Controllable low-velocity and large-toque power head motor

A low-speed, high-torque, power head technology, used in fluid pressure actuation devices, drilling equipment and methods, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

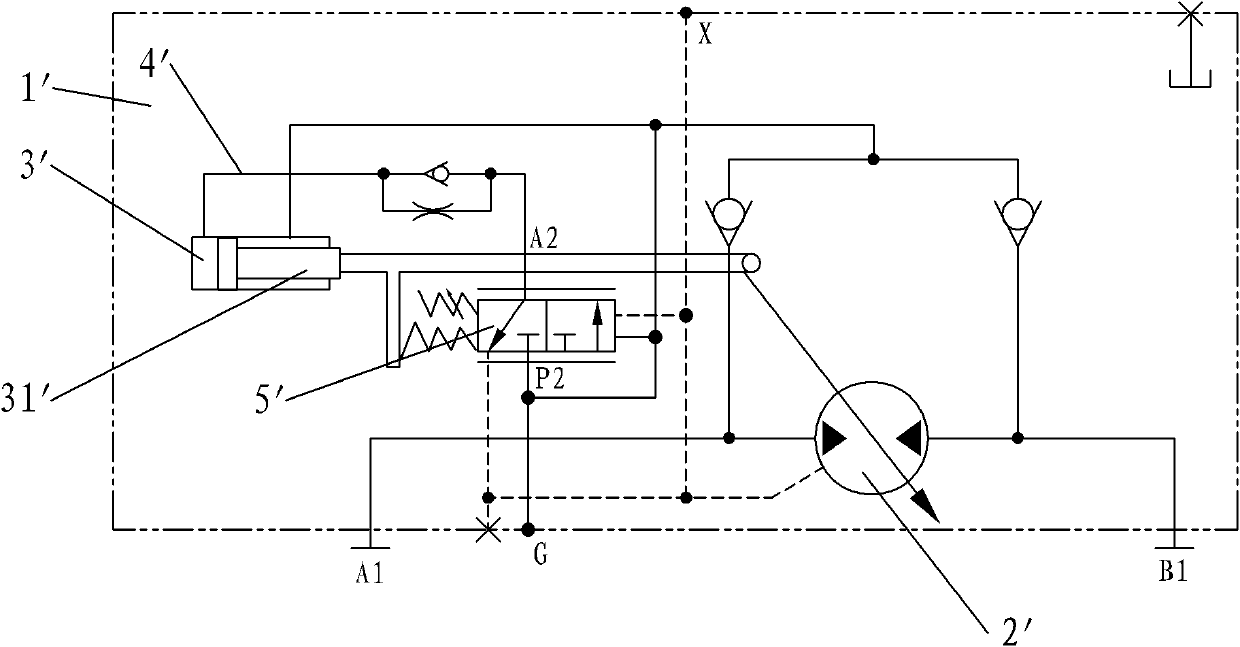

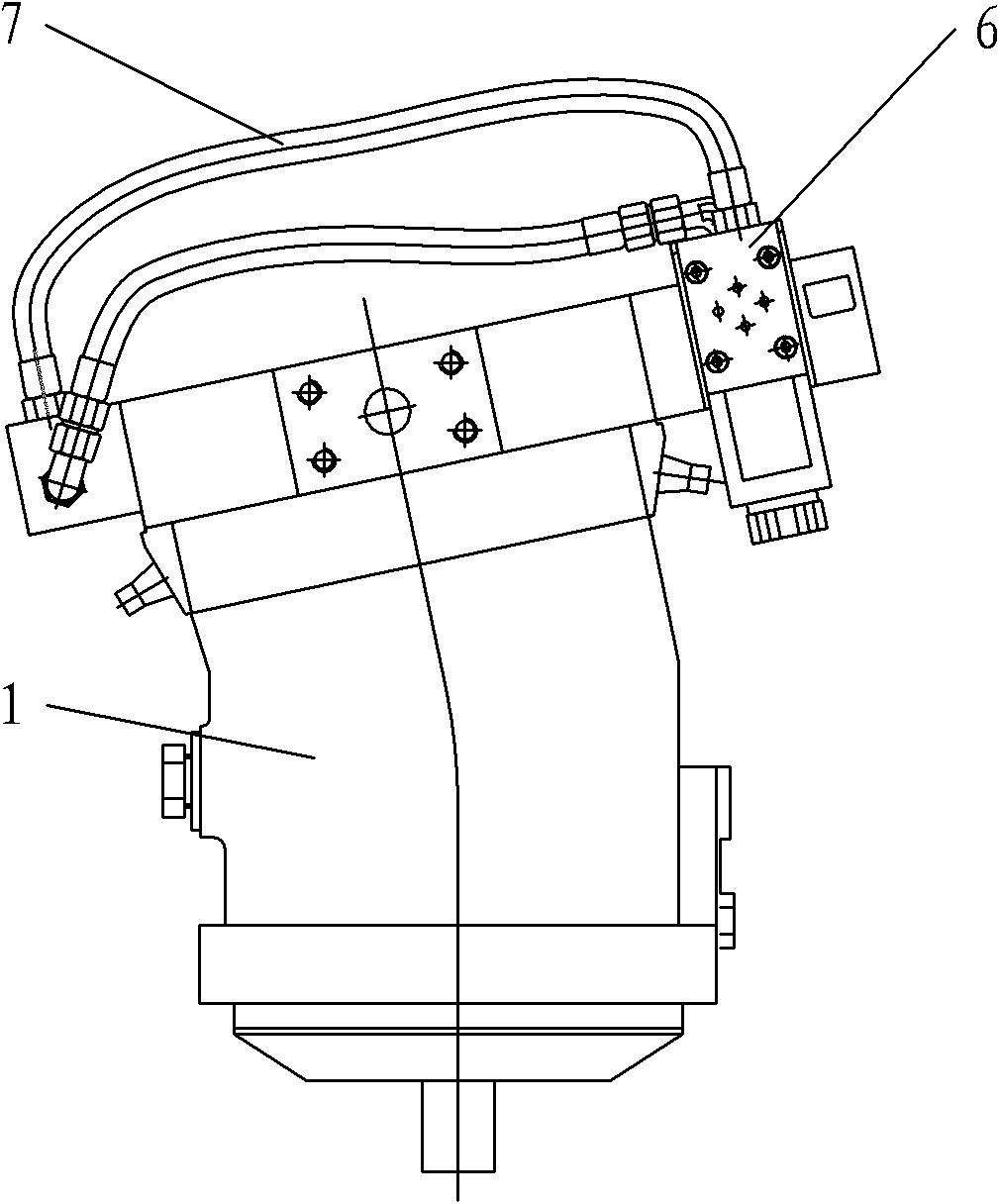

[0015] Such as figure 2 As shown, the controllable low-speed high-torque power head motor of the present invention includes an independent variable motor 1 and a two-position four-way reversing valve 6. The independent variable motor 1 is provided with a plunger motor 2, a variable adjustment piston 3 and a hydraulic control valve. Two-position three-way valve 5, the rod chamber of the variable adjustment piston 3 is connected with the working oil ports A1 and B of the plunger motor 2 through the shuttle valve 1, and the rodless chamber of the variable adjustment piston 3 is connected with the variable adjustment oil circuit 4 Through, the piston rod 31 of the variable adjustment piston 3 is linked with the swash plate of the plunger motor 2, the oil inlet P2 of the hydraulically controlled two-position three-way valve 5 and its right control end are connected with the working oil port A1 of the plunger motor 2 , B1 are connected through the shuttle valve, X port and G port a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com