Lithium iron phosphate powder manufacturing method, olivine structured lithium iron phosphate powder, cathode sheet using said lithium iron phosphate powder, and non-aqueous solvent secondary battery

A lithium iron phosphate and olivine-type technology, which is applied in electrode manufacturing, battery electrodes, structural parts, etc., can solve the problems of low lithium ion density and large positive electrode volume, and achieve improved current load characteristics and charge-discharge cycle characteristics. High fillability and improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

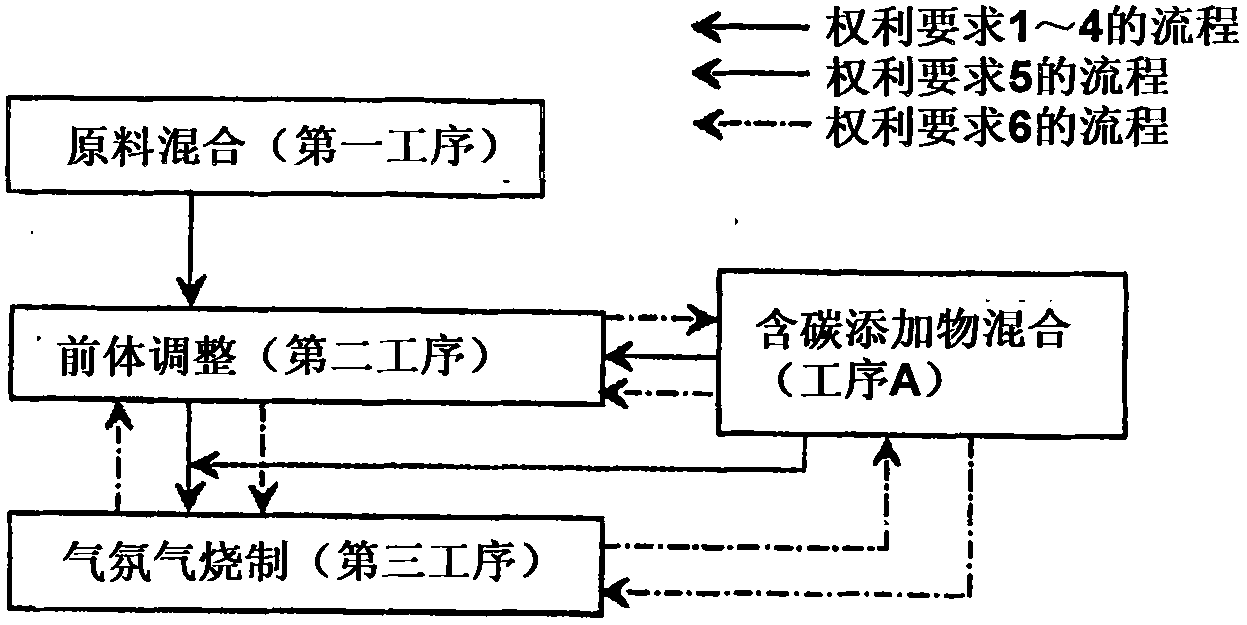

[0132] Using the iron raw material of No. 1 recorded in Table 1, use a crushing machine to mix LiH with the feed ratio Li / Fe=1.01 and P / Fe=1.01 recorded in Table 2. 2 PO 4 , to obtain 10g of lithium iron phosphate particle powder (first process).

[0133] Next, in ZrO 2 In the prepared ball mill container, adjust the mixed powder obtained in the first process and a specified amount of acetylene black with ethanol to make the slurry concentration 30wt%, and use 5mmΦ ZrO 2 The balls were crushed for 24 hours, intimately mixed, and the slurry was dried (removed solvent) at room temperature to obtain a precursor.

