Method for checking a pressure sensor of a fuel storage device

A pressure sensor, fuel storage technology, applied in measuring devices, measuring fluid pressure, fuel injection control, etc., can solve problems such as customer satisfaction impact, and achieve the effect of simplified analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

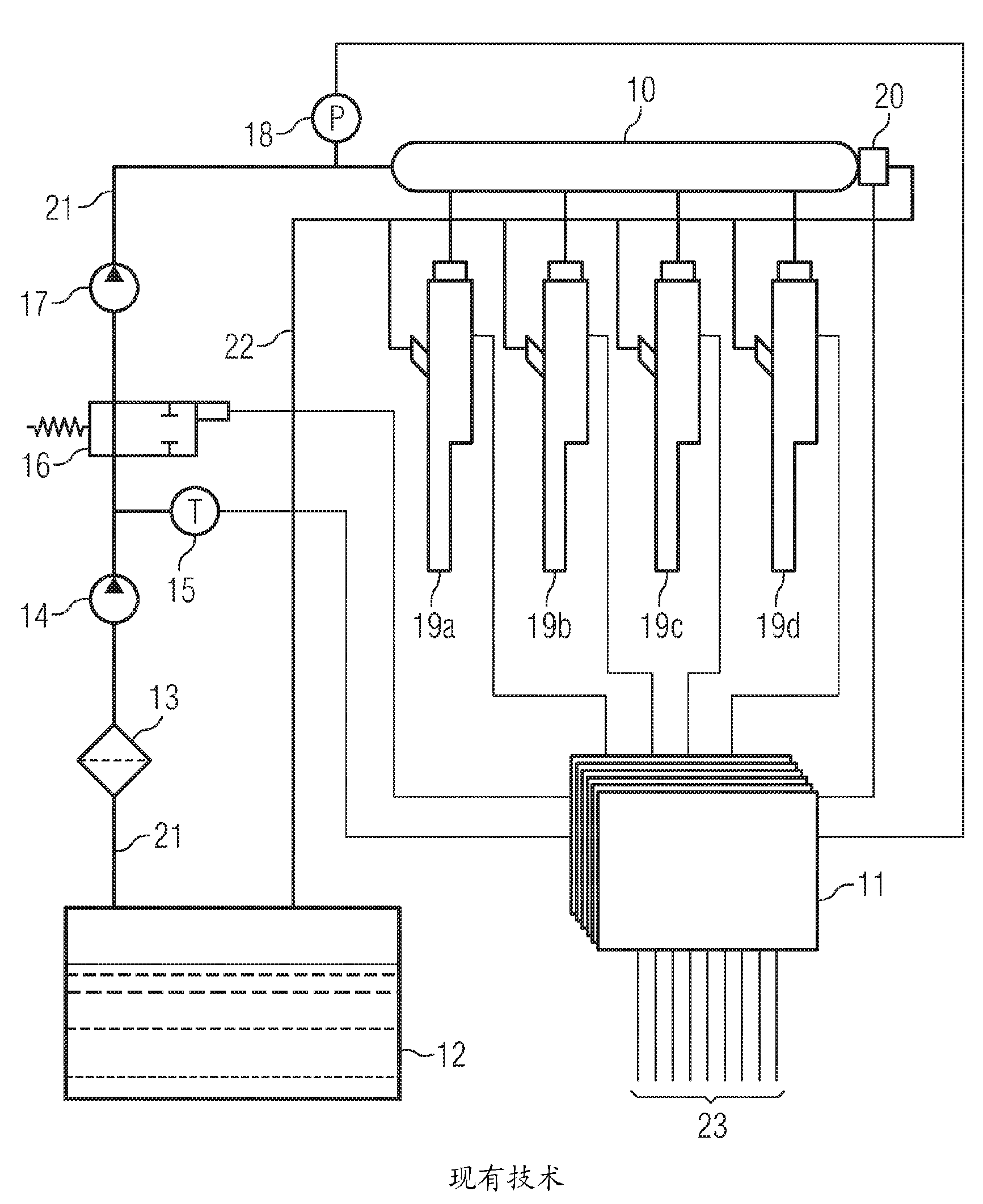

[0024] figure 1 The fuel supply to the internal combustion engine is shown schematically. Here, the fuel is carried in the storage tank 12 of the vehicle. From there, the fuel is sucked in by the low-pressure pump via the fuel filter 13 by means of the delivery line 21 . The quantity supplied to the internal combustion engine in the respective operating state can be influenced by the electromechanical system 11 by means of the regulating valve 16 . The quantity leaving regulating valve 16 is compressed by high-pressure pump 17 and delivered to fuel storage device 10 . In order to measure the pressure flooding in the fuel storage, a pressure measuring device 18 is provided. In this case, the setpoint value of the pressure is determined by the motor control unit 11 as a function of the operating state. If the pressure determined by the sensor 18 is below the target value, the throughput regulator 16 and the high-pressure pump 17 deliver additional fuel to the storage device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com