Method for monitoring impedance of connectors in power battery pack

A power battery pack and internal connection technology, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve problems such as reduced safety and service life, ineffective transmission of nut-type tension, battery rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

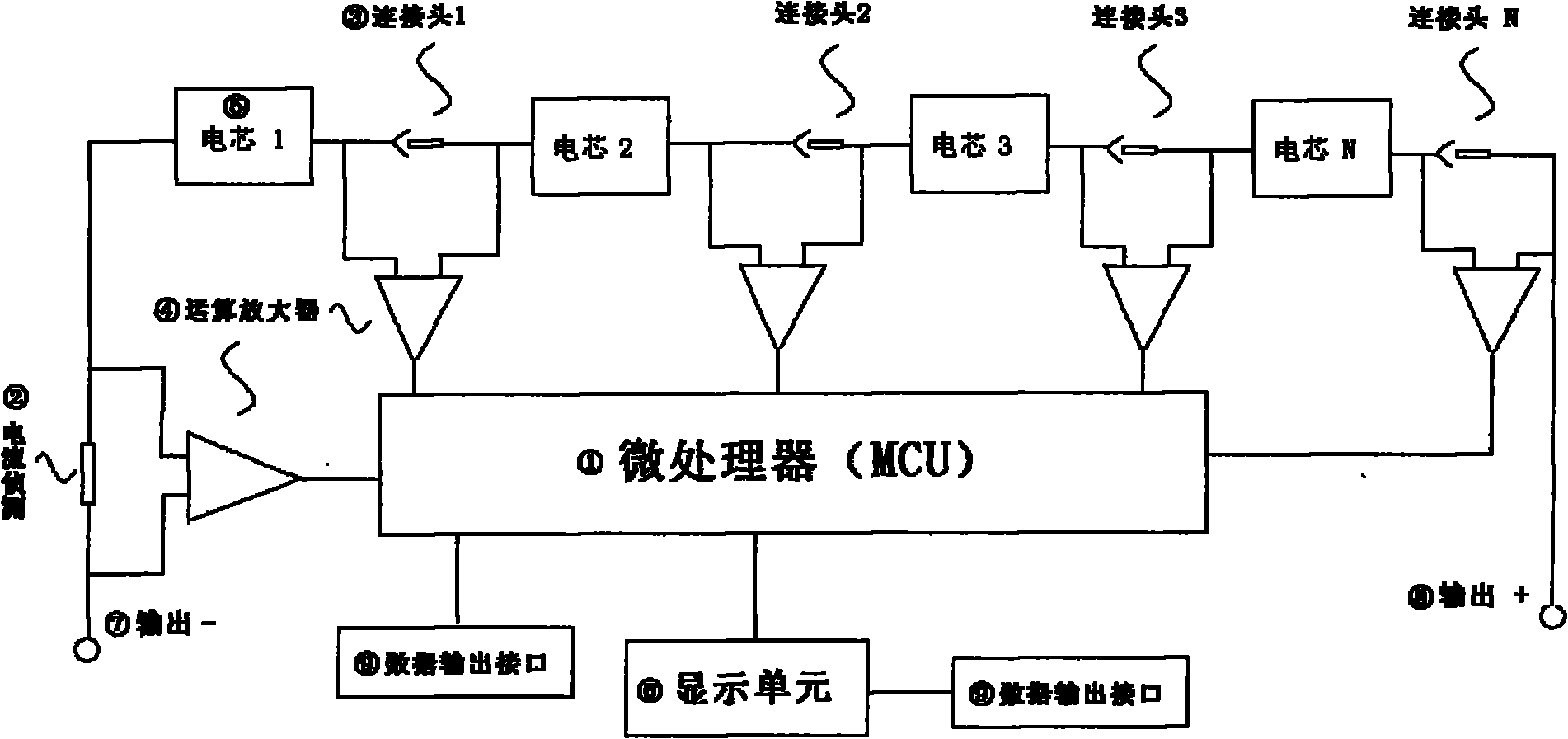

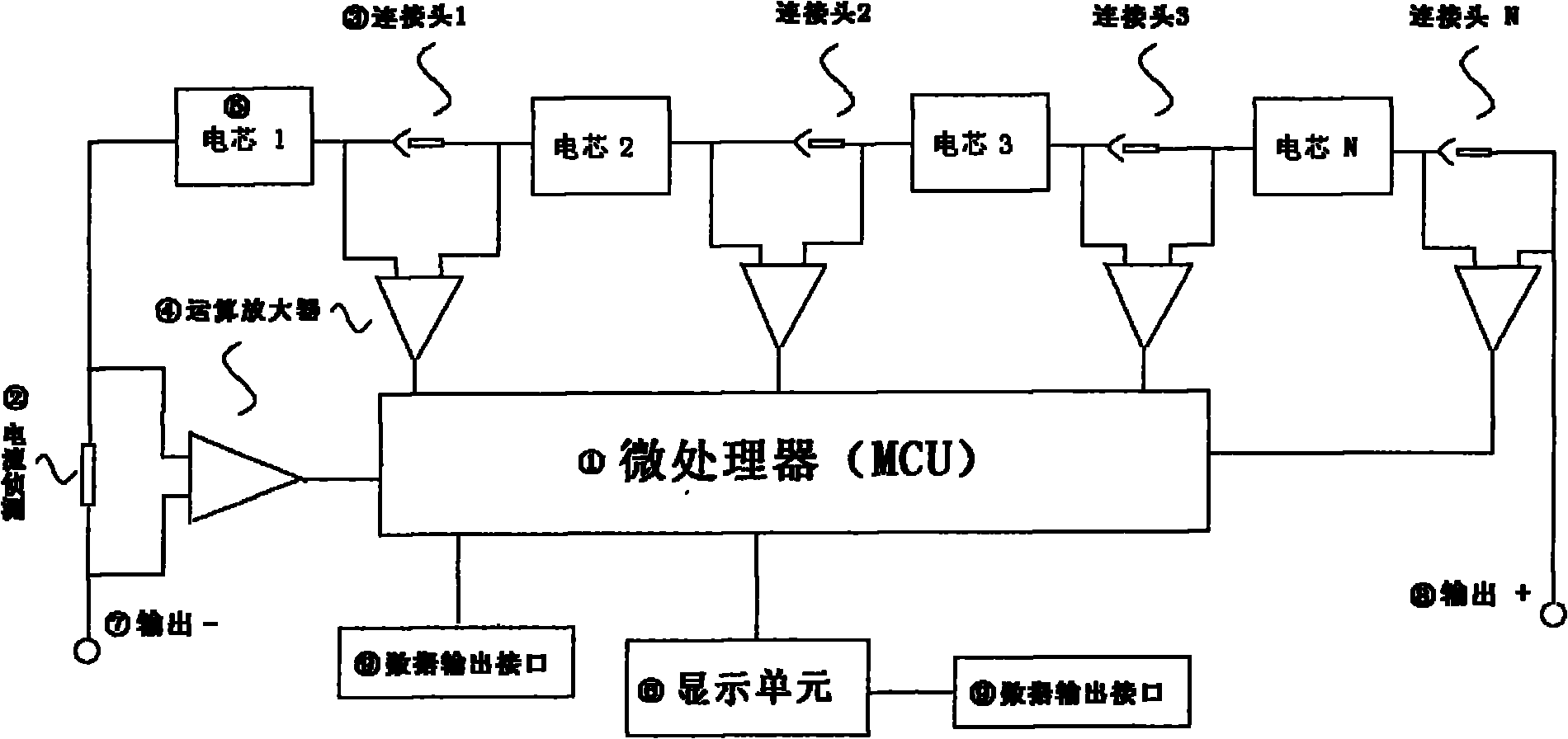

[0030] A method for monitoring the impedance of the connector in a power battery pack, which is used to monitor the impedance change of the connector between the cells that make up the secondary battery pack, such as figure 1 As shown, the typical implementation method is composed of battery core ⑤, connector ③, operational amplifier ④, current monitoring ②, microprocessor ①, display unit ⑥, data output interface ⑨, output + ⑧, output-⑦, etc. It includes the following steps:

[0031] a. Electrical connection: multiple batteries ⑤ are connected in series with connector ③, connector ③, operational amplifier ④, current monitoring ②, microprocessor ①, display unit ⑥, data output interface ⑨ as shown in the electrical properties respectively Connection, output +⑧ and output -⑦ are the power output interfaces of the battery;

[0032] b. Obtain the voltage at both ends of the connector ③: the operational amplifier ④ is connected to both ends of the connector ③ to be monitored, and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com