Cooling structure of electronic equipment

A technology for electronic equipment and cooling structure, which is applied to the structural parts of electrical equipment, cooling/ventilation/heating renovation, electrical components, etc., which can solve the problems of reducing the influence of external environmental factors, failing to obtain heat conduction efficiency, and unable to expect a large scale. , to achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Next, embodiments of the present invention will be described with reference to the drawings.

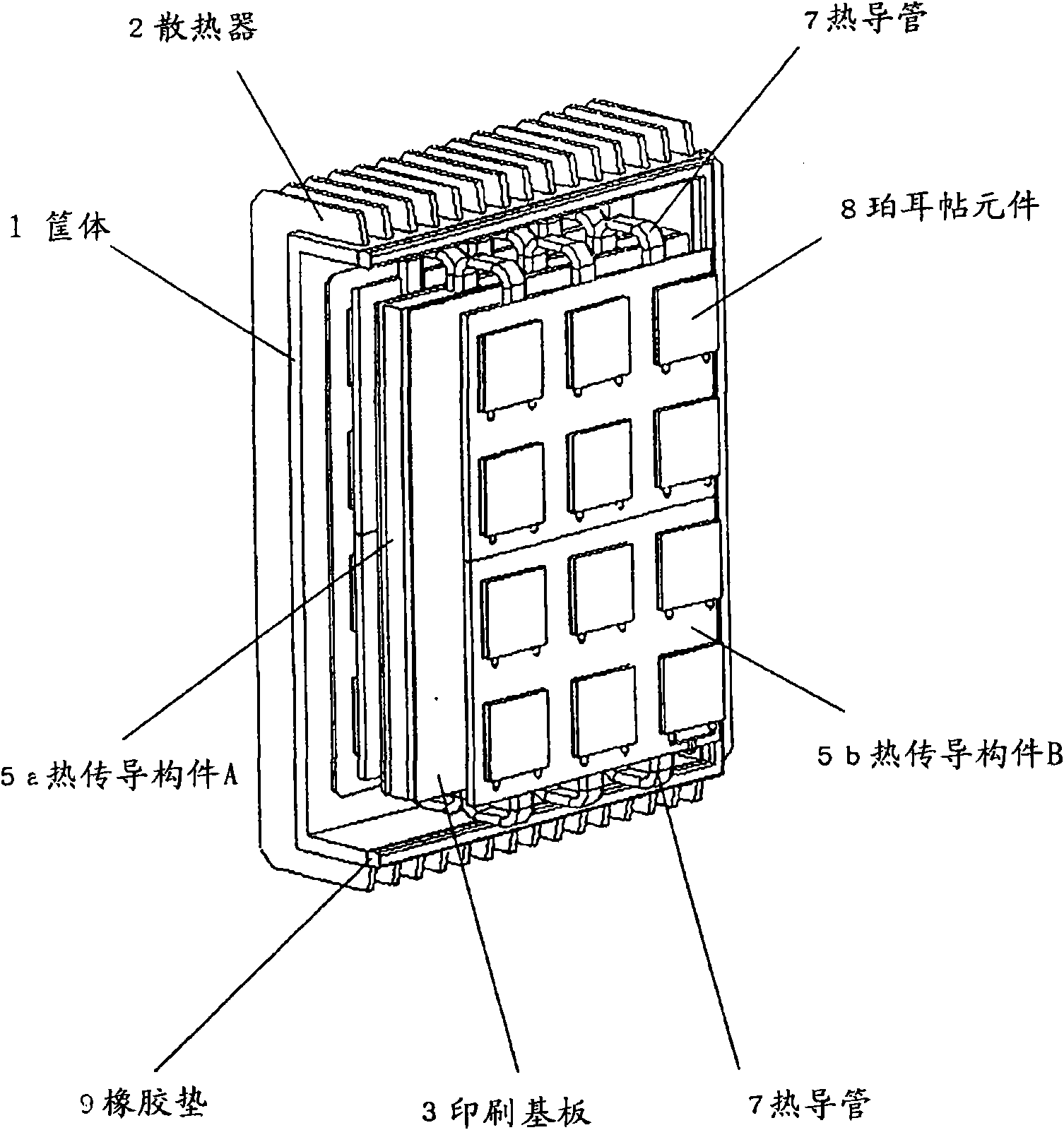

[0058] figure 1 It is a perspective view transparently showing the electronic device of this embodiment.

