Steel strip continuous thermal transfer process and special continuous thermal transfer equipment

A technology of thermal transfer printing and thermal transfer paper, applied in printing, printing devices, etc., can solve the problems of thermal transfer printing technology such as cumbersome process, insecure quality, complicated sealing device, etc., and achieve easy-to-operate and control automation, Improve the efficiency of thermal transfer printing and ensure the effect of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples illustrate the invention in detail.

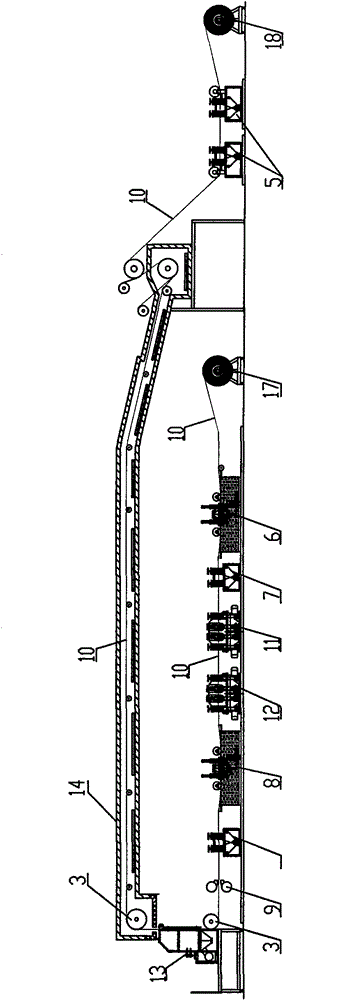

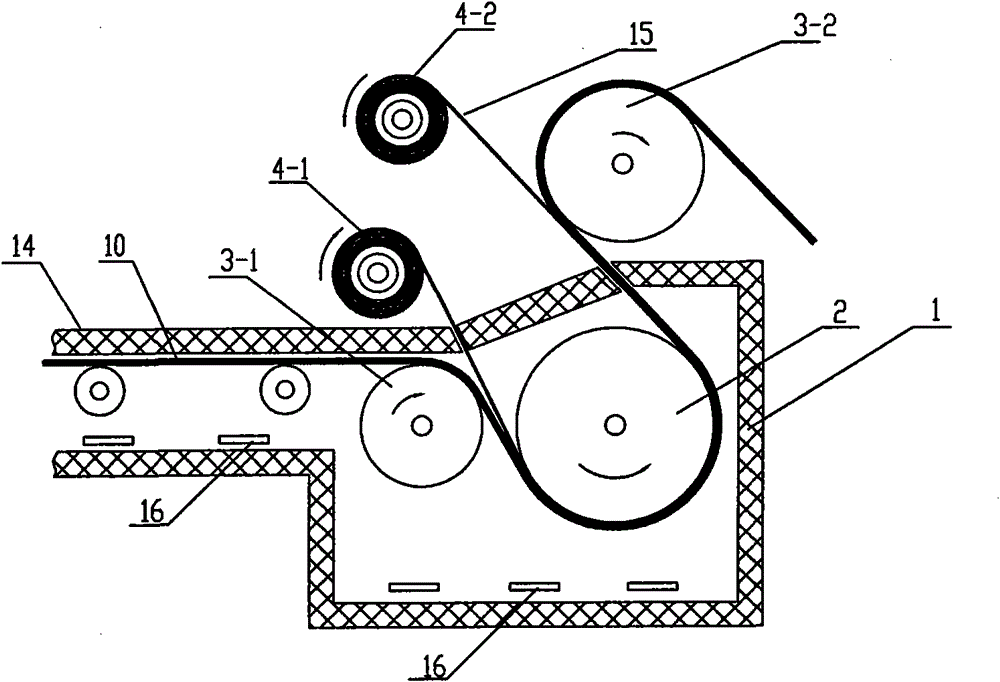

[0024] See attached figure 1 , the continuous thermal transfer process of the steel plate strip of the present embodiment is under the drive of the steel plate strip unwinder and the winder, if necessary, a puller 5 can be set, and the steel plate strip 10 is released by the unwinder 17 and Continuous advance, successively go through cleaning machine 6 pre-degreasing cleaning, water rolling machine 7 rolling water, degreasing machine 11 degreasing, texturing machine 12 texturing, rinsing machine 8 rinsing, water rolling machine 7 water rolling and drying machine 9 drying, Then change into a vertical row through two vertically arranged guide roller shafts 3, and complete the powder spraying process by a powder sprayer 13 vertically arranged on one side of the steel plate strip, and the steel plate strip 10 is recovered by the second guide roller shaft 3 It travels horizontally, enters the heating tunnel 14 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com