Vertical circular seam welding machine

A circular seam welding machine and vertical technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of low welding qualification rate and low production efficiency, reduce labor intensity, simplify clamping process, shorten the The effect of welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

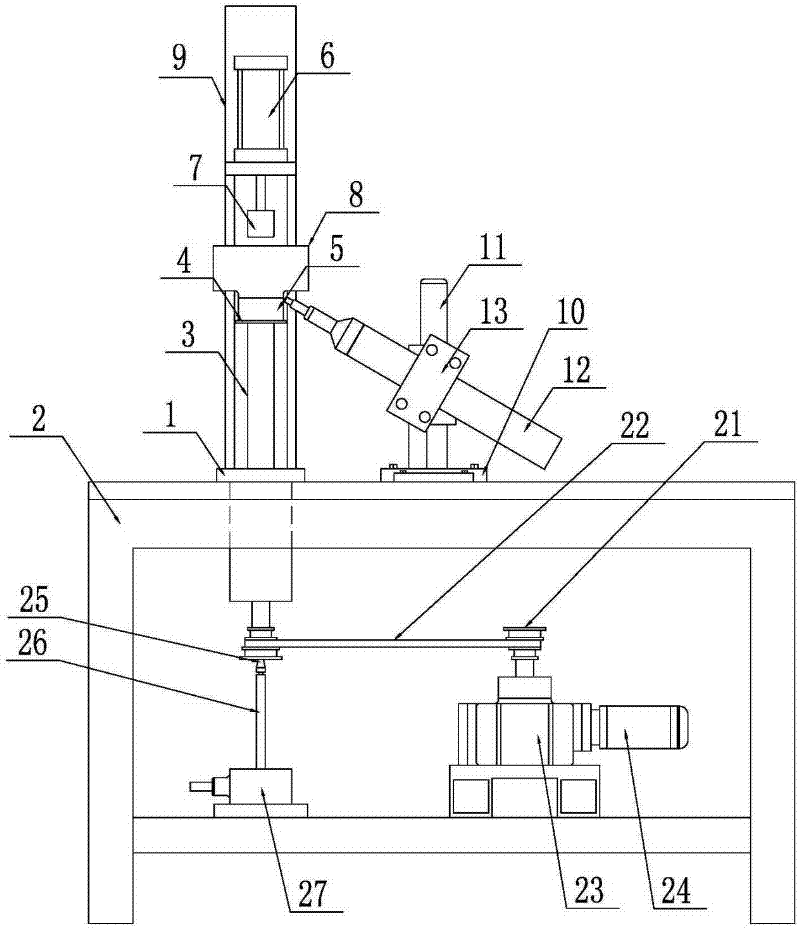

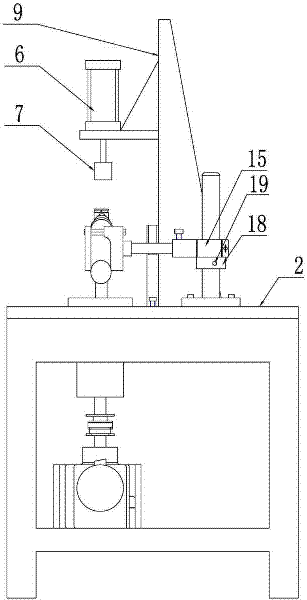

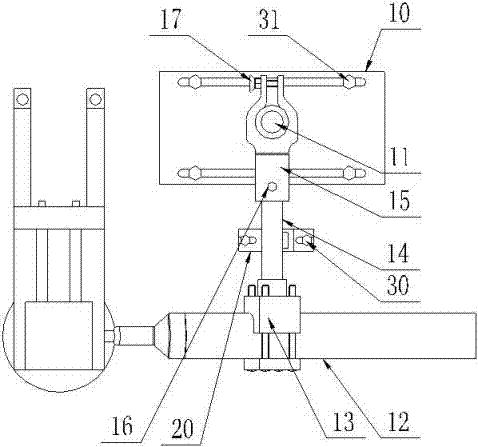

[0024] like figure 1 , 2 , The vertical girth welding machine shown in 3 adopts a vertical structure to clamp the product to be processed (three-way semi-finished product 8), the workbench 2 is provided with a spindle installation hole, and the nest 1 is vertically fixed on the spindle of the workbench 2. In the bore, the upper and lower parts of nest 1 are fitted with bearings (see Figure 4 ), the main shaft 3 is installed inside the nest 1, the main shaft 3 can rotate in the nest 1, and the inside of the main shaft 3 is provided with a through hole for transmitting the protective gas (the protective gas can be carbon dioxide or Argon). like Figure 5 and Image 6 As shown, the lower part of the fixed shaft 4 is a connecting part 41, and the upper part is a product seat 42. There is a step 43 between the connecting part 41 and the product seat 42. The connecting part is screwed to the upper end of the main shaft 3. The product seat 42 is used to fix the product The stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com