Manufacturing method of copper-aluminum composite terminal and composite terminal manufactured thereby

A copper-aluminum composite and terminal technology, which is used in the preparation of copper-aluminum composite terminals and the field of copper-aluminum composite terminals, can solve the problems of reduced strength of copper-aluminum transition joints, burnt contacts, and increased contact surface resistance, so as to improve the overall safety performance. , the effect of increasing the copper-aluminum contact area and reducing the risk of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be further described with reference to the following embodiments:

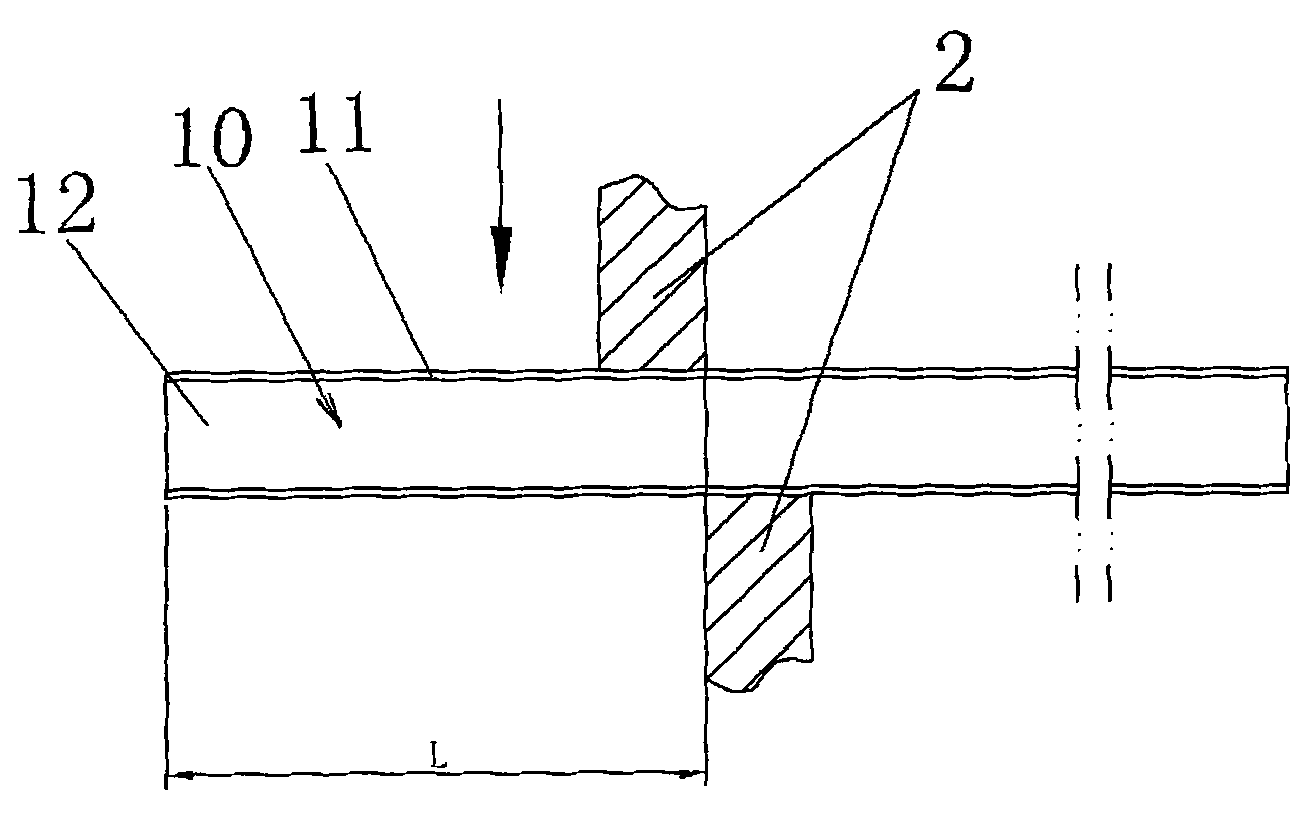

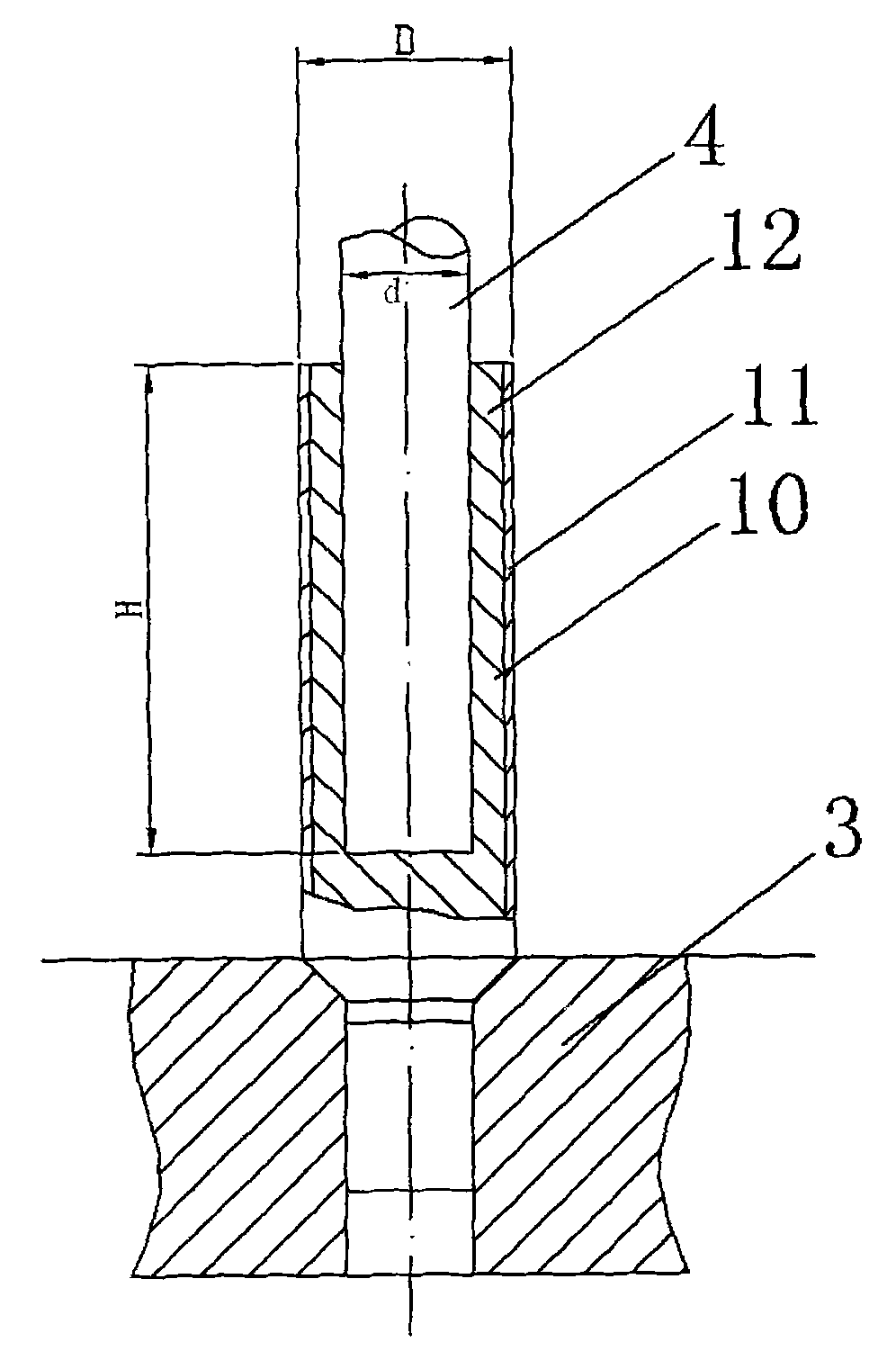

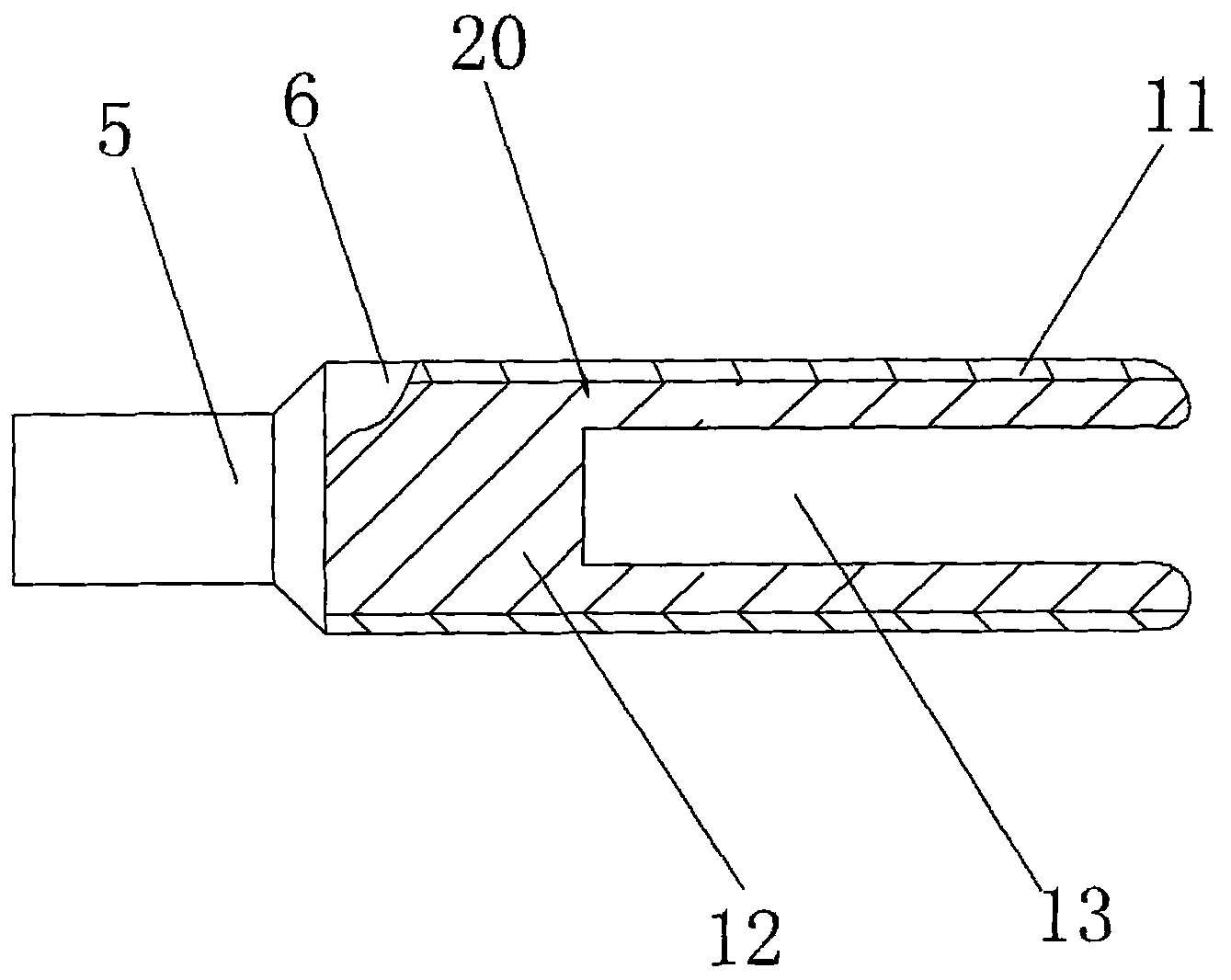

[0030] The method for preparing a copper-aluminum composite terminal of the present invention has specific steps as follows:

[0031] The first step is to choose to prepare a copper-clad aluminum bimetallic composite solid rod. This copper-clad aluminum bimetallic composite solid rod can be obtained through market purchase. The specific requirements are: A. The copper-aluminum bonding rate is above 85%. It determines the conductivity and yield of the final finished copper-aluminum composite terminal. For example, if the copper-aluminum adhesion rate is too low, the final finished copper-aluminum composite terminal has poor conductivity, and the copper-aluminum layer may be separated during processing. This phenomenon leads to a decrease in the yield rate; B. The thickness of the copper layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap