Elevator device and cable special for elevator

A technology for elevators and cables, which is applied in the direction of textile cables, elevators in buildings, transportation and packaging, etc. It can solve the problems of reducing fatigue life and increasing the bending stress of main cables, so as to achieve the effect of improving life and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

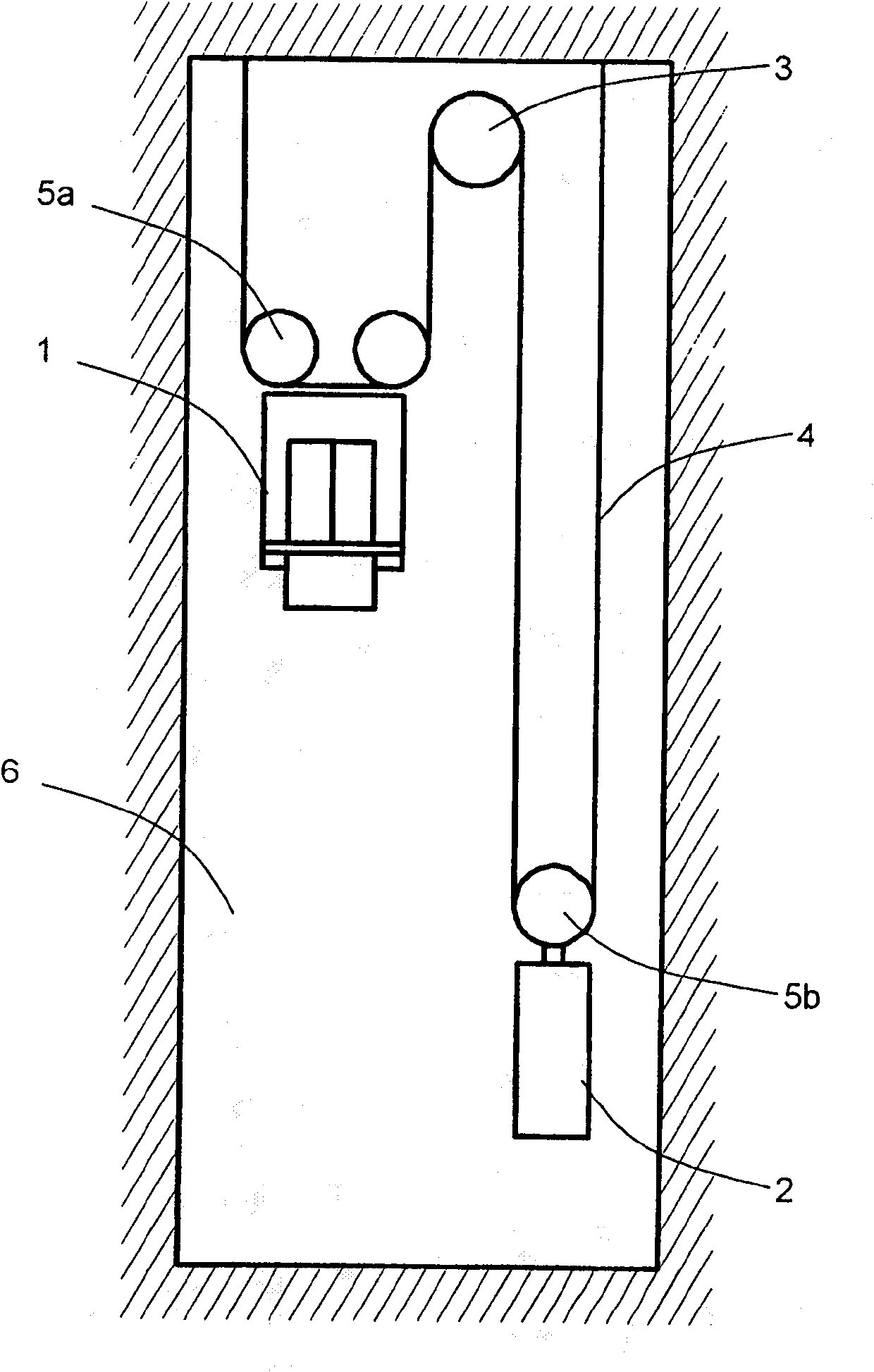

[0039] Hereinafter, an embodiment of an elevator apparatus using the resin-coated cable according to the present invention for the main cable will be described with reference to the drawings.