[0059] This electronic equipment includes: housing 1, radiator 2, printed substrate 3, heat conduction member A5a, heat conduction member B5b, rubber pad 9, heat pipe 7 and Peltier element (heat conduction control member) 8, not shown in the figure Electronic component 4 , control circuit unit 12 , and temperature sensor 13 .

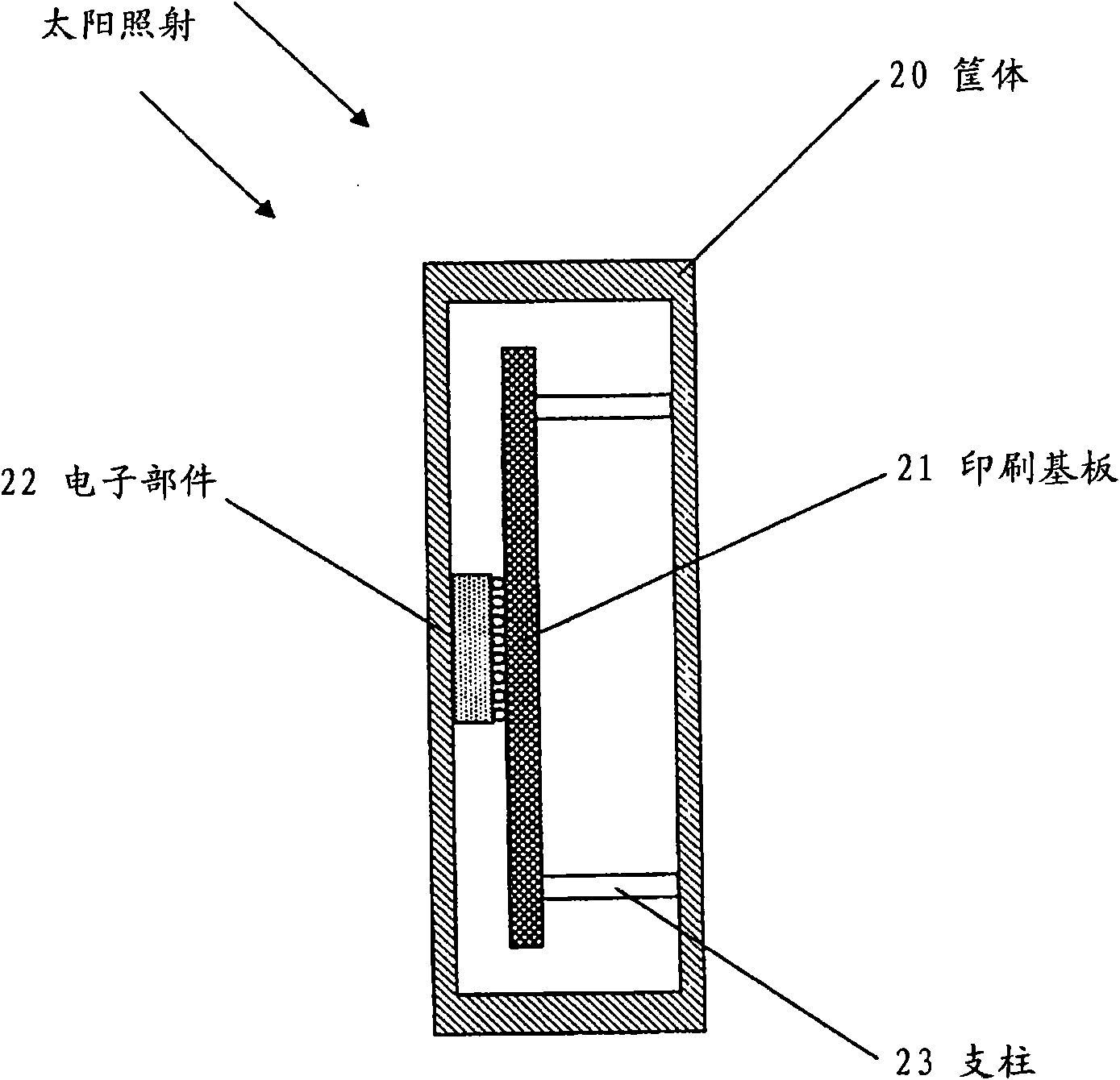

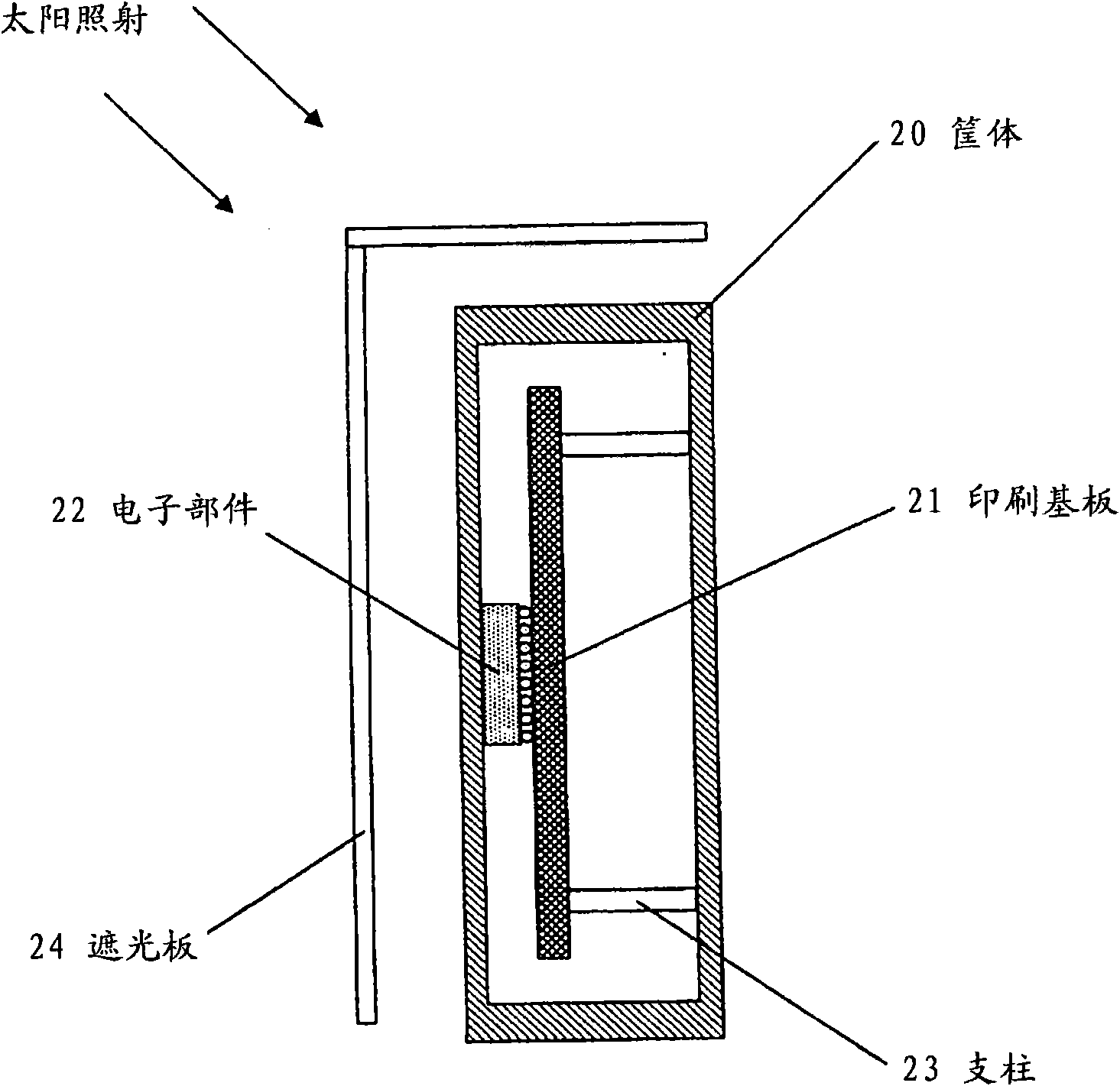

[0060] Figure 6 It is a sectional side view showing the electronic device of this embodiment.

[0061] This electronic device has a housing A1a and a housing B1b, and heat sinks 2 are formed on respective housing surfaces (first surface, second surface) to dissipate heat to the outside atmosphere. The housing A1a and the housing B1b each have sufficient cooling performance and have substantially the same thermal resistance. Moreover, in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com