Iron group metal material after black surface treatment and manufacturing method thereof

A metal material and surface treatment technology, applied in the direction of metal material coating process, etc., can solve the problems of high cost and economy, chromium-free, product corrosion resistance can not be said to have sufficient performance, etc., to achieve excellent corrosion resistance and sliding performance The effect of excellent and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

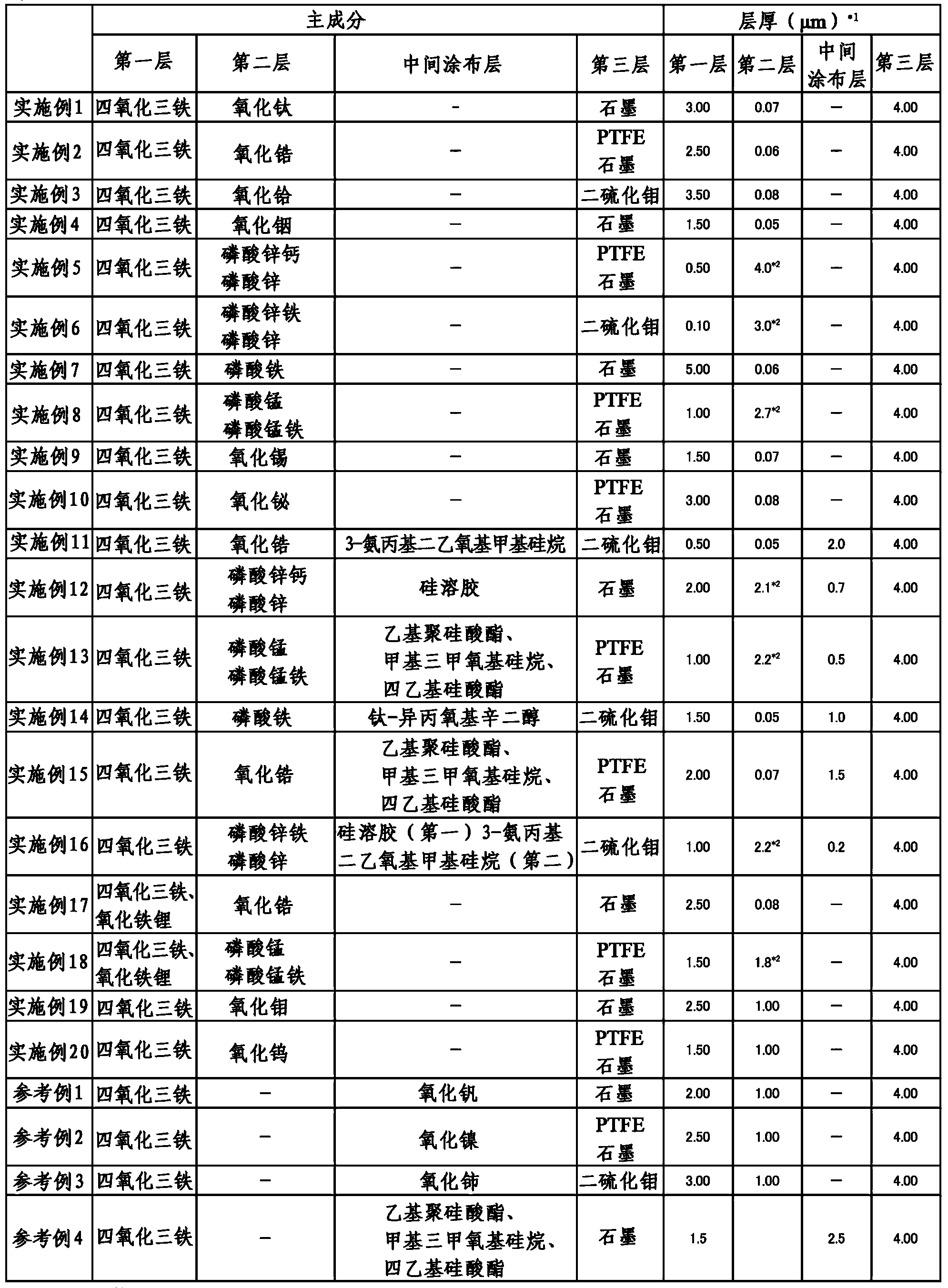

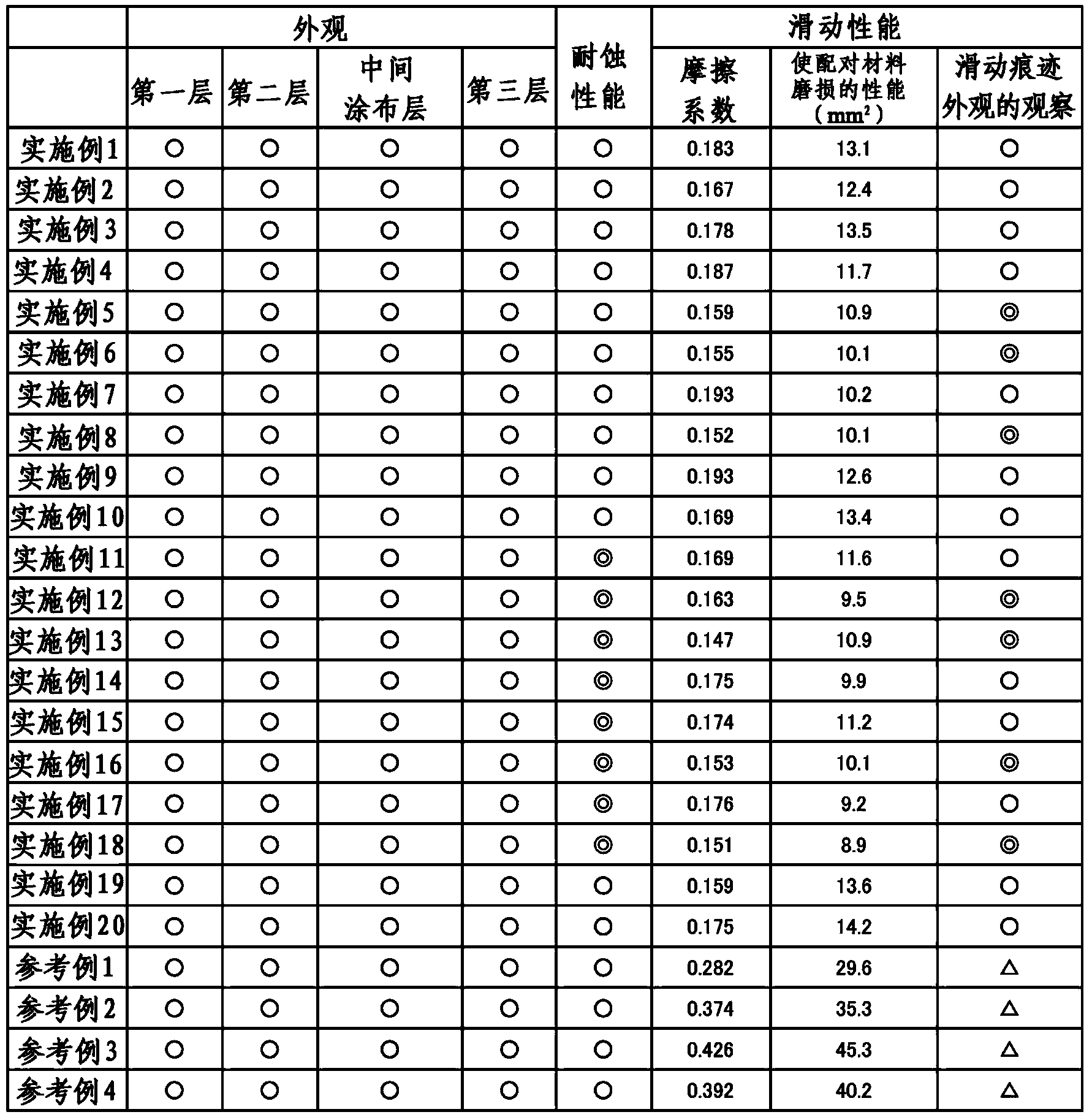

Examples

Embodiment 1~10 and 17~20

[0092] Embodiments 1-10 and 17-20, comparative examples 6-7 are implemented according to the following procedures.

[0093] Alkaline degreasing → washing with water → forming the first layer → washing with water → forming the second layer → washing with water → drying → forming the third layer → baking

Embodiment 11~16

[0094] Embodiments 11-16 are implemented according to the following procedures.

[0095] Alkaline degreasing→Washing→Forming the first layer→Washing→Forming the second layer→Washing→Drying→Forming the middle coating layer→Drying, baking→Forming the third layer→Baking

[0096] Reference examples 1-4 are implemented according to the following procedures.

[0097] Alkaline degreasing→Water washing→Forming the first layer→Washing→Drying→Forming the middle coating layer→Drying, baking→Forming the third layer→Baking

Embodiment 1

[0135] Dilute "Palburak A" manufactured by Nippon Pakase Seiki Co., Ltd. with tap water to a concentration of 80.5% by mass, use the diluted solution as a blackening agent, heat to 148°C, and degrease the iron-based The metal material is immersed for 60 minutes, and the first layer mainly composed of ferric iron tetroxide is formed on the surface of the iron-based metal material after the alkali degreasing treatment.

[0136] Use titanium hydrofluoride reagent, nitric acid reagent and hydrofluoric acid reagent to prepare an acidic chemical conversion treatment solution with a titanium concentration of 2000 mg / L, a nitric acid concentration of 10000 mg / L, and a fluorine concentration of 7 mg / L as free fluorine. Then, the chemical conversion treatment liquid is heated to 50° C., and the pH is adjusted to 3.0 with an ammonia water reagent. In the adjusted chemical conversion treatment liquid, the iron-based metal material formed on the first layer is immersed for 300 seconds to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com