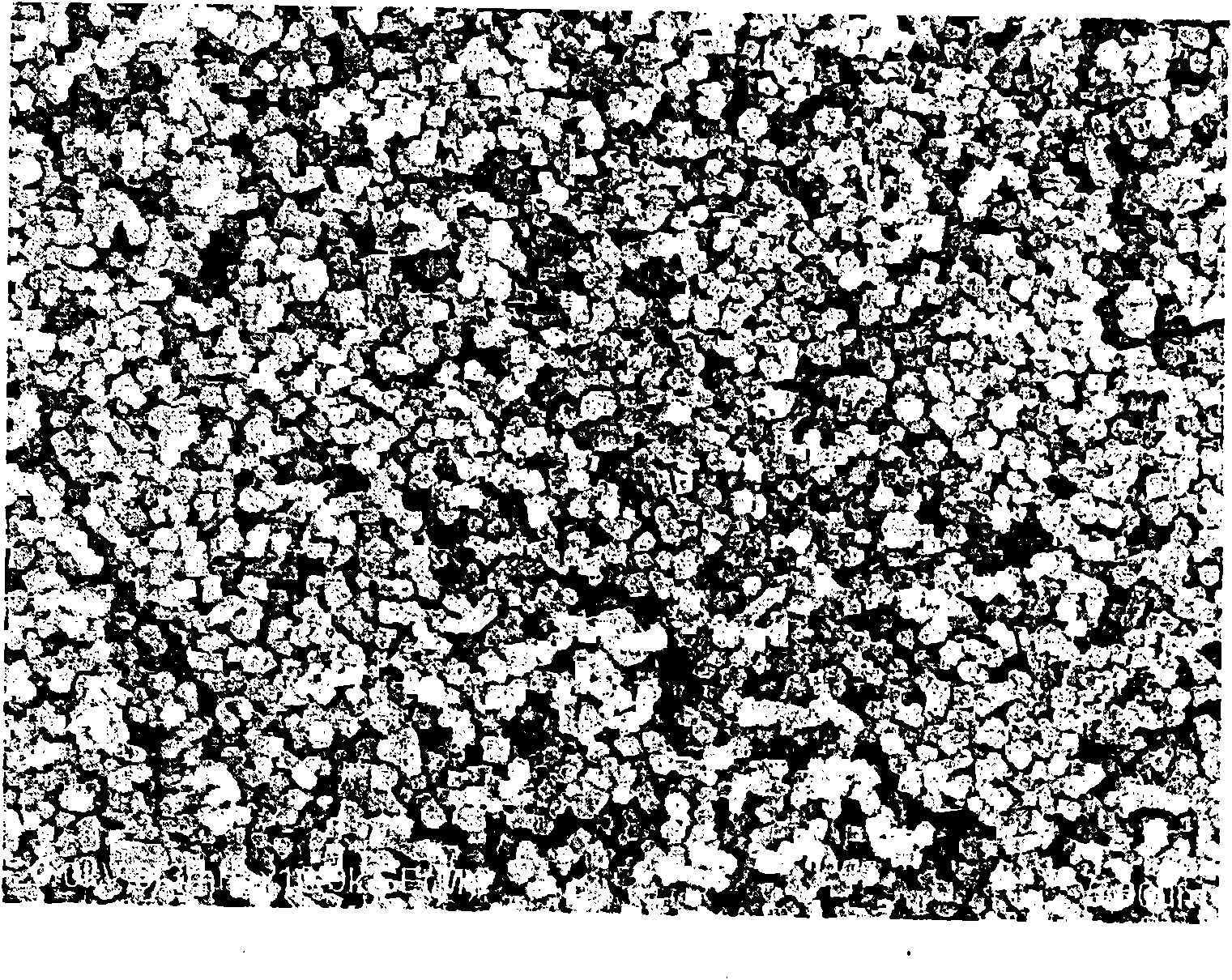

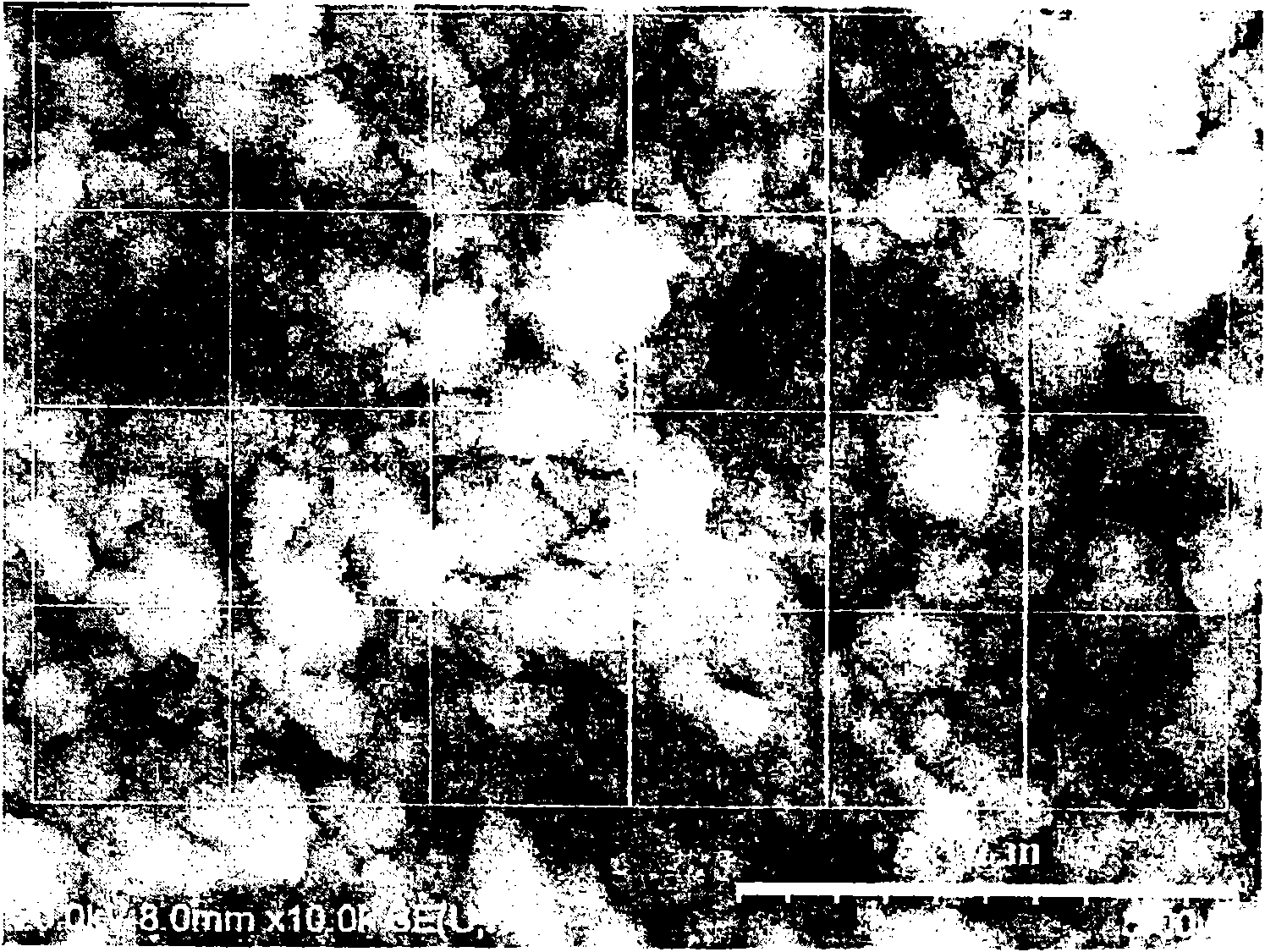

[0134] exist figure 2 The secondary electron image of the iron feedstock used here is represented in , in image 3 The reflection electron images of the obtained precursors are shown in . The average primary particle diameter of the iron raw material used was 200 nm. exist figure 2 24 squares of 2 μm × 2 μm were drawn on the reflection electron image of , and i...

Embodiment 2、3、8

[0139] Experiments were performed with the contents described in Table 2. The parts not described were carried out in the same manner as in Example 1. However, a predetermined amount of carbon-containing additives is blended in the dry ball mill after the second step. Table 3 shows the powder properties of the obtained lithium iron phosphate particles having an olivine structure. In this fine powder having an olivine structure, as in Example 1, except for the composition ratio of Li, Fe, P and the additive element C, the composition ratios of all additive elements and Fe were consistent within a measurement error range of 3%.

Embodiment 4、5、7

[0141] After mixing a predetermined amount of main raw materials in a wet (water solvent) ball mill to obtain 150 g of lithium iron phosphate particle powder, it was dried at 70° C. for 12 hours. Using Li as the main raw material containing lithium and phosphorus 3 PO 4 and H 3 PO 4 (first process).

[0142] At 5mmΦZrO 2 The dry product and a predetermined amount of carbon-containing additives were pulverized in a dry ball mill for 24 hours (step A, second step), and calcined at 400° C. for 2 hours in a nitrogen atmosphere (third step). After crushing and mixing with a dry ball mill, heat treatment was performed again at 650° C. under a nitrogen atmosphere for 2 hours (operation A).

[0143] Table 3 shows the powder properties of the obtained lithium iron phosphate particles having an olivine structure. In this fine powder having an olivine structure, as in Example 1, except for the composition ratio of Li, Fe, P and the additive element C, the composition ratios of all ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com