Method for forming inner ribs of plastic extrusion sections quickly and extrusion die head thereof

A technology for extruding dies and extruding profiles, which is applied in the field of rapid prototyping of plastic extruded profiles and extrusion dies, which can solve the problems of wasting raw materials and increasing production costs, and achieves the improvement of profile quality and reduction of raw materials Loss and bending prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

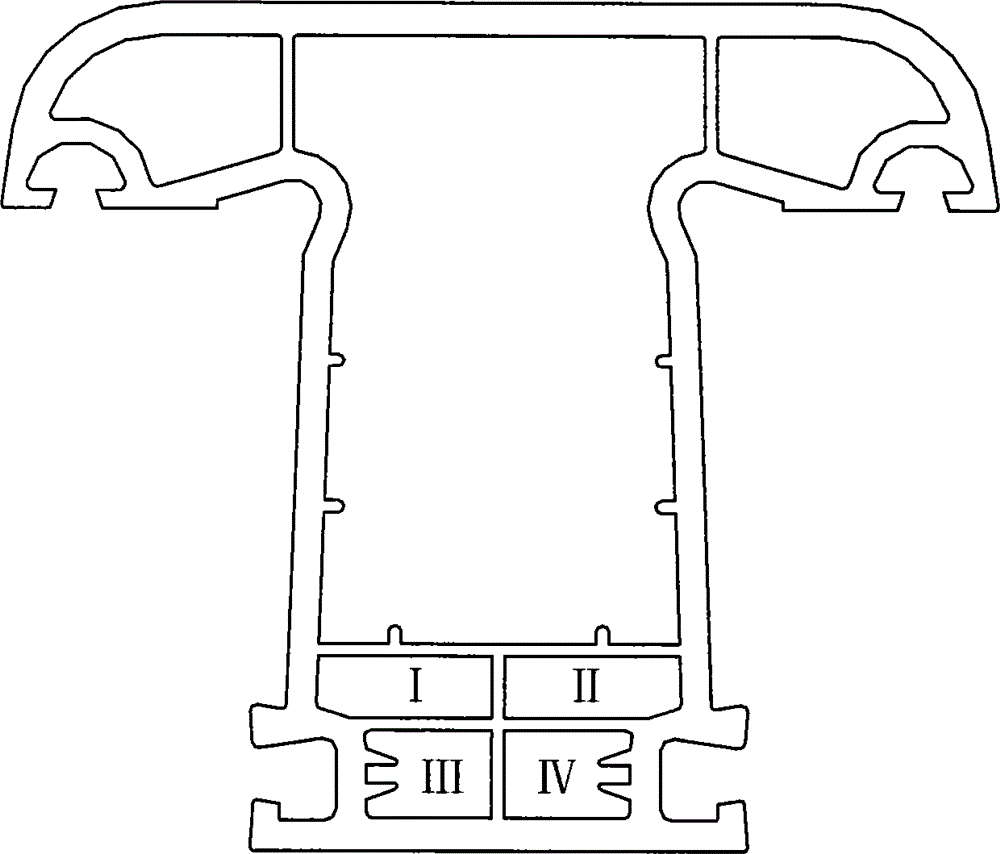

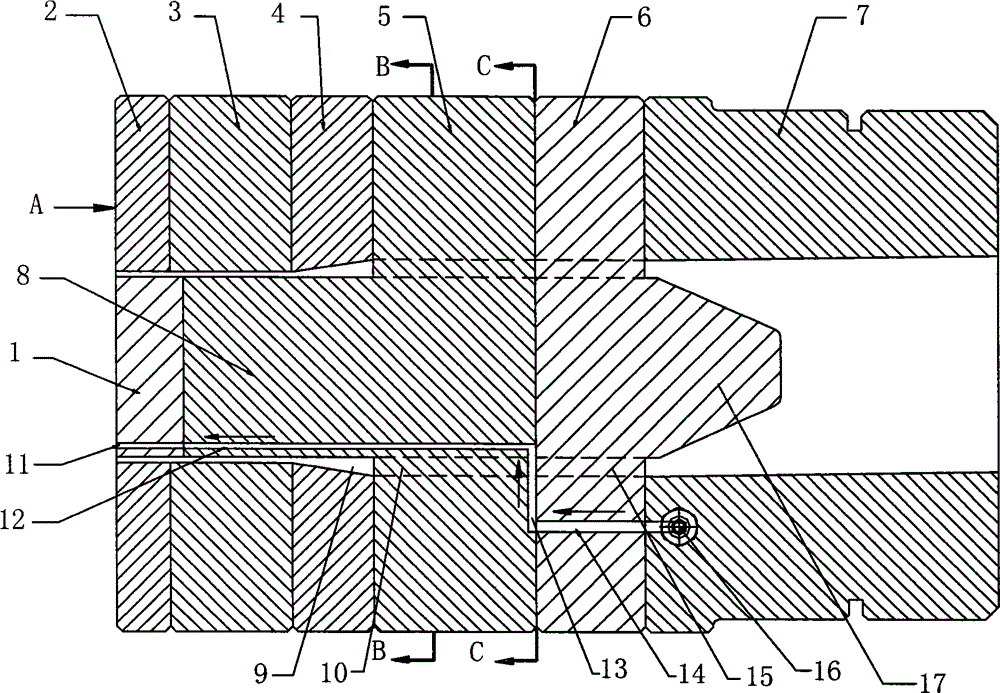

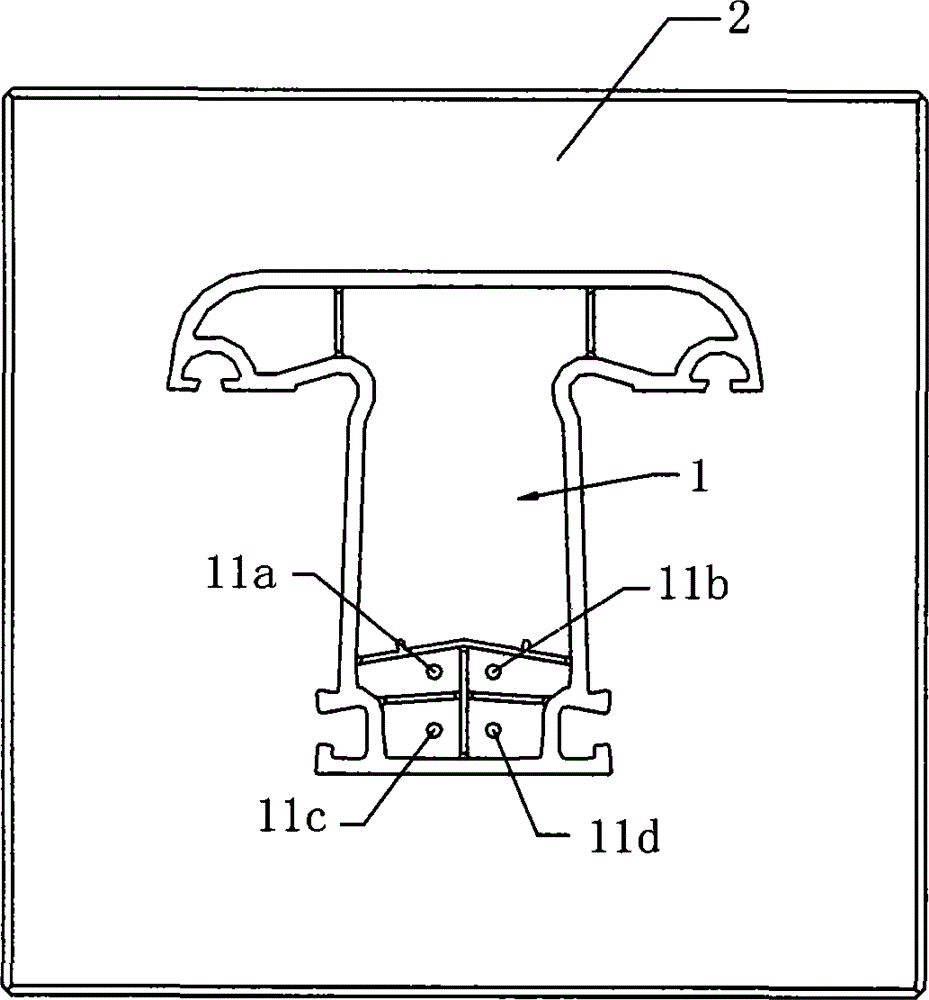

[0016] Extrusion die such as figure 2 As shown, it usually includes machine neck 7, transition plate 6, bracket plate 5, compression plate 4, preformed plate 3, forming plate 2 and insert 1, and splitter cone 17 is integrated with transition plate 6 through connecting rib 15 , the core 8 is integrated with the support plate 5 through the connecting rib 10, and the insert 1 is fixed on the core 8 by screws. Extrusion die head of the present invention has vent hole 11 and airflow passage 12 respectively on insert 1 and core 8, has the lateral passage 13 that communicates with airflow passage 12 on support plate 5, and air inlet 16 is located at On the machine neck 7 , the machine neck 7 and the transition plate 6 are provided with an air intake channel 14 communicating with the side channel 13 . The distribution of vent holes 11 on the insert 1 is as follows image 3 As shown, four air vents 11a-d are respectively opened on the insert 1 corresponding to the four inner cavitie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com