Garden shredder

A pulverizer and gardening technology, applied in grain processing and other directions, can solve the problems of troublesome disassembly of pulverizers, high cost, and increase labor intensity of users, and achieve the effect of reducing use and maintenance costs and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

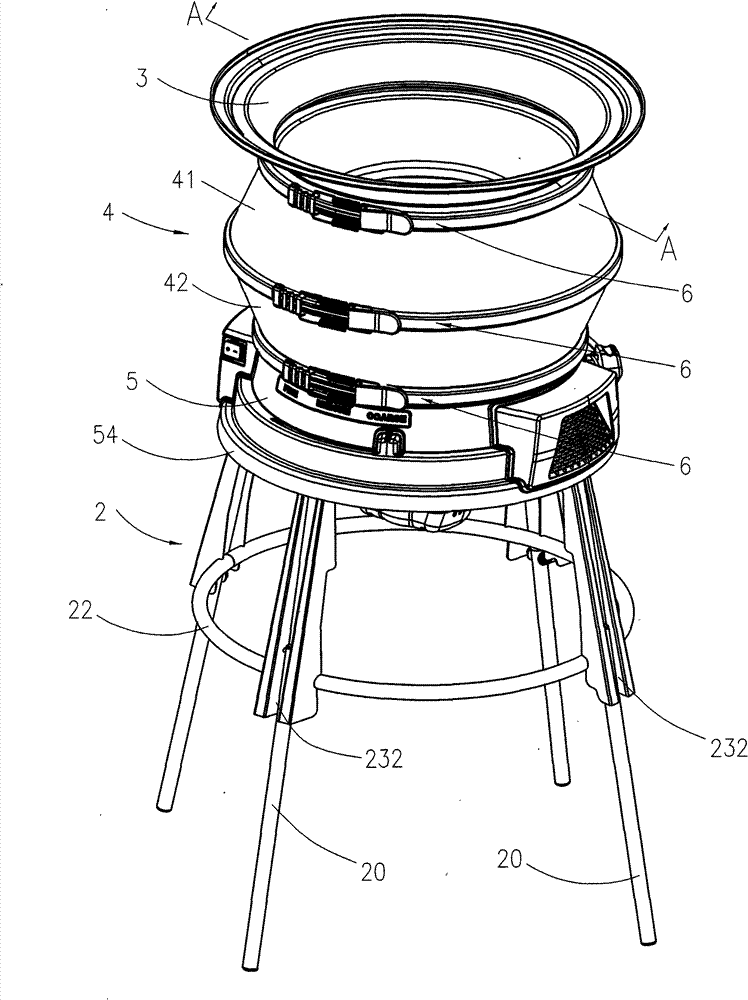

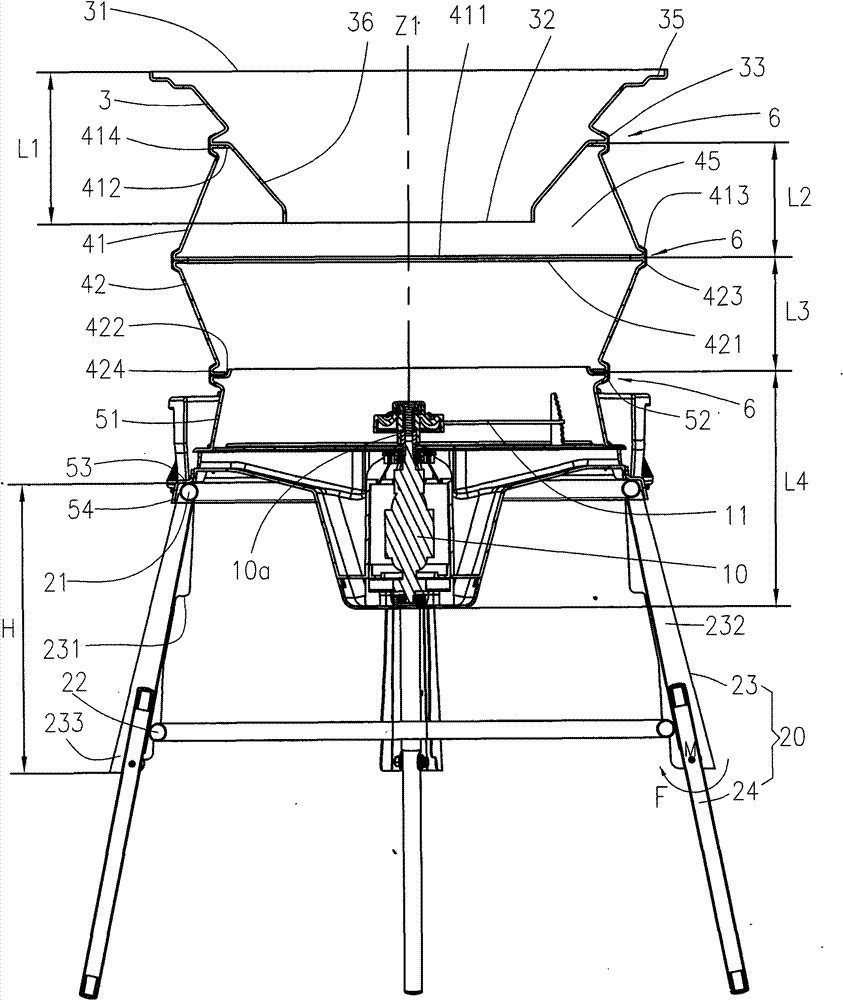

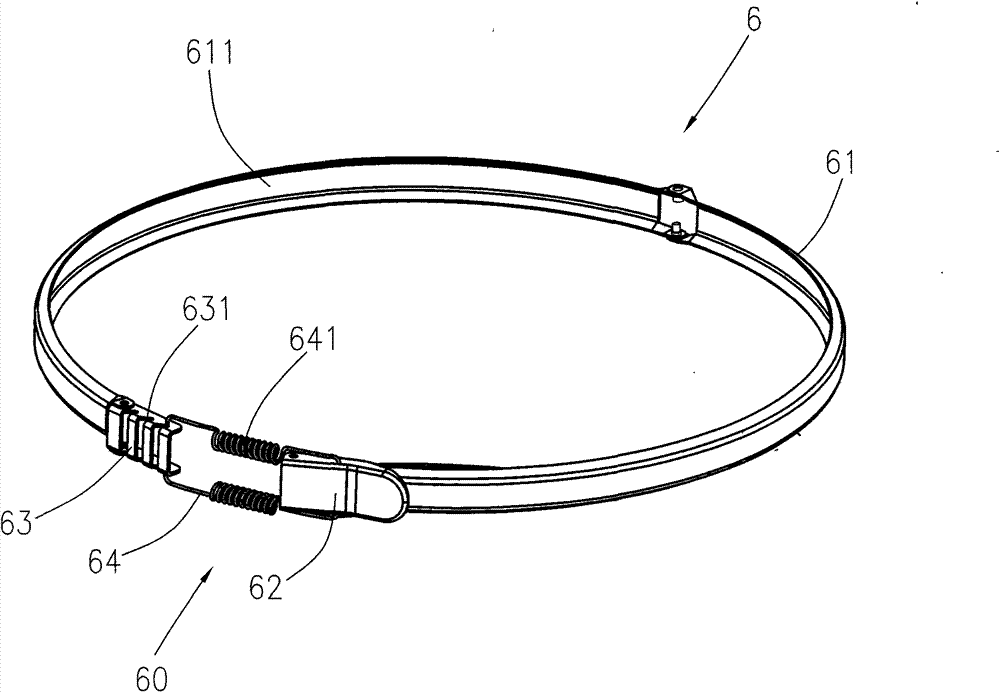

[0050] Such as figure 1As shown, a garden shredder is used for cutting and shredding garbage such as leaves, grass stalks and other garden sundries. The horticultural pulverizer includes a main body 5, a bracket assembly 2 for supporting the main body 5, and a receiving container 4 detachably fitted on the main body 5, wherein the receiving container 4 includes an upper material bucket 41 and a lower material bucket 42, And the hopper 3 that is connected to the upper bucket 41. Wherein the lower material barrel 42 and the main body 5, the upper material barrel 41 and the lower material barrel 42, and the upper material barrel 41 and the guide hopper 3 are detachably connected together through the quick locking device 6 respectively.

[0051] Such as figure 2 As shown, the guide hopper 3 is a conical body, which is provided with an upper opening 31 and a lower opening 32. The diameter of the upper opening 31 is greater than the diameter of the lower opening 32. The edge 35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com