Closed circulation method for sodium hypochlorite waste water treatment of acetylene purification process in polyvinyl chloride (PVC) production by calcium carbide method

A technology for cleaning acetylene and sodium hypochlorite, which is applied in neutralizing water/sewage treatment, water/sewage treatment, natural water treatment, etc., can solve problems such as secondary pollution and waste of resources, improve safety, reduce acetylene loss, and The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

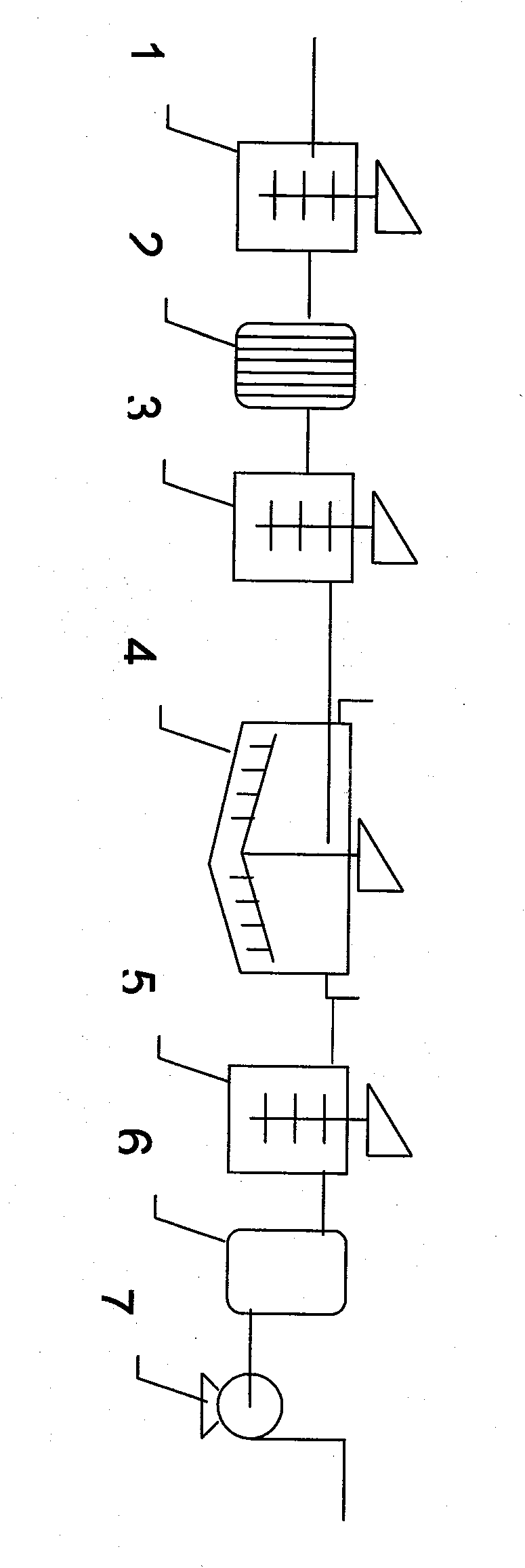

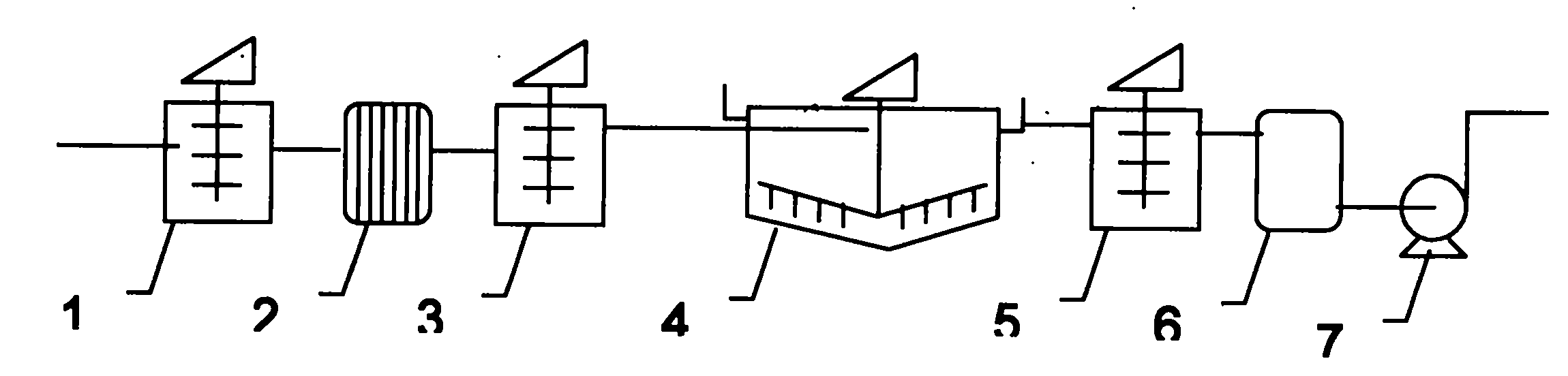

[0017] Embodiment two, at first the sub-sodium wastewater of the original production unit is sent to the neutralization reactor 1; the sub-sodium wastewater containing acetylene is added with 10% NaOH aqueous solution in the reactor 1, and after reacting for 10 minutes, the adjusted pH value is 11. Pump the effluent to send it to the heat exchanger, and the temperature of the water after heat exchange is 35°C; the effluent enters the reactor 2, and adds 300mg / l chemical agents for sulfur removal, phosphorus removal and phosphate removal to the reactor 2, and Add acetylene stabilizer at a concentration of 20 mg / l; pump the effluent to the settling separation reactor to separate sulfide, phosphorus compounds and other suspended matter from the supernatant. The separation time is 30 minutes. After treatment, the recycled water passes through the sodium preparation tank The device is mixed with 3% fresh hyposodium to obtain the 0.1-0.08% hyposodium solution required by the cleaning...

Embodiment 2

[0018] Embodiment three, at first the sub-sodium wastewater of the original production unit is sent to the neutralization reactor 1; the sub-sodium wastewater containing acetylene is added with 1% NaOH aqueous solution in the reactor 1, and after reacting for 10 minutes, the adjusted pH value is 6. Use the pump to lift the effluent to the heat exchanger, and the temperature of the water after heat exchange is 15°C; the effluent enters the reactor 2, and adds 500mg / l chemical agents for sulfur removal, phosphorus removal and phosphate removal in the reactor 2, and Add acetylene stabilizer at a concentration of 1 mg / l; pump the effluent to the sedimentation separation reactor to separate sulfide, phosphorus compounds and other suspended matter from the supernatant. The separation time is 120 minutes. After treatment, the recycled water passes through the sodium preparation tank The device is mixed with 1% fresh hyposodium to obtain the 0.1-0.08% hyposodium solution required by th...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com