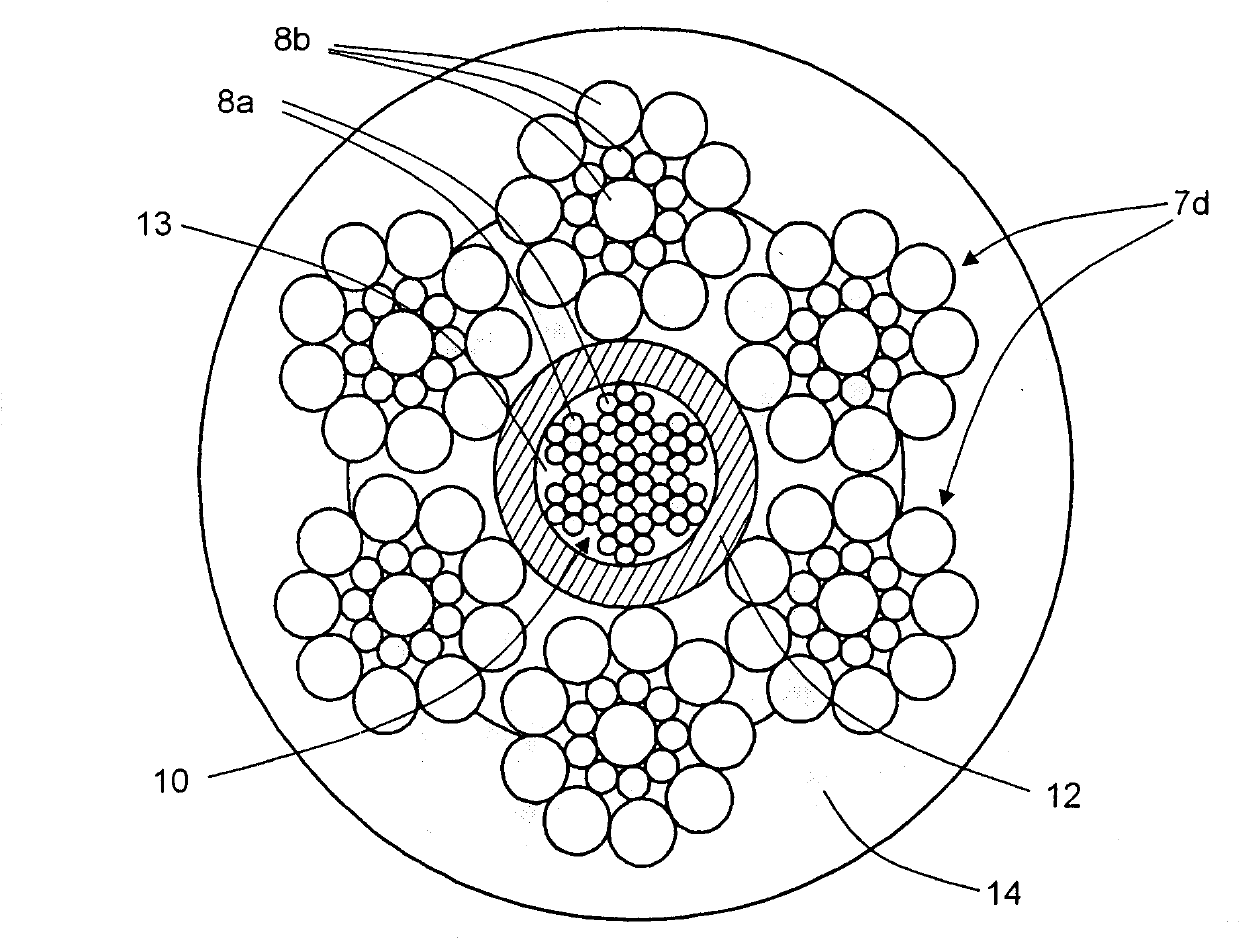

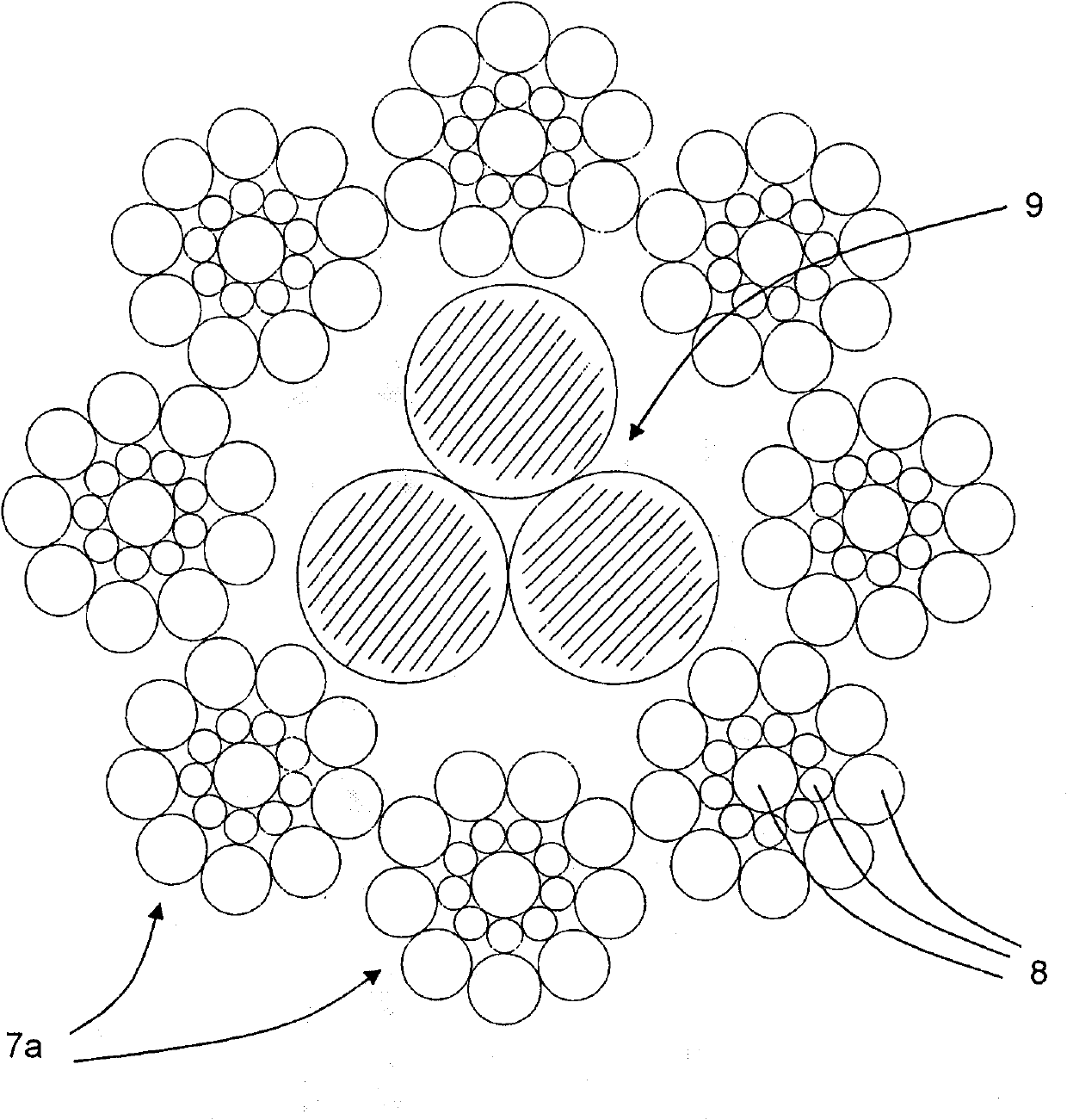

[0040] figure 1 An example of the main rope in the elevator apparatus of the present invention is shown. in figure 1 Here, the steel core 10 is formed by twisting a plurality of steel wires 8a. The braid 12 is configured to braid synthetic fibers into a cylindrical shape and cover the outer circumference of the steel core 10. The strand 7d is formed by twisting multiple steel wires 8b, multiple (such as figure 1 The example shown is 6) strands 7d are arranged to surround the outer side of the core wire covering material 12. An outer covering layer 14 made of polyurethane resin covering the entire outer circumference of the plurality of strands 7d to cover the surface of the cable is formed. The core wire covering material 12 is filled with a solid lubricant 13.

[0041] The core wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap