Flat plate gripping and releasing device

A release device and flat panel technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low work efficiency, inaccurate positioning, etc., and achieve the effect of fast grabbing or releasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

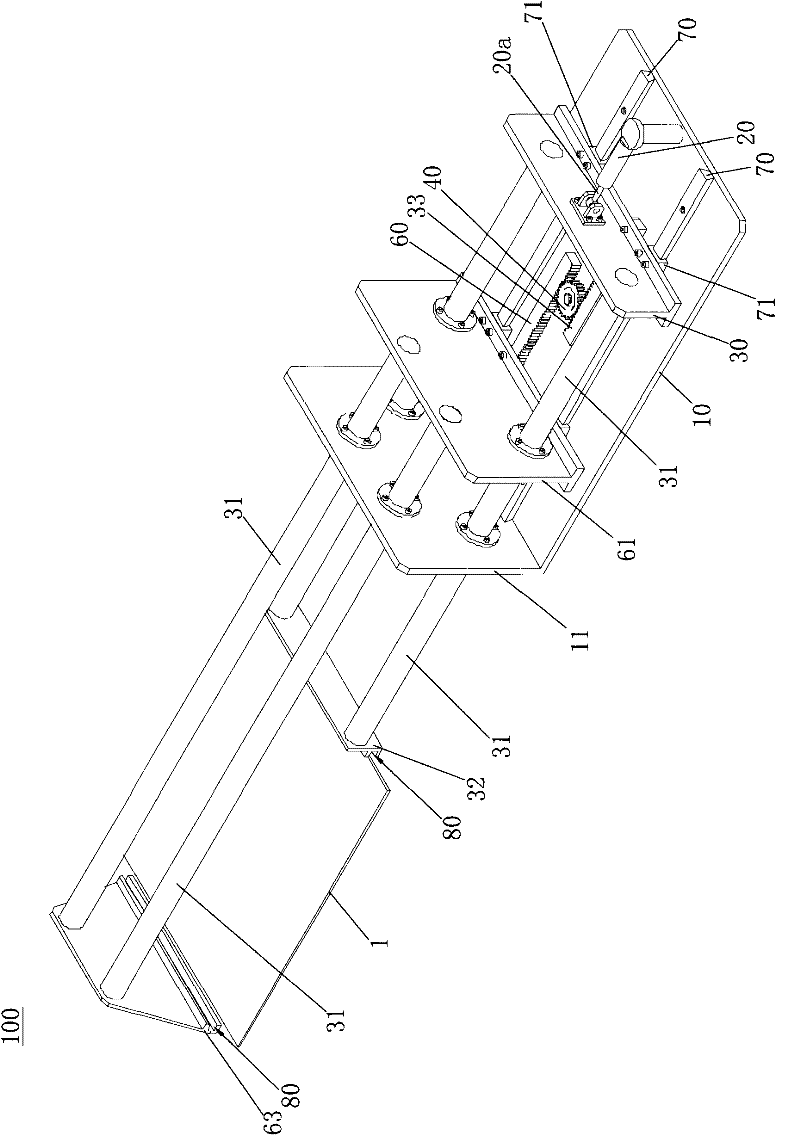

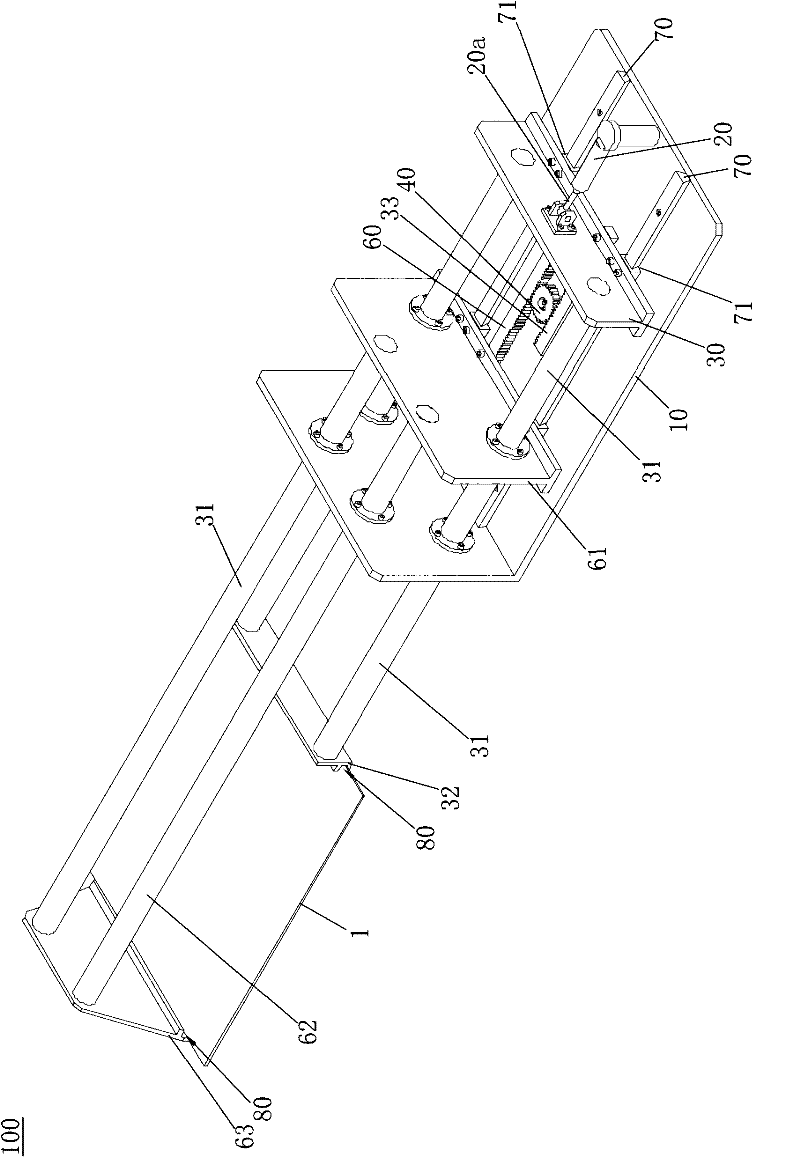

[0017] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as Figure 1-3 As shown, the tablet grabbing and releasing device 100 provided by the present invention includes a fixed plate 10, a driving cylinder 20, an inner grip driving plate 30, an inner grip 32, an inner grip driving rack 33, a gear 40, and an outer grip driving Plate 61 , outer gripper 63 and outer gripper drive rack 60 .

[0018] The fixed plate 10 is placed horizontally, the driving cylinder 20 is fixedly connected with the fixed plate 10, the connecting rod 20a of the driving cylinder 20 is connected with the inner gripper driving plate 30, and the inner gripper driving plate 30 and the outer grip driving plate 61 are parallel to each other, and are all slidably connected to the fixed plate 10, specifically, the fixed plate 10 is provided with a slide rail parallel to the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com