Manufacture method for bending crooked pipe

A manufacturing method and bending technology, which is applied in the manufacturing field of common fittings for pipeline connections, can solve the problems of residual filler, high manufacturing cost, and large power required, and achieve the effects of reducing difficulty, long service life, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

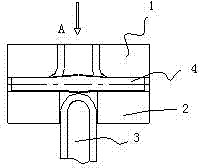

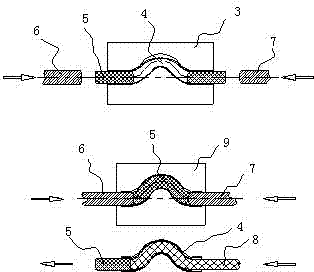

Image

Examples

Embodiment 2

[0023] The difference from Example 1 is that the first step in this example is blanking, and the soft copper tube is cut with a cutting machine to the theoretical development length of the product plus a margin of 3%, and the second step uses Partial flattening, that is, using a flattening die to press the part of the round tube cut in the first step that needs to be bent into an elliptical shape on a hydraulic press. All the other parts are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com