Novel method and equipment for separating volatilizable material from material by continuous vacuum drying

A vacuum drying and volatile technology, which is applied in the direction of drying solid materials and method combinations to dry solid materials, drying chambers/containers, etc., can solve the problems of large heat loss, increased energy consumption, inconvenient entry and exit of material loading and unloading personnel, etc. Ease of entry and exit, increased heat exposure, faster migration and evaporation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0064] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

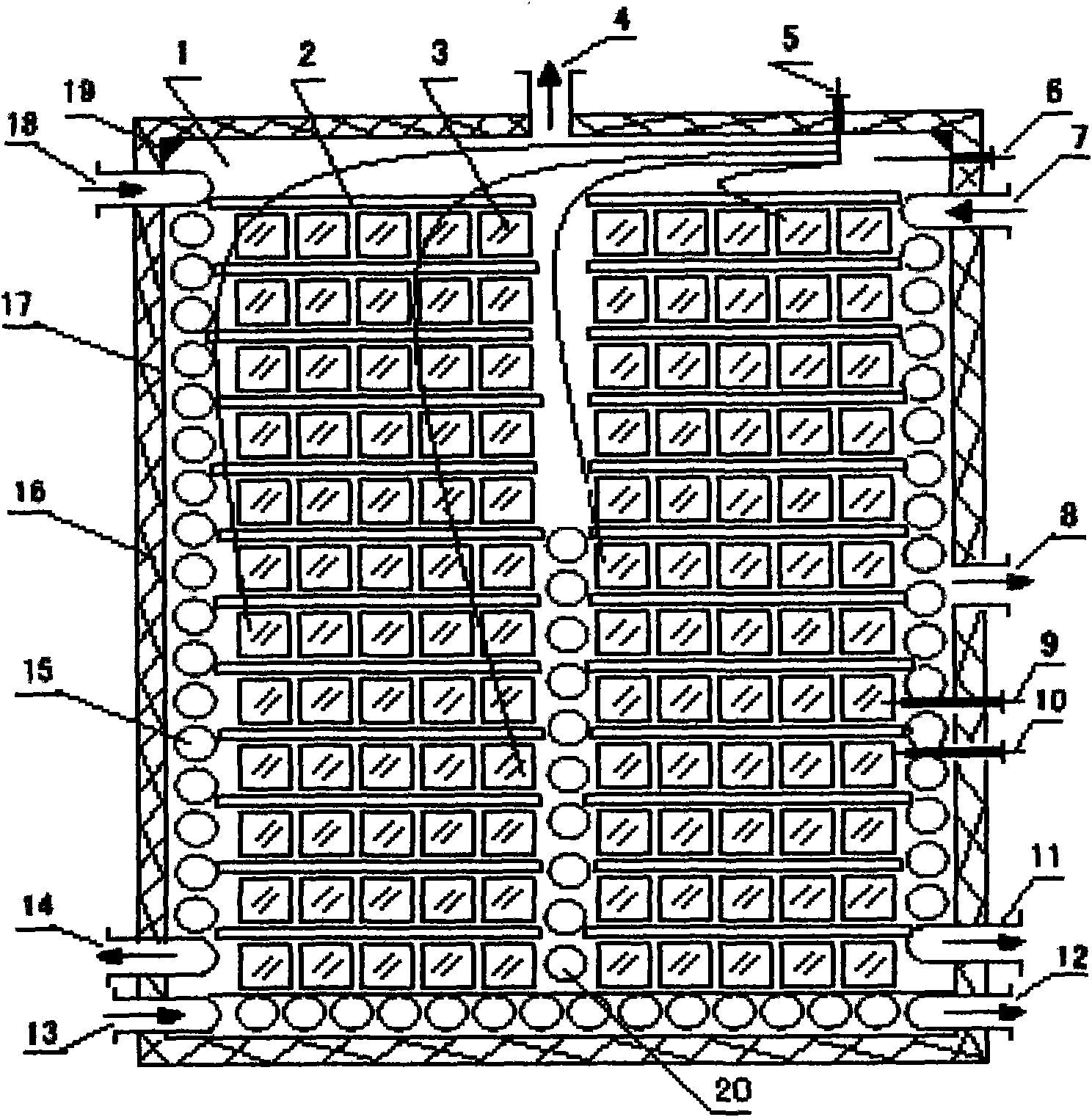

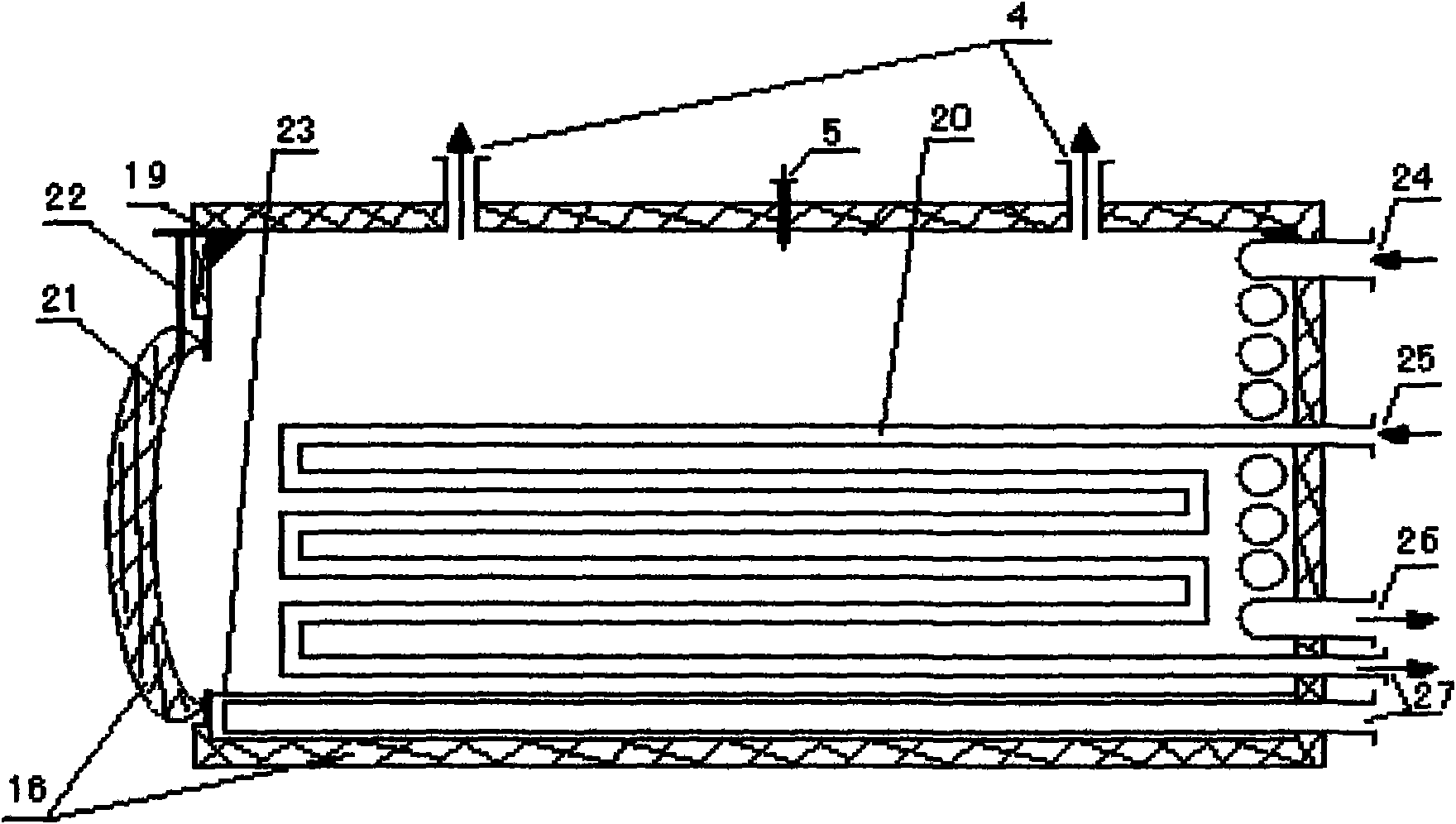

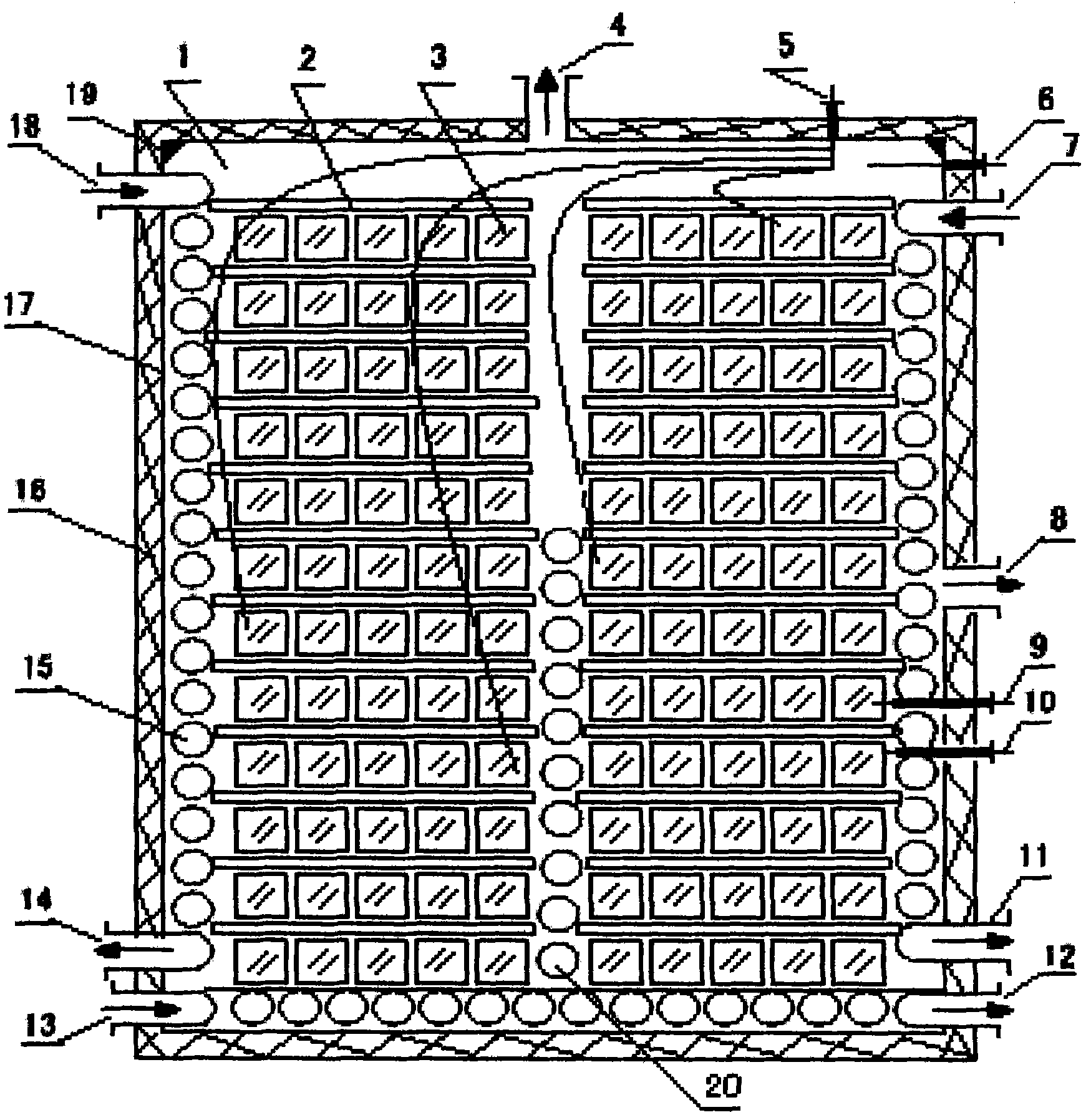

[0065] The schematic diagram of a specific embodiment of the equipment for the novel continuous vacuum drying that detaches material volatiles proposed by the present invention is shown in figure 1 and figure 2 .

[0066] figure 1 A schematic cross-sectional view of the box chamber loaded with materials and gaskets, as shown in the figure: a cube-shaped box chamber 1 is placed between the gasket 2 and the material 3 layers; the top wall of the box has a vacuum port 4, and the side wall has a Vacuum port 8; the top wall of the box body has a probe cable interface 5 for the volatile matter content parameter tester in the material; the side wall of the box body has a chamber 1 internal environment temperature parameter measurement instrument probe interface 6, and material internal temperature parameter measurement Instrument probe interface 9, instru...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap