Continuous heat-transfer printing system of steel plate belt

A technology of thermal transfer and thermal transfer paper, applied in transfer printing, rotary press, printing, etc., can solve the problems of insecure quality, complex sealing device, poor transfer quality, etc., and achieve easy operation and control. Automation, improving the efficiency of thermal transfer printing, and ensuring the effect of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

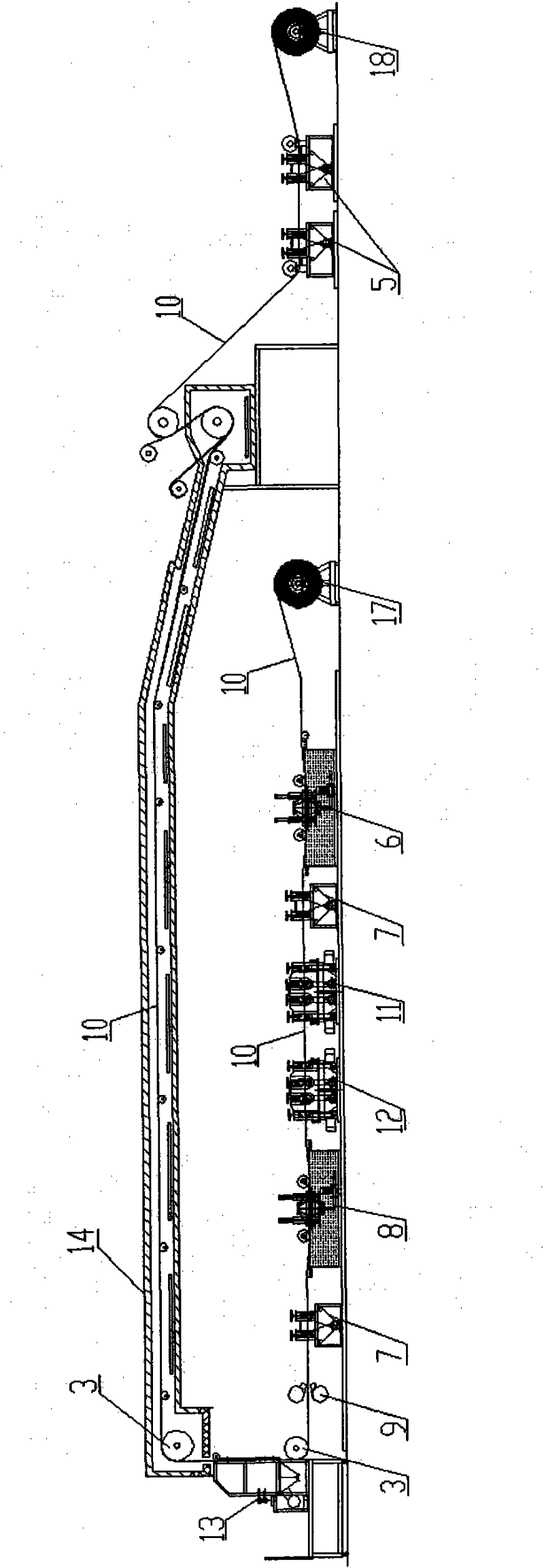

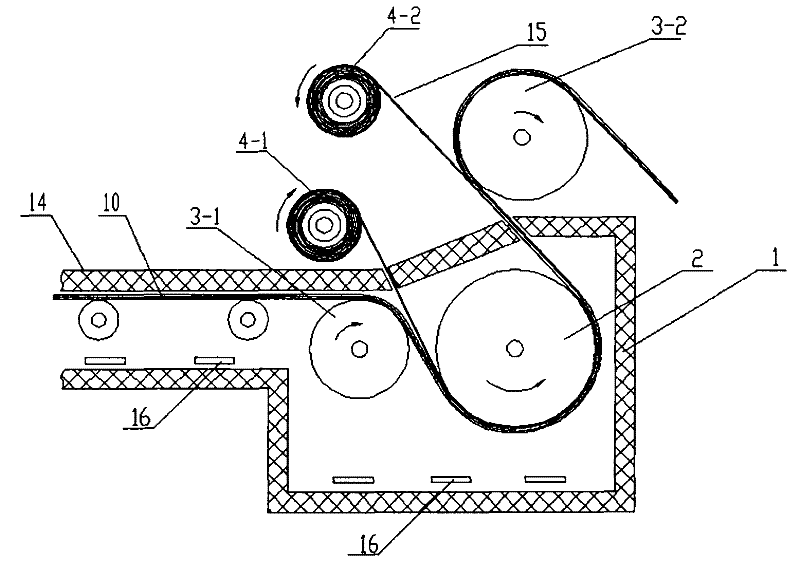

[0024] See attached figure 1 In the structure of a specific embodiment of the present invention, an unwinding machine 17, a cleaning machine 6, a water rolling machine 7, a degreasing machine 11, a texturing machine 12, a rinsing machine 8, a water rolling machine 7, a drying machine 9, a spray Powder machine 13, heating tunnel 14, continuous heat transfer printing equipment for roller-type steel plates and strips, pulling machine 5 and winder 18; two guide rollers 3 are vertically arranged between the drying machine 9 and the heating tunnel 14 , the steel plate strip 10 runs vertically between the two guide roller shafts 3, and turns back and travels horizontally at the upper guide roller shaft 3, and enters the heating tunnel 14; 11 and the top of the texturing machine 12; the powder spraying machine 13 is arranged between the two guide rollers 3;

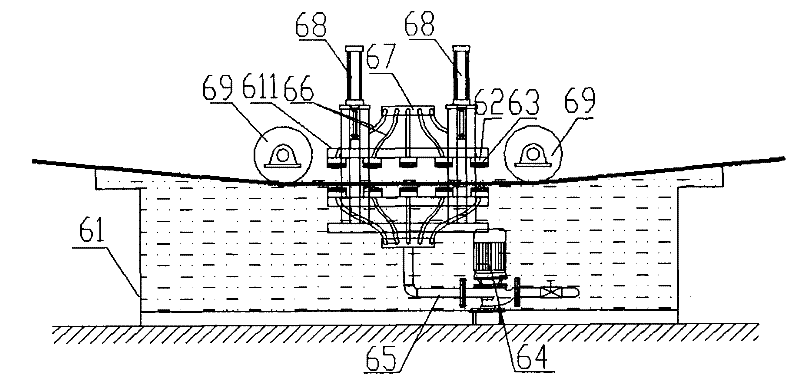

[0025] See attached Image 6 , the unwinding machine 17 includes a support 171, a mandrel 172 and a magnetic powder brake 174...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com