70%) while stirring, and control the temperature at 85°C. Stir for 1.5 hours after throwing the waste residue. Sampling and measuring free acid content was 1.0%.

[0018] 2) Place it in the settling tank for 6-8 hours, take the supernatant and send it to the oxidation device, and dispose of a small amount of waste residue in the lower layer of the settling tank to the solid waste tank. The measured volume of the supernatant is 1900L, and the night specific gravity of the analyzed supernatant is 1.2940g / L, FeCl 2 The content is 12.2%, calculated FeCl 2 The molar mass is 2.3618kmol, according to Fe 2+ :Cl 2 = 1:0.525 (mol / mol) ratio into the chlorine gas 88kg, after the aeration, stirring reaction 2h, sampling analysis Fe 2+ Residue was 0.26%.

[0019] 3) Send the oxidized material to the ...

Embodiment 2

[0022] 1) Put 2 tons of waste acid with an HCl content of about 30% into a 3000L enamel reactor, and put 0.46 tons of waste residue (the iron content in the waste residue is about 60% to 70%) while stirring, and control the temperature at 80°C. Stir for 1 hour after throwing the waste residue. Sampling and measuring free acid content was 0.84%.

[0023] 2) Place it in the settling tank for 6-8 hours, take the supernatant and send it to the oxidation device, and dispose of a small amount of waste residue in the lower layer of the settling tank to the solid waste tank. The measured volume of the supernatant is 1880L, the analytical specific gravity is 1.3014g / L, FeCl 2 The content is 13.0%, calculated FeCl 2 The molar weight is 2.5044kmol, according to Fe 2+ :H 2 o 2 =1:0.525 (mol / mol) Add 44.7kg of hydrogen peroxide dropwise, stir for 2 hours, and take samples to analyze Fe 2+ Residue was 0.26%.

[0024] 3) Send the oxidized material to the concentration tank for concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com