Heat exchanger structure and assembly method thereof

An assembly method and heat exchanger technology, applied in heat exchange equipment, evaporator/condenser, lighting and heating equipment, etc., to achieve the effects of easy assembly, avoiding brazing, and saving welding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

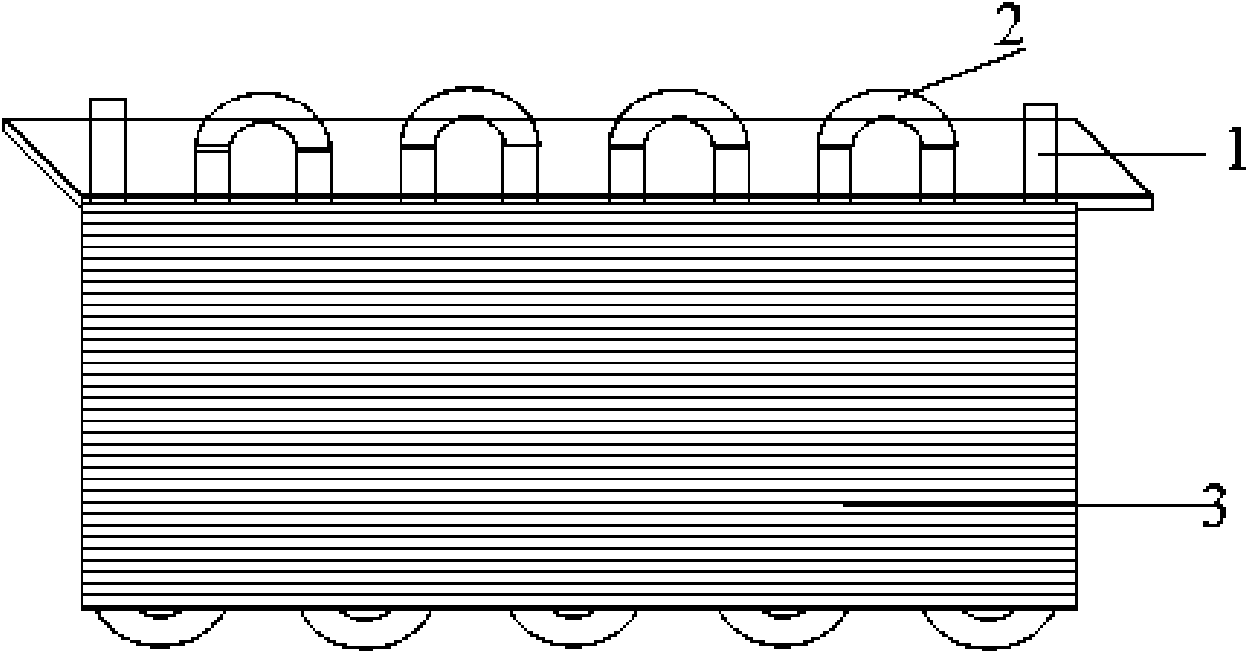

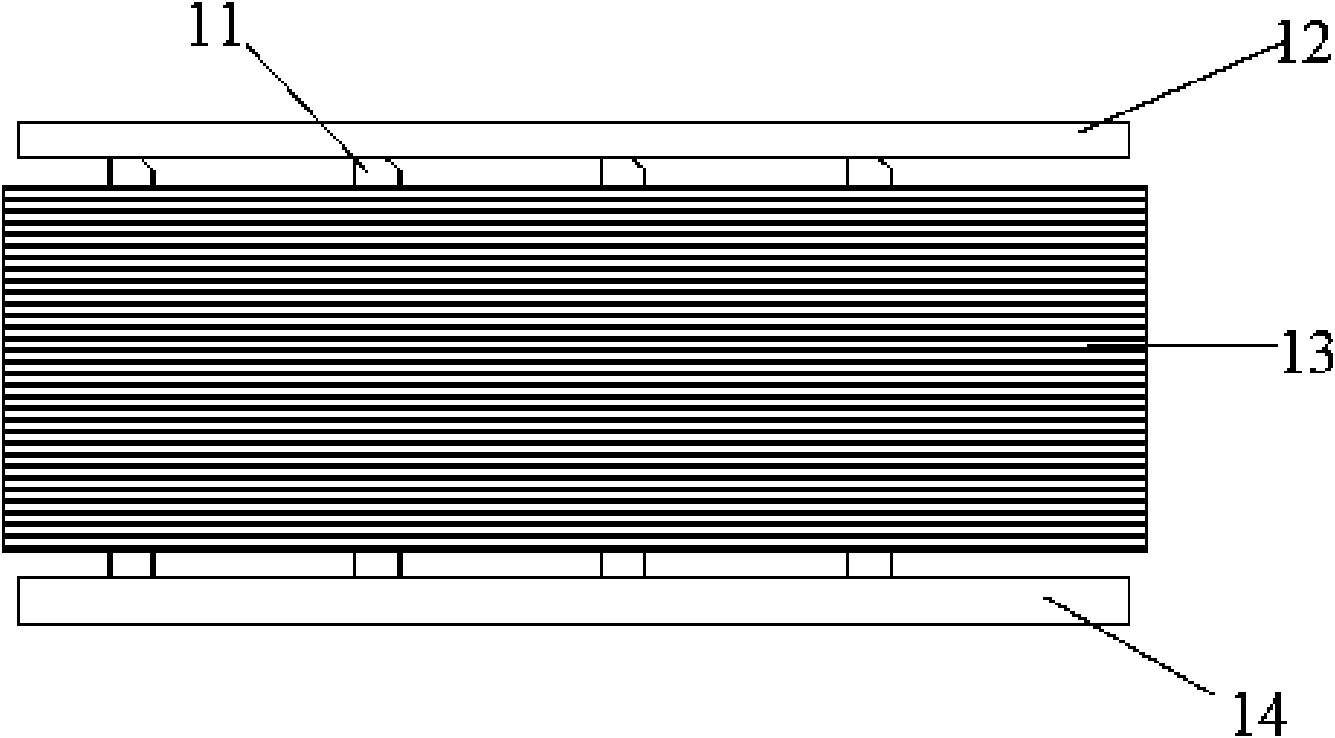

[0025] The structure of the heat exchanger of the present invention will be further described below with reference to the accompanying drawings.

[0026] figure 2 As shown, the heat exchanger structure of the present invention includes an inlet header 12, an outlet header 14, fins 13 that are tightly stacked between the inlet header 12 and the outlet header 14, and through the fins 13 the inlet header 12 and the flat tube 11 connected to the outlet header 14, the flat tube is generally an aluminum flat tube, its cross section is a rounded rectangular structure, and a plurality of partition plates are arranged in the lumen, and the partition plates are arranged along the flat The tube extends in the pipeline direction and evenly divides the lumen into several microchannels that are not connected to each other; it also includes gaskets that are sleeved on the flat tube and arranged on both sides of the fins 13 .

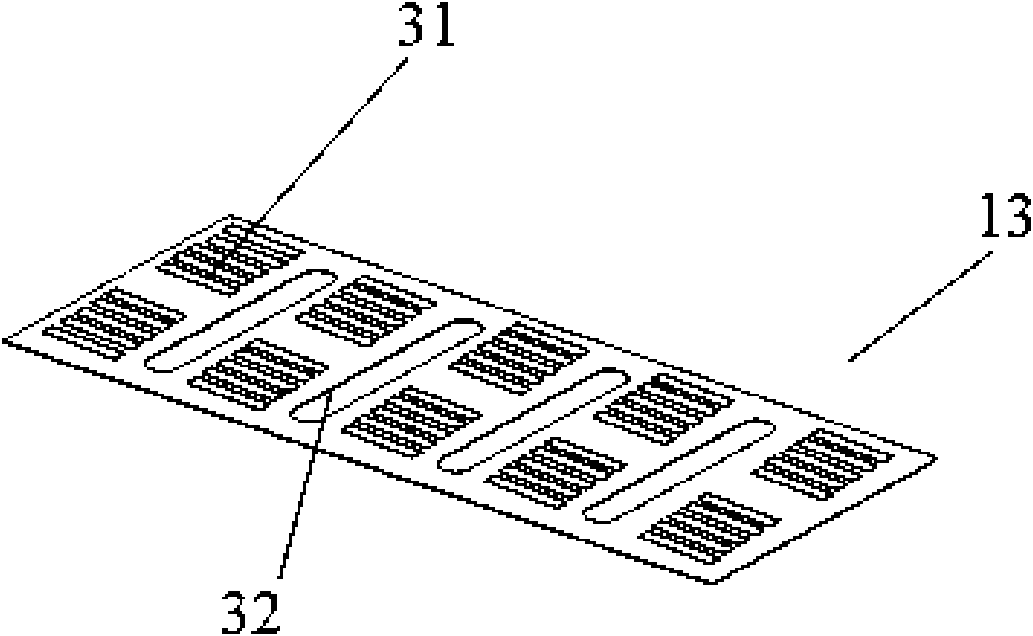

[0027] image 3 Shown is the structure of the fin 13 of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com