Recirculation unit and method for waste leachate or concentrate thereof

A technology of landfill leachate and concentrate, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult formation of aerobic conditions, poor vertical permeability, unfavorable removal of ammonia nitrogen, etc. problems, achieve good ventilation, solve poor permeability, and facilitate removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A landfill in Yichang produces an average of 240 tons of landfill leachate per day. The leachate treatment plant was built and put into use in January 2009. It processes 240 tons of landfill leachate per day, discharges 188 tons of clear water per day after treatment, and produces 52 tons of concentrated liquid. The concentrated solution adopts the gabion recharging treatment of the present invention, and the concentrated solution is transported to each recharging unit for recharging with a recharging tank car. There are 10 recharging units in the landfill, and each recharging unit has a service area of 200m 2 .

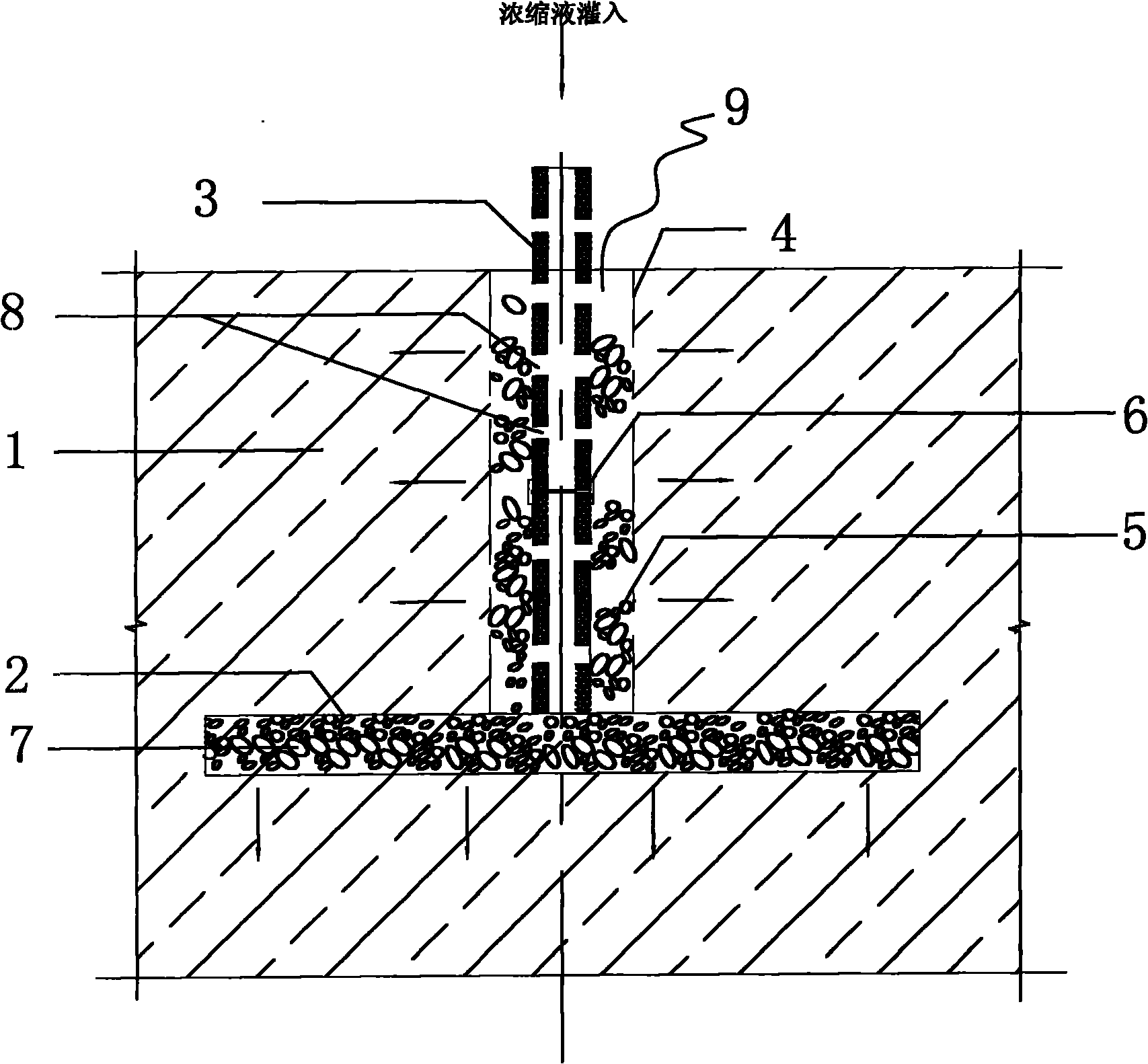

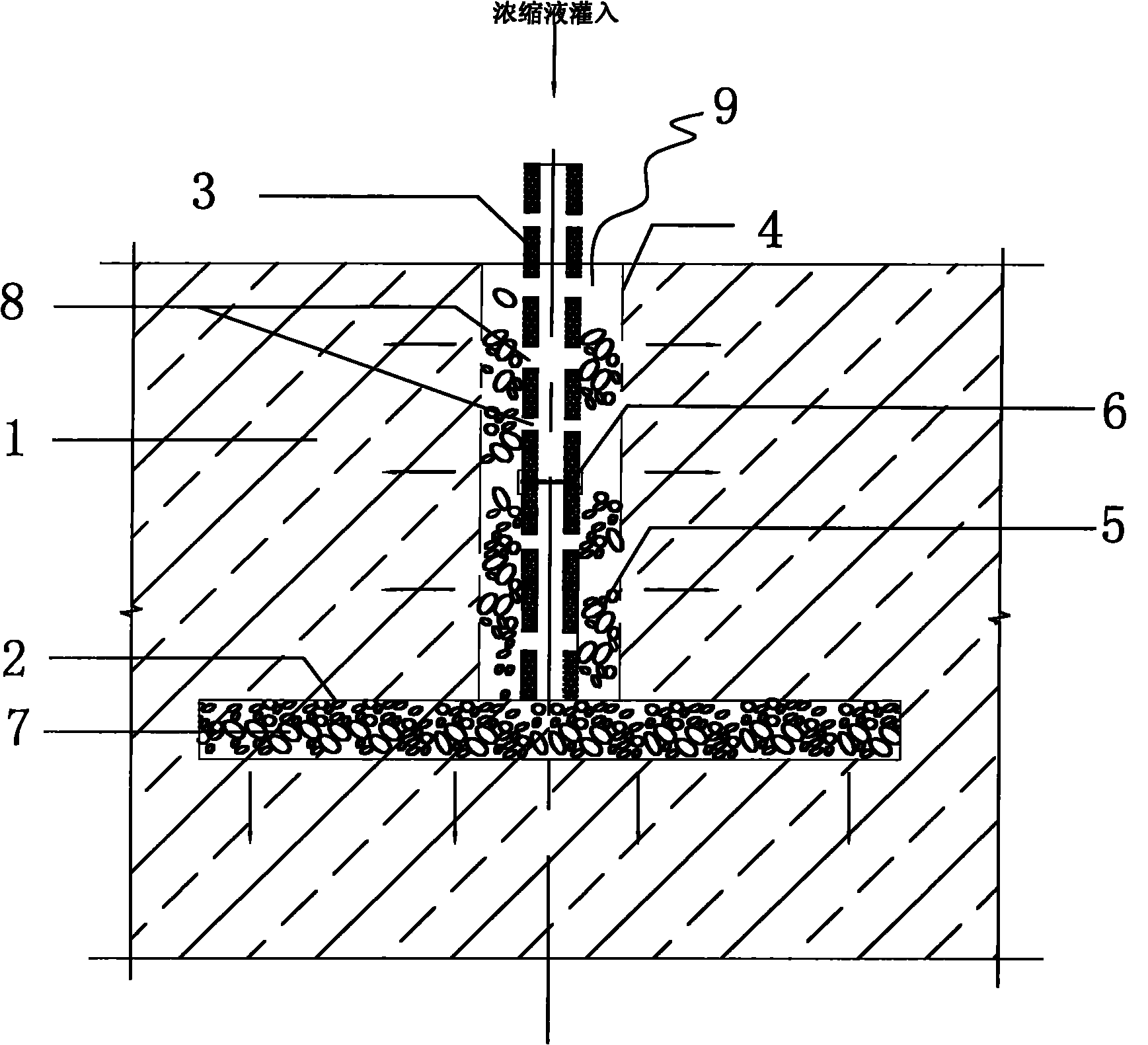

[0028] Such as figure 1 As shown, the water distribution layer 2 of each recharge unit is composed of the second-level matching stone 7, which is a low-calcium pebble with a diameter of 32-64 mm, and the water distribution layer 2 is sandwiched in the garbage layer 1. The polypropylene hollow tube perpendicular to and connected to the water distribution lay...

Embodiment 2

[0030] A landfill in Tieling produces an average of 150 tons of landfill leachate per day. The leachate treatment plant was built in September 2009. It processes 150 tons of landfill leachate per day, discharges 112.5 tons of clear water per day after treatment, and produces 37.5 tons of concentrated liquid. For recharge treatment, use the recharge pump to lift the permeate to each recharge area for recharge. There are 8 recharge units in the landfill, and each recharge unit has a service area of 200m 2 , wherein the structure of each recharge unit is the same as that of Embodiment 1, and the steps are:

[0031] (1) When the garbage layer reaches a certain thickness, build a water distribution layer. Each water distribution layer is composed of second-level matching stones. The second-level matching stones are low-calcium pebbles with a diameter of 32-64mm. The water distribution layer is sandwiched within the garbage layer;

[0032] (2) Set up a recharge channel with sever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com