Method for controlling feed amount in dry process acetylene production

A dry-process acetylene and control method technology, applied in the direction of feeding devices, chemical instruments and methods, hydrocarbons, etc., can solve problems such as high moisture content of carbide slag, high product consumption, and difficulty in comprehensive utilization of carbide slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

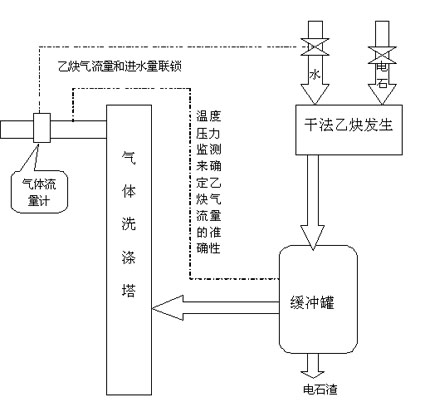

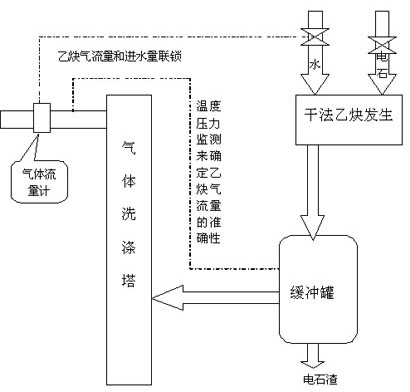

[0019] according to figure 1 The process description of the process diagram of the precise control of the dry acetylene feed amount:

[0020] 1. Input the set value of acetylene gas flow and the actual gas production of this batch of calcium carbide into the microcomputer control system, and the microcomputer control system calculates the feeding amount of calcium carbide, and controls the calcium carbide feeding device to feed.

[0021] 2. The microcomputer control system calculates the set value of process water consumption through the gas generation and feeding volume of calcium carbide.

[0022] 3. The microcomputer control system calculates the standard mixed gas flow rate according to the pressure, temperature, flow rate and other parameters of the buffer tank and washing tower, and compares it with the set value of the acetylene gas flow rate to adjust the process water flow rate.

[0023] 4. The microcomputer control system calculates the acetylene flow value and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com