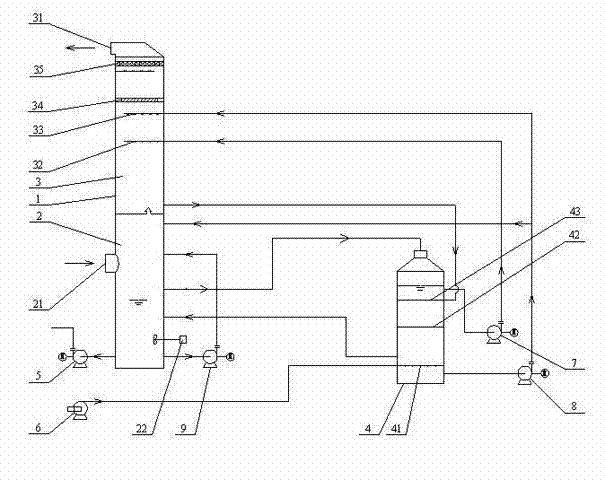

Double-tower ammonia method desulfuration device and process

An ammonia desulfurization and desulfurization absorption tower technology, applied in the field of environmental protection equipment, can solve the problems of low oxidation efficiency, slow oxidation reaction speed, and uneven oxygen concentration, and achieve the effects of high absorption efficiency, reduced decomposition, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Examples are as follows: the flue gas from the boiler temperature of 120 ° C is 100 × 10 4 N m 3 / h, SO in flue gas 2 The concentration is 2000ppm. After the flue gas enters the desulfurization absorption tower, it contacts with the absorption liquid, begins to cool down, and a part of the reaction occurs; the flue gas rises further, enters the spray absorption section of the upper section from the cooling and concentration section, and the flue gas temperature in the spray absorption section When the temperature drops to about 60℃~70℃, it reacts with ammonium sulfite in the absorption liquid to generate ammonium bisulfite; the flue gas further rises through the first-level spray layer and continues to react, and the SO in the flue gas 2 Further removal; when passing through the second spray layer, the SO in the flue gas 2 The removal rate has basically reached the design requirements; the flue gas continues to pass through the packing layer and the demisting area, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com