Preparation method of tamibarotene stable crystals

A tamibarotene and crystallization technology, which is applied in the field of compound crystal preparation, can solve the problems of strong irritating odor, easy residual solvent, strong corrosiveness, etc., and achieves a solution with no solvent residue, low reagent toxicity, and avoidance of degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

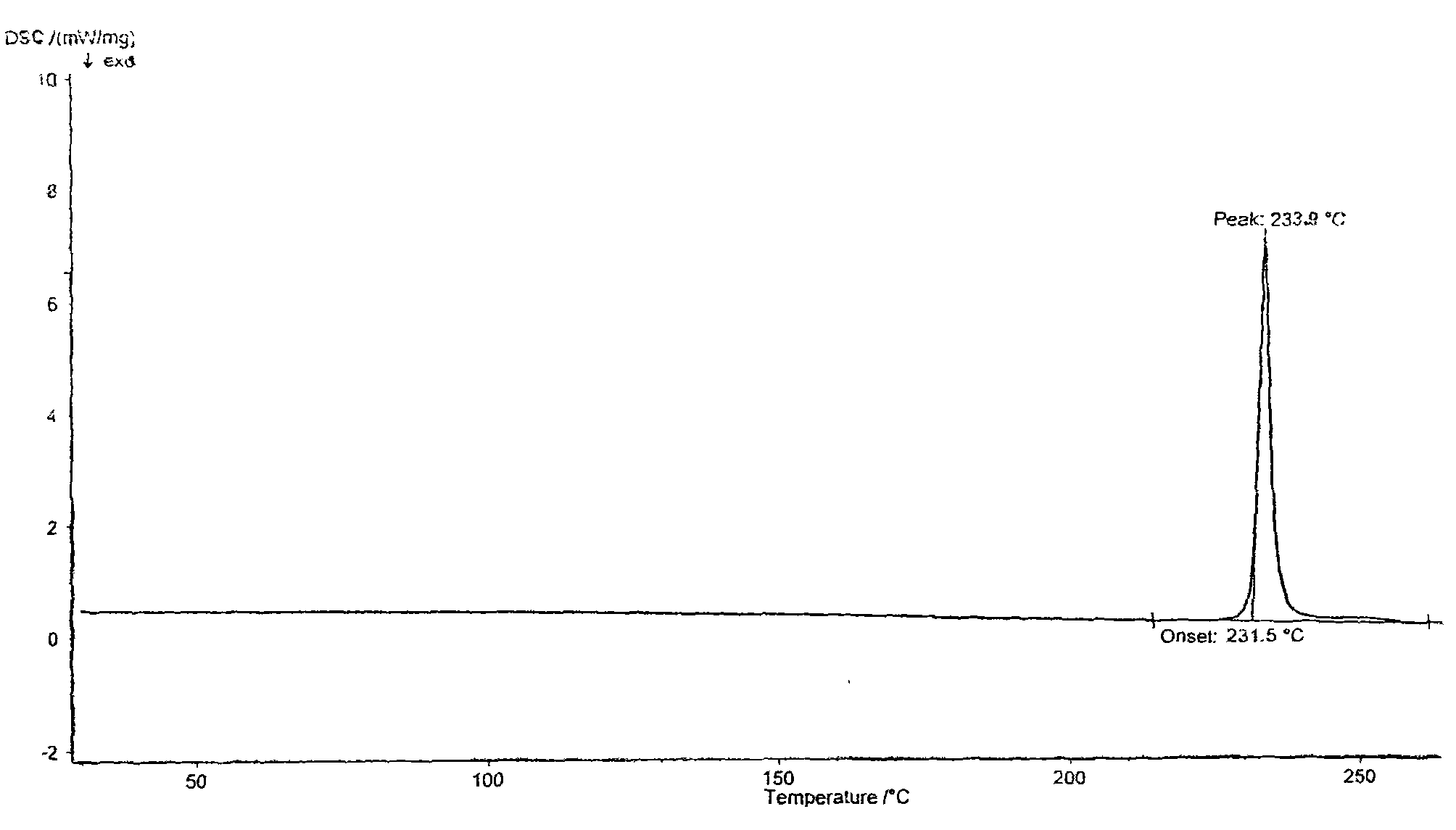

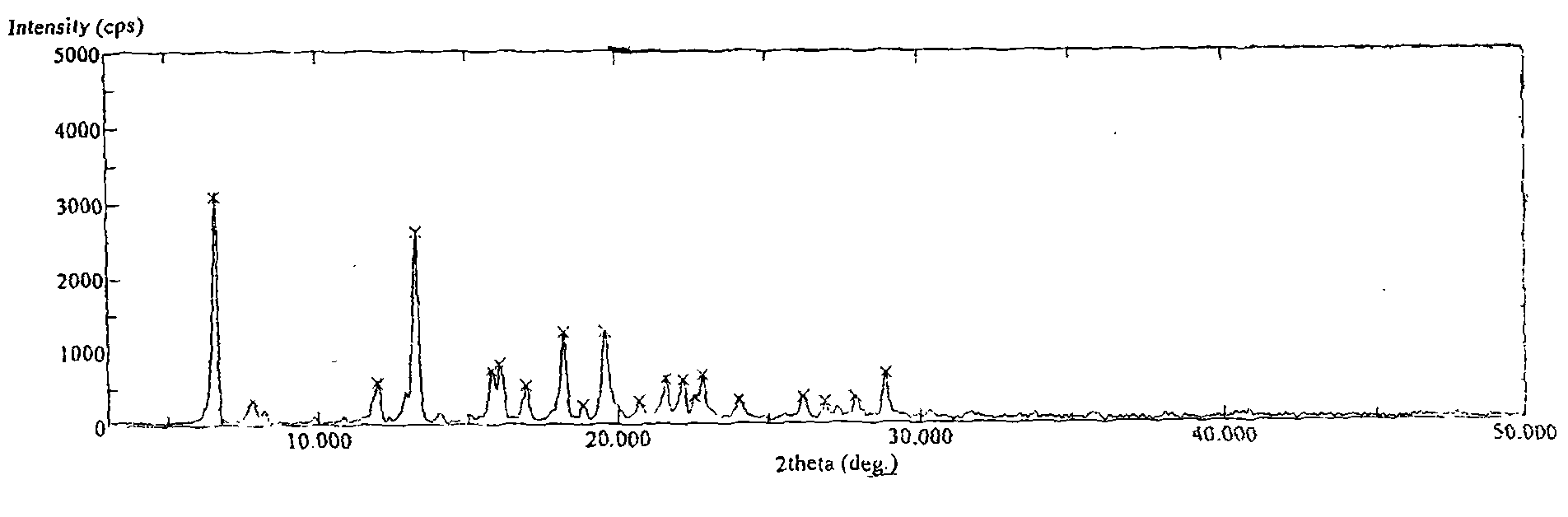

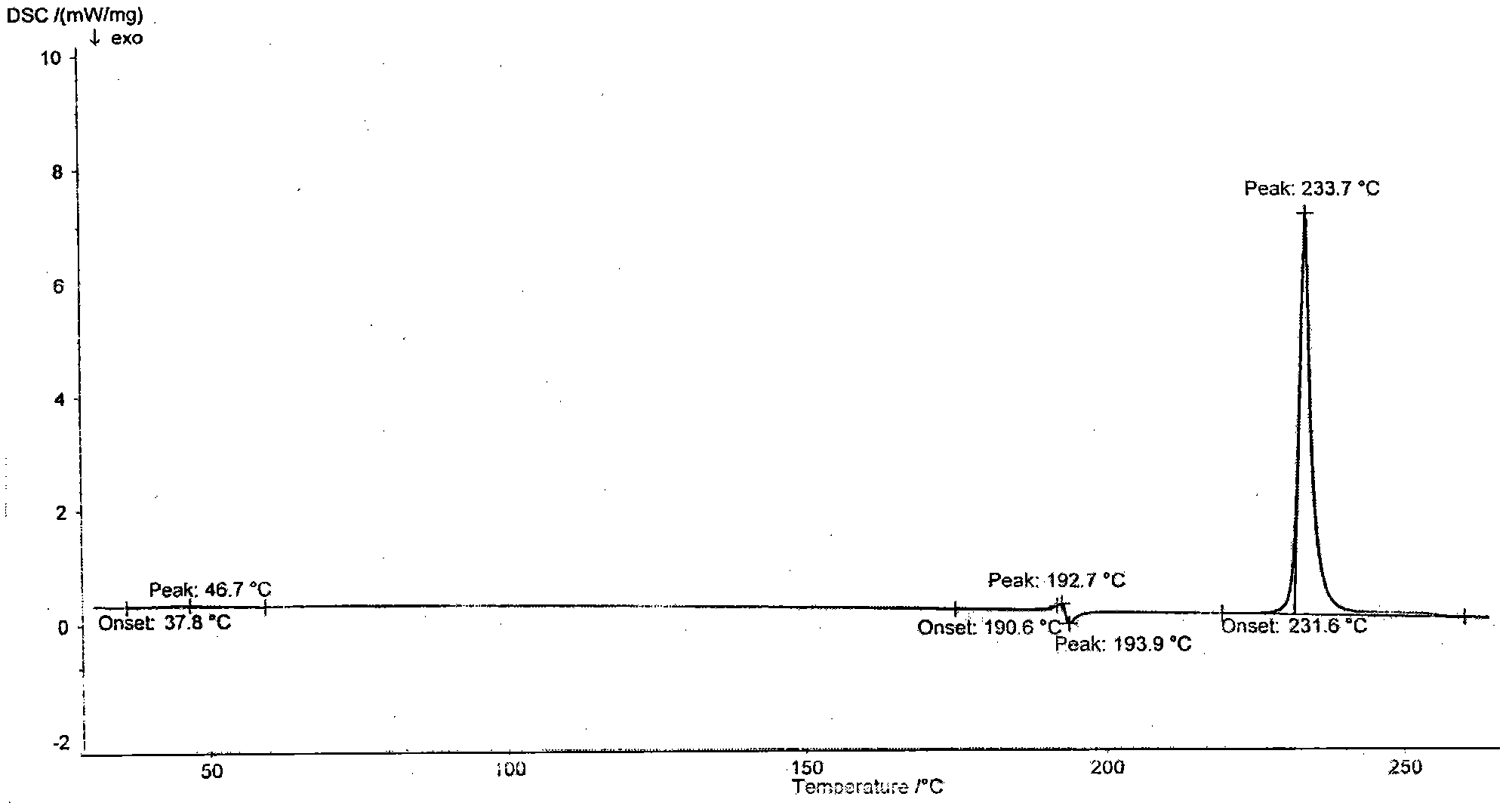

[0020] Add 2 g of tamibarotene into 60 ml of methanol-20 ml of water mixed solvent, reflux for 0.5 hours, let it stand and cool to room temperature, fully analyze the crystallization, filter and dry the crystals in vacuum at 80°C for 4 hours, and crush the dried needle crystals into In fine powder form, vacuum-dried at 140° C. for 24 hours to obtain 1.85 g of Tamibarotene crystals. The melting point measured by capillary method is 233-234°C. The purity detected by HPLC was 99.83%. Simple impurities are all below 0.1%.

Embodiment 2

[0022] Add 2 g of tamibarotene into 40 ml of methanol-20 ml of water mixed solvent, reflux for 0.5 hours, let it stand to cool to room temperature, fully analyze the crystallization, filter and dry the crystals in vacuum at 80°C for 4 hours, and crush the dried needle crystals into In fine powder form, vacuum-dried at 160° C. for 15 hours to obtain 1.79 g of Tamibarotene crystals. The melting point measured by capillary method is 233-234°C. The purity by HPLC was 99.85%. Simple impurities are all below 0.1%.

Embodiment 3

[0024] Add 2 g of tamibarotene into 40 ml of methanol-10 ml of water mixed solvent, reflux for 0.5 hours, let it stand and cool to room temperature, fully analyze the crystallization, filter and dry the crystals in vacuum at 80°C for 4 hours, and crush the dried needle crystals into In fine powder form, vacuum-dried at 170° C. for 10 hours to obtain 1.80 g of Tamibarotene crystals. The melting point measured by capillary method is 233-234°C. The purity detected by HPLC was 99.80%. Simple impurities are all below 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com