Glass packing box

A packaging box and glass technology, applied in the field of adjustable set-type glass packaging boxes, can solve the problems of high cost, increased production cost, single size, etc., and achieves the effects of simple production, resource saving and repeated use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings:

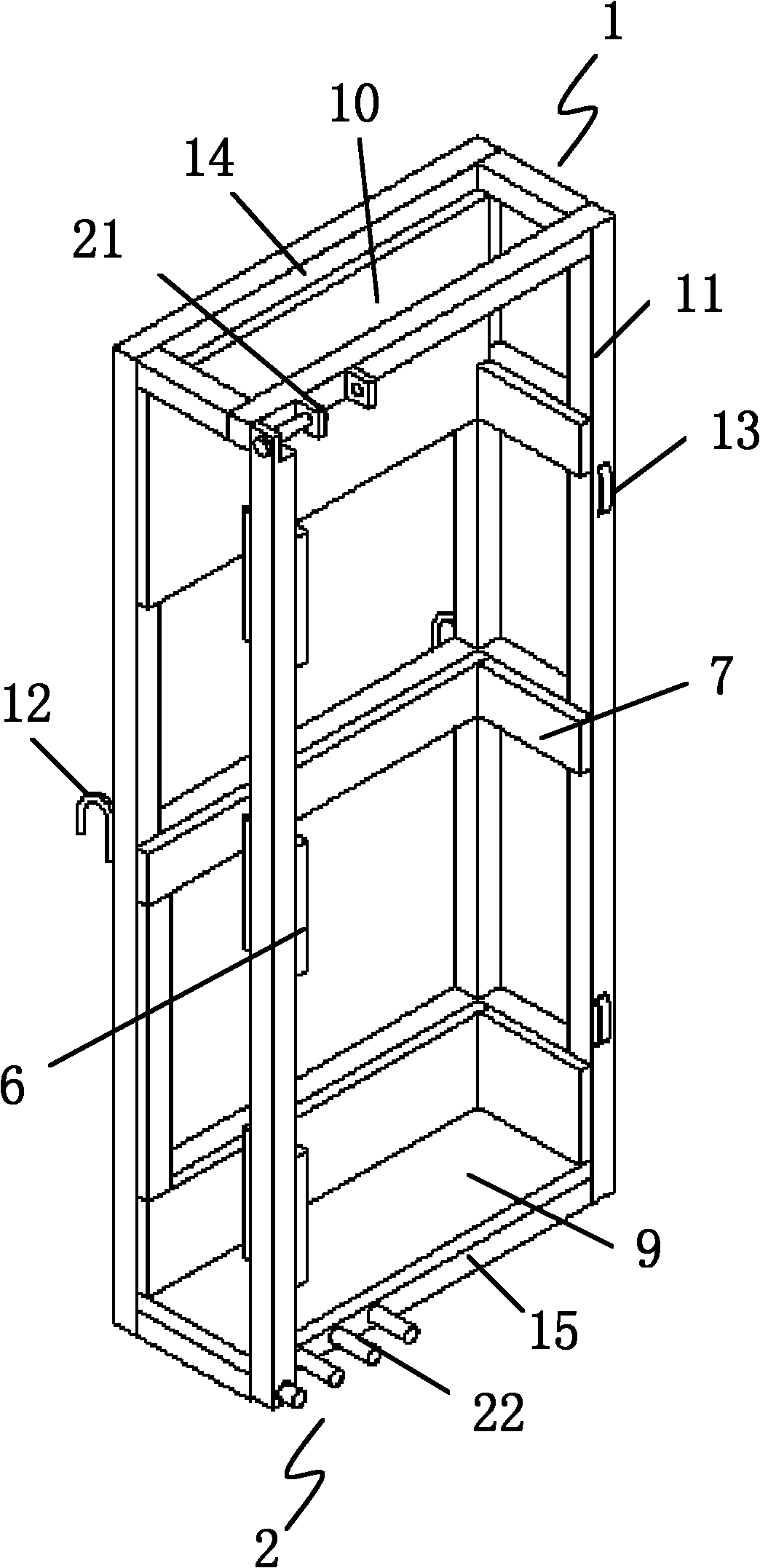

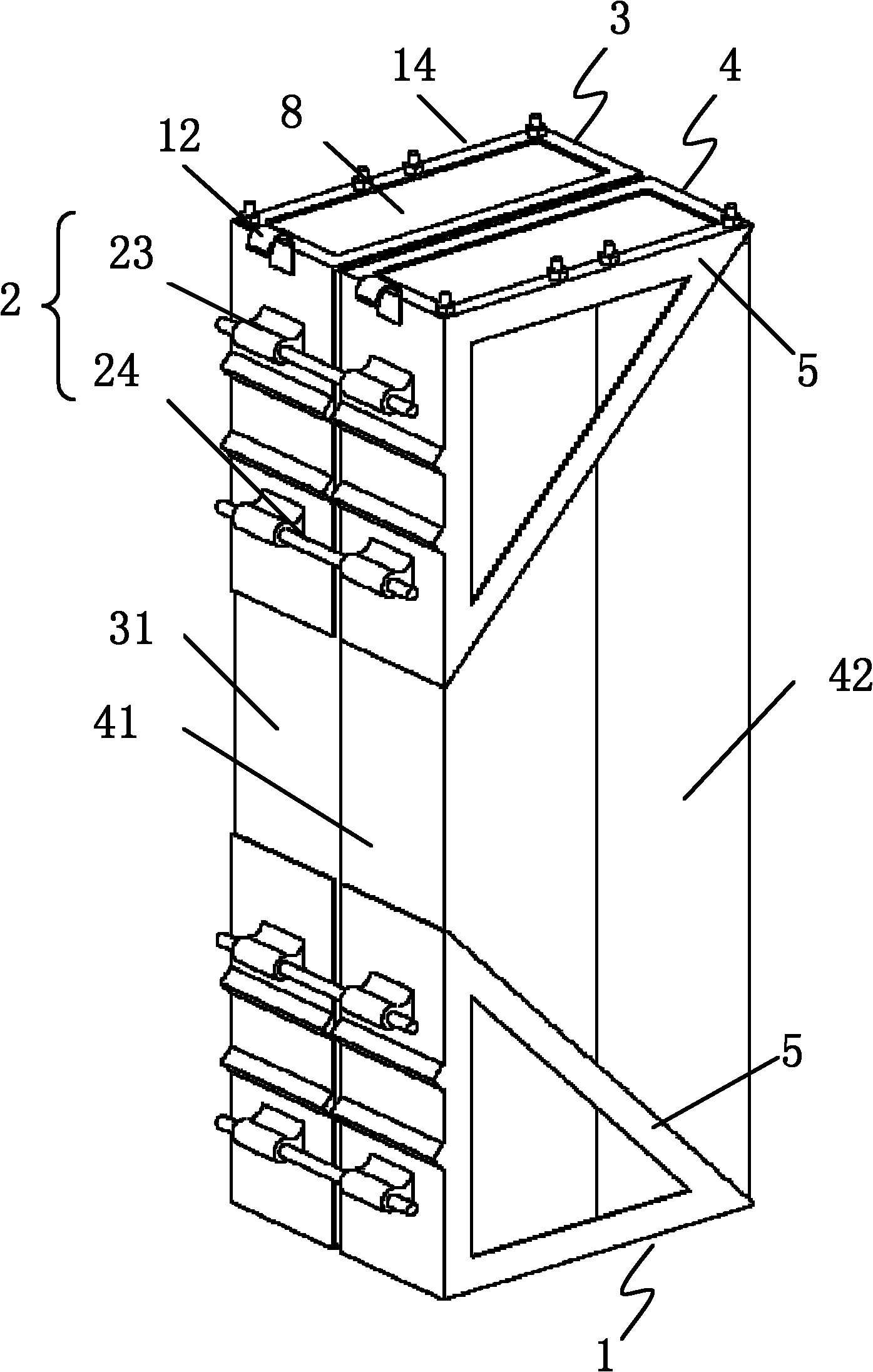

[0039] See figure 1 , figure 1 It is a three-dimensional structural diagram of a glass packaging box according to an embodiment of the present invention. The glass packaging box of the present invention is applied to the packaging and transportation of hollow finished glass. It includes two packaging racks 1, and the two packaging racks 1 are movably arranged in mirror image and symmetrically. For the accommodating space with adjustable length of the packaging glass, each of the packaging racks 1 includes a plurality of uprights 11, a lifting lug 12, a plurality of packing buckles 13, and a plurality of upper and lower connecting rods 14, 15; Two upper and lower connecting rods 14, 15 connect the plurality of uprights 11 into a rectangular frame structure. In this embodiment, specifically, four upper connecting rods 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com