Slip ring structure of high-voltage winding motor

A winding motor and slip ring technology, which is applied to asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of low protection level of slip rings and mismatch of protection levels of slip ring motors, and achieve improved protection level and simple structure. , the effect of obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

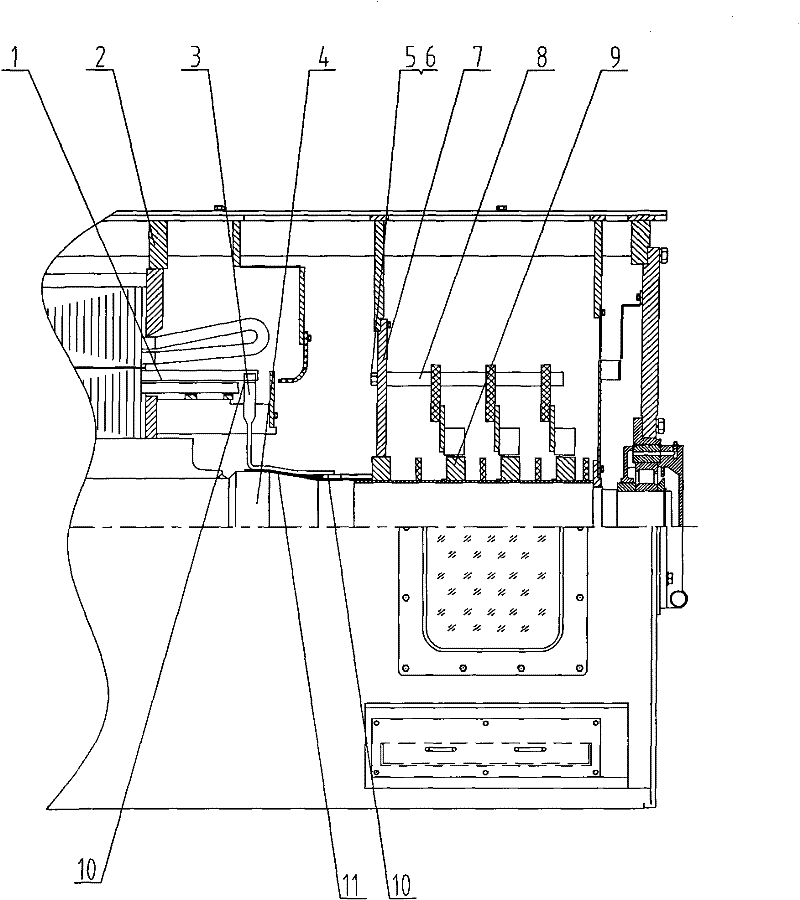

[0013] Such as figure 1 As shown, the present invention includes a rotor coil 1, a frame 2, a conductive bar 3, a shaft 4, a hex bolt 5, a washer 6, an inner end cover 7, a brush rod 8, a slip ring 9, solder 10 and a weft-free tape 11. The inner end cover 7 is fixed to the machine base 2 through the hexagonal bolt 5 and the washer 6, the brush rod 8 is screwed on the inner end cover 7, the slip ring 9 is put on the shaft 4 through the shrink-fit process, and the rotor coil 1 is connected with the conductive row with solder 10. One end of 3 is welded, the other end of conductive row 3 is welded with solder 10 and slip ring 9, and the place where conductive row 3 contacts shaft 4 is bound with latitude-free tape 11.

[0014] The installation process is as follows: First, fix the inner end cover 7 to the machine base 2 through the hexagonal bